Check out our leading manufacturer for the professional solution here:

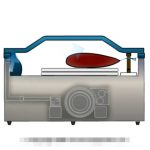

Are you in the market for a high-quality powder filling machine that can streamline your bag-making, weighing, filling, nitrogen-filling, date coding, and bag-cutting processes? Look no further than the Powder Filling Packing Machine! In this YouTube video, we will dive into the features and benefits of this innovative machine, highlighting its capabilities and how it can revolutionize your packaging operations.

Opinion/Thought Piece Style:

Have you ever struggled with the time-consuming and labor-intensive task of filling powder into bags? If so, you’re not alone. Many businesses face challenges when it comes to efficient and accurate powder filling. This is where the Powder Filling Packing Machine comes in. With its advanced technology and user-friendly design, this machine can significantly improve your production efficiency and reduce human error.

Interview Style:

In a recent interview, a satisfied customer shared their experience with the Powder Filling Packing Machine. They emphasized how this machine has transformed their packaging process, enabling them to fill bags with powder quickly and precisely. The customer praised the machine’s ability to handle various types of powders, ensuring consistent and reliable results every time.

Case Study Style:

Let’s take a closer look at a real-life case study that demonstrates the effectiveness of the Powder Filling Packing Machine. ABC Company, a leading manufacturer of powdered supplements, was struggling with bottlenecks in their packaging line. Their manual filling process was slow, prone to errors, and hindered their overall productivity. After implementing the Powder Filling Packing Machine, ABC Company experienced a significant improvement in their packaging operations. Not only did the machine increase their production speed, but it also enhanced the accuracy of their powder filling, resulting in greater customer satisfaction.

Predictive/Foresight Style:

As the demand for powdered products continues to rise, businesses need to stay ahead of the competition by investing in advanced packaging solutions. The Powder Filling Packing Machine is a game-changer in the industry, offering a holistic solution to streamline the entire packaging process. By automating bag-making, weighing, filling, nitrogen-filling, date coding, and bag-cutting, this machine eliminates the need for multiple manual steps, saving time and reducing labor costs. With its accuracy and efficiency, the Powder Filling Packing Machine is poised to become an essential asset for businesses looking to stay competitive in the market.

Technology History Style:

From the early days of manual powder filling to the modern era of automation, the packaging industry has come a long way. The Powder Filling Packing Machine represents the pinnacle of technological advancements in the field. By integrating cutting-edge features such as pneumatic double screws and precise date coding capabilities, this machine combines convenience, efficiency, and accuracy like never before. Say goodbye to the tedious and error-prone manual powder filling methods of the past and embrace the future with the Powder Filling Packing Machine.

In-depth Analysis Style:

When it comes to selecting a powder filling machine, it’s crucial to consider various factors such as speed, accuracy, versatility, and ease of use. The Powder Filling Packing Machine excels in all these areas. Its pneumatic double screw system ensures consistent and precise filling, while the nitrogen-filling feature helps maintain the freshness and quality of the powder. Additionally, the machine’s ability to perform bag-making, weighing, date coding, and bag-cutting eliminates the need for separate equipment, making it a cost-effective and space-saving solution for businesses of all sizes.

How-to Guide Style:

Are you ready to revolutionize your powder filling process? Here’s a step-by-step guide on how to use the Powder Filling Packing Machine:

1. Set up the machine according to the provided instructions and ensure all necessary components are properly connected.

2. Prepare the bags by adjusting the bag-making and bag-cutting settings to meet your specific requirements.

3. Calibrate the weighing system to ensure accurate measurements.

4. Load the powder into the machine’s hopper and adjust the filling speed and weight settings.

5. Activate the machine and let it automatically perform bag-making, weighing, filling, nitrogen-filling, date coding, and bag-cutting.

6. Monitor the process and make any necessary adjustments based on your desired specifications.

7. Once the bags are filled, sealed, and coded, remove them from the machine and prepare them for distribution.

With this comprehensive guide, you’ll be able to maximize the potential of the Powder Filling Packing Machine and optimize your packaging operations.

Check the coil packing solution with our leading manufacturer for the professional solution just here: Filling Packing Machine

“Efficient and Precise Powder Filling Solutions: Pneumatic Double Screw and Bulk Bag Packing Machine”