Title: Fully Automatic Silicone Sealant Production Line | Automatic Packing Line Manufacturers

Description:

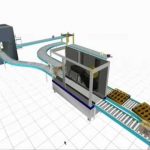

Welcome to our channel! In this video, we will showcase the state-of-the-art fully automatic silicone sealant production line offered by Automatic Packing Line Manufacturers. Our production line is equipped with advanced technology for cartridge packaging and sausage packaging, providing efficient and precise solutions for the sealant industry.

Junbond Group, a renowned player in the silicone sealant market, takes pride in being ranked among the top 3 sealant manufacturers in China. With over 14 years of experience in the industry, we have established ourselves as experts in producing high-quality silicone sealants.

In this video, we will take you through the entire process of our fully automatic silicone sealant production line. From raw material handling to the final packaging, we will demonstrate the operation steps, highlighting the key points and interesting facts about our production line.

Our automated production line ensures consistent product quality, increased productivity, and reduced labor costs. With precise control over the entire manufacturing process, we guarantee the highest level of accuracy and efficiency in silicone sealant production.

Our team of skilled professionals has meticulously designed this production line to meet the growing demands of the sealant industry. By incorporating cutting-edge technology and innovative features, we have created a reliable and user-friendly system that maximizes productivity while minimizing downtime.

Join us in this video to witness the seamless operation of our fully automatic silicone sealant production line. Whether you are a sealant manufacturer looking to upgrade your production facility or an enthusiast eager to explore the latest innovations in the industry, this video is a must-watch.

If you find this video informative, don’t forget to hit the like button and subscribe to our channel for more insightful content. Feel free to share this video with your colleagues and friends who might be interested in the sealant industry.

Additional Tags: automatic packing line, silicone sealant production, cartridge packaging, sausage packaging, Junbond Group, sealant industry, China, production line, automated manufacturing, efficiency, productivity, innovation

Hashtags: #AutomaticPackingLine #SiliconeSealantProduction #JunbondGroup #SealantIndustry #FullyAutomaticProductionLine

A tilter for a fully automatic silicone sealant production line with cartridge packaging and sausage packaging is designed to efficiently handle and transport the sealant containers throughout the production process. The tilter should be capable of tilting the cartridges and sausages to facilitate filling, labeling, and packaging operations.

Here is a suggested tilter design:

1. Structure:

– The tilter should have a sturdy and stable structure made of high-quality materials to withstand the weight and pressure exerted during the tilting process.

– It should be equipped with safety features such as emergency stop buttons, sensors, and protective guards to ensure operator safety.

2. Tilting Mechanism:

– The tilter should have a motorized tilting mechanism that can tilt the containers smoothly and accurately.

– The tilting angle should be adjustable to accommodate different production requirements.

– The tilting speed should be controllable to ensure precise and controlled movements.

3. Cartridge Tilting:

– The tilter should have adjustable holders or clamps to securely hold the cartridges during the tilting process.

– It should be capable of tilting the cartridges to a predetermined angle for easy filling, labeling, and packaging.

– The tilting mechanism should provide a gentle motion to prevent any spillage or damage to the sealant.

4. Sausage Tilting:

– The tilter should have adjustable holders or clamps to securely hold the sausages during the tilting process.

– It should be capable of tilting the sausages to a specific angle to facilitate filling, labeling, and packaging.

– The tilting mechanism should be designed to handle sausages of different sizes and weights.

5. Control System:

– The tilter should be equipped with an intuitive control panel or interface to allow operators to easily set the desired tilting angle and speed.

– It should have a PLC (Programmable Logic Controller) or a similar system to automate the tilting process.

– The control system should provide real-time monitoring and feedback on the tilting operation.

6. Integration:

– The tilter should be seamlessly integrated into the fully automatic silicone sealant production line.

– It should have compatible interfaces and connections to communicate with other machines, such as filling machines, labeling machines, and packaging machines.

– The tilter should have the necessary sensors and actuators to synchronize its operation with other production line components.

By incorporating these features, the tilter for the fully automatic silicone sealant production line with cartridge packaging and sausage packaging will enhance the efficiency and productivity of the production process, ensuring smooth and accurate tilting of the containers for filling, labeling, and packaging operations. coil packing line

#Fully #automatic #silicone #sealant #production #line #cartridge #packaging #sausage #packaging