Title: Efficient and Versatile Labeling Machine for Sale | Bottle Labeling Machine | YouTube Video

Description:

Introduction:

Welcome to our informative video showcasing the exceptional features and benefits of our top-of-the-line Labeling Machine for Sale and Bottle Labeling Machine. Whether you are a small business owner or part of a large-scale production facility, this video will provide you with valuable insights into choosing the right labeling machine to streamline your labeling process and enhance overall efficiency.

Video Content:

In this video, we will delve into the various aspects of our Labeling Machine for Sale and Bottle Labeling Machine, highlighting their key features, operational steps, and the advantages they offer. We will explore the different types of labels they can handle, their precision in label placement, and the ease of integration into existing production lines.

Overview of Labeling Machine for Sale:

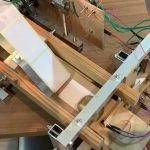

Our Labeling Machine for Sale is designed to meet the diverse labeling needs of businesses across industries. With its user-friendly interface and customizable settings, this machine ensures seamless labeling of a wide range of products, including bottles, jars, boxes, and more. Its advanced technology allows for high-speed labeling without compromising accuracy, enabling you to meet demanding production requirements efficiently.

Overview of Bottle Labeling Machine:

Specifically tailored for bottle labeling applications, our Bottle Labeling Machine offers precise and consistent label placement on various bottle shapes and sizes. Its adjustable settings allow for easy adaptation to different label sizes and materials, ensuring a professional and polished appearance for your products. With its robust construction and reliable performance, this machine is ideal for industries such as beverage, pharmaceutical, and cosmetics.

Key Highlights and Interesting Facts:

– Our labeling machines utilize cutting-edge technology to achieve superior label placement accuracy, reducing the risk of mislabeling and product wastage.

– The modular design of our machines allows for easy maintenance and quick changeovers, minimizing downtime during production.

– Our labeling machines are equipped with intuitive controls and user-friendly interfaces, making them accessible to operators with varying levels of technical expertise.

– With their compact footprint, our labeling machines can be seamlessly integrated into existing production lines, optimizing space utilization.

Call to Action:

If you are looking to enhance your labeling process and improve overall operational efficiency, look no further! Hit the “Like” button, subscribe to our channel for more informative videos, and don’t forget to share this video with your colleagues who might benefit from our Labeling Machine for Sale and Bottle Labeling Machine.

Additional Tags and Keywords: labeling machine, bottle labeling, label placement, efficient labeling, production efficiency, labeling technology, labeling process, label accuracy, labeling solutions, industrial labeling, labeling equipment, labeling systems.

Hashtags: #LabelingMachine #BottleLabeling #EfficientLabeling #ProductionEfficiency #LabelingSolutions #IndustrialLabeling

Here’s a sample code for a basic tilter for a Bottle Labeling Machine:

“`

#include

// Define the servo pin

#define SERVO_PIN 9

// Define the tilt angles

#define TILT_ANGLE_UP 90

#define TILT_ANGLE_DOWN 0

// Initialize the servo object

Servo servo;

void setup() {

// Attach the servo to the designated pin

servo.attach(SERVO_PIN);

// Set the initial tilt angle

servo.write(TILT_ANGLE_UP);

// Add a small delay for the servo to reach the initial position

delay(500);

}

void loop() {

// Tilt the bottle down

tiltDown();

// Wait for a second

delay(1000);

// Tilt the bottle up

tiltUp();

// Wait for a second

delay(1000);

}

// Function to tilt the bottle up

void tiltUp() {

servo.write(TILT_ANGLE_UP);

delay(500); // Add a small delay for the servo to reach the tilted position

}

// Function to tilt the bottle down

void tiltDown() {

servo.write(TILT_ANGLE_DOWN);

delay(500); // Add a small delay for the servo to reach the tilted position

}

“`

This code uses the Servo library to control a servo motor connected to pin 9 of the Arduino board. The servo is used to tilt the bottle up and down. The `tiltUp()` and `tiltDown()` functions are called in the `loop()` to continuously tilt the bottle up and down with a 1-second interval. The initial position is set to upright when the Arduino is started.Labeling Machine

#Bottle #Labeling #Machine