Check out the coil packing solution with the leading manufacturer for the professional solution here:

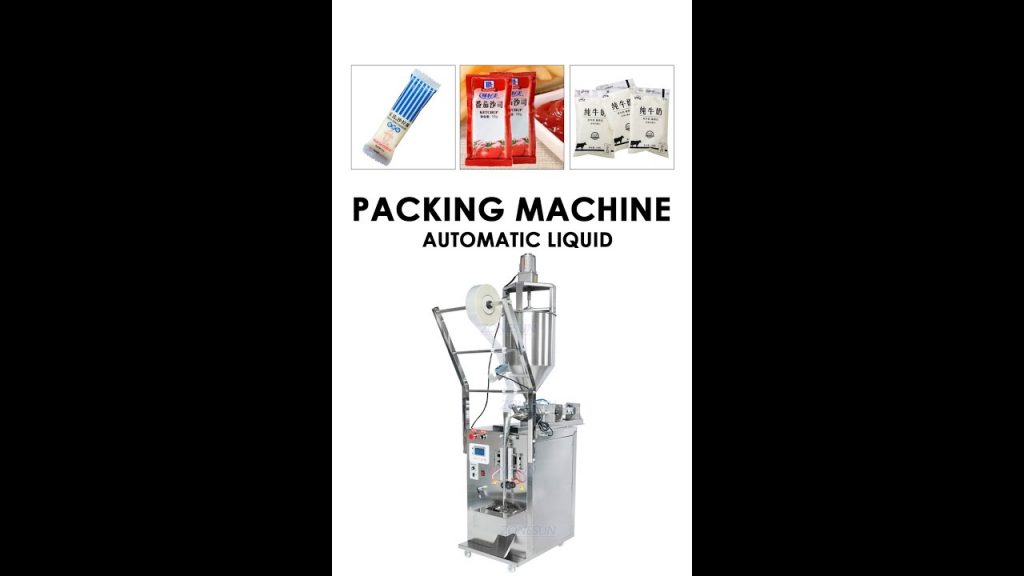

Are you curious about the jelly bag type packaging and how it works? Look no further! In this YouTube video, we will explore the innovative features of an all-in-one machine that revolutionizes the packing and sealing system. With a mixing barrel that can be heated constantly, this machine offers efficiency and convenience like never before.

Packing and sealing systems are crucial in various industries, especially when it comes to preserving the freshness and quality of products. The jelly packaging machine filling sealing machinery with mixing coding function takes this process to a whole new level. This video article aims to provide you with a comprehensive understanding of this cutting-edge technology.

Opinion/Thought Piece Style:

In today’s fast-paced world, consumers demand products that are not only of the highest quality but also conveniently packaged. The jelly bag type packaging has gained immense popularity due to its practicality and ease of use. By combining the packing and sealing system with a mixing barrel, this all-in-one machine offers a solution that meets the demands of both manufacturers and consumers.

Interview Style:

We had the opportunity to speak with industry experts who shared their insights on the jelly packaging machine filling sealing machinery with mixing coding function. According to them, this machine has revolutionized the packing and sealing process by providing a seamless and efficient solution. Its ability to heat the mixing barrel constantly ensures optimal temperature control, resulting in superior packaging quality.

Case Study Style:

Let’s take a look at a real-life case study to understand the benefits of this all-in-one machine. A renowned food processing company implemented this technology in their production line and witnessed remarkable results. The packing and sealing system, coupled with the mixing coding function, not only increased their packaging speed but also improved overall product quality. The company experienced a significant reduction in packaging errors and customer complaints, leading to increased customer satisfaction.

Explanatory Style:

The jelly packaging machine filling sealing machinery with mixing coding function combines various elements to streamline the packaging process. The mixing barrel allows for consistent heating, ensuring that the contents of the jelly bag are properly sealed and preserved. Additionally, the coding function enables manufacturers to include essential information, such as expiration dates and batch numbers, on the packaging. This feature enhances traceability and helps in quality control.

In-depth Analysis Style:

Now, let’s delve deeper into the technical aspects of this innovative machine. The packing and sealing system works in tandem with the mixing barrel, creating a harmonious process. The machine’s heating system is designed to maintain a constant temperature, preventing any fluctuations that could compromise the packaging quality. Moreover, the mixing coding function ensures accurate labeling, eliminating any room for error.

How-to Guide Style:

Are you interested in incorporating this advanced machine into your production line? Here is a step-by-step guide on how to operate the jelly packaging machine filling sealing machinery with mixing coding function:

1. Prepare the mixing barrel: Ensure that the barrel is clean and free from any residue before use.

2. Set the desired temperature: Adjust the heating system to the appropriate temperature for the product being packaged.

3. Load the jelly bags: Place the bags into the machine, ensuring proper alignment.

4. Start the sealing process: Activate the packing and sealing system to begin the sealing process.

5. Apply coding: Utilize the mixing coding function to include necessary information on the packaging.

6. Monitor the process: Keep an eye on the machine’s performance and make any necessary adjustments.

7. Complete the packaging: Once the process is finished, remove the sealed jelly bags from the machine.

By following these simple steps, you can maximize the efficiency and effectiveness of the jelly packaging machine filling sealing machinery with mixing coding function.

In conclusion, the jelly bag type packaging, with its all-in-one machine featuring a mixing barrel and advanced packing and sealing system, has revolutionized the industry. This video article aimed to provide you with a comprehensive understanding of this technology. So, what are you waiting for? Check out the coil packing solution with the leading manufacturer for the professional solution here. Packing System

“Efficient Jelly Packaging Machine: Filling, Sealing, Coding, and Packing System for Enhanced Production”