Are you in need of a reliable and efficient semi-automatic plastic injection machine? Look no further! In this YouTube video, we will explore the features and benefits of using a semi-automatic plastic injection machine. Whether you are a small business owner or a large manufacturer, this machine can revolutionize your plastic injection molding process.

Title: Enhance Your Plastic Injection Molding Process with a Semi-Automatic Plastic Injection Machine

Introduction:

Welcome to our YouTube video where we will introduce you to the world of semi-automatic plastic injection machines. If you are looking to streamline your plastic injection molding process, increase production efficiency, and reduce costs, this machine is for you. Let’s dive in!

Section 1: Understanding the Semi-Automatic Plastic Injection Machine

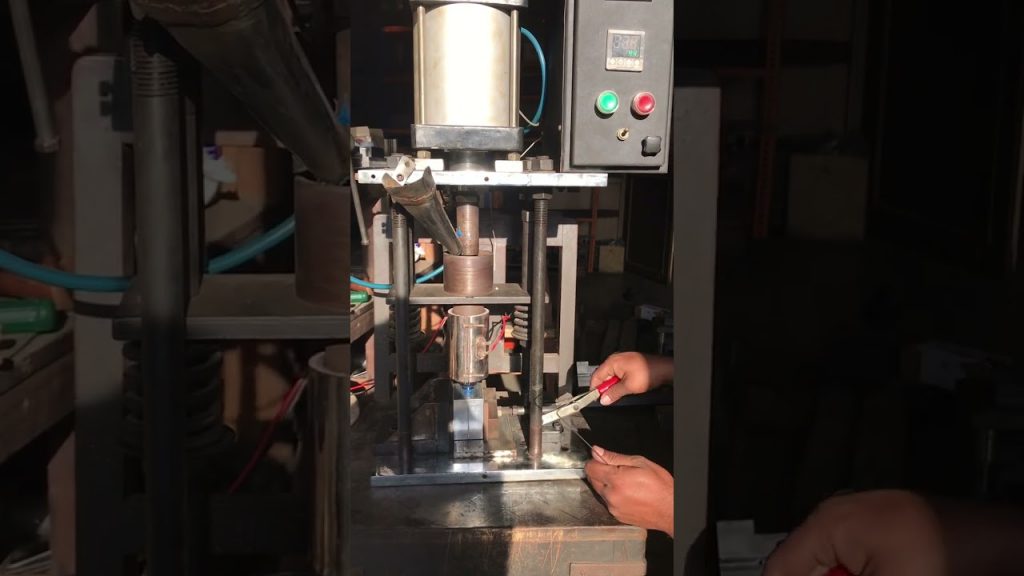

In this section, we will provide a comprehensive overview of the semi-automatic plastic injection machine. We’ll discuss its key features, such as its ability to automate certain aspects of the injection molding process while still allowing for manual control and adjustments. We’ll also explore the different components of the machine and how they work together to ensure precise and consistent plastic injection.

Section 2: The Benefits of Using a Semi-Automatic Plastic Injection Machine

In this section, we’ll highlight the numerous advantages of incorporating a semi-automatic plastic injection machine into your production line. From increased productivity and reduced labor costs to improved product quality and versatility, this machine offers a range of benefits that can give your business a competitive edge.

Section 3: Case Study: Real-Life Success Stories

To further illustrate the impact of the semi-automatic plastic injection machine, we’ll present a case study showcasing how a company successfully integrated this machine into their manufacturing process. We’ll delve into specific details, such as the challenges they faced, the solutions provided by the machine, and the overall positive outcomes they achieved.

Section 4: The Future of Plastic Injection Molding: Semi-Automatic Pneumatic Injection Molding Machine

In this section, we’ll discuss the advancements in technology that have led to the development of semi-automatic pneumatic injection molding machines. We’ll explore how these machines utilize pneumatic systems to enhance the efficiency and precision of the plastic injection process. By embracing this cutting-edge technology, manufacturers can further optimize their production and stay ahead of the competition.

Section 5: How to Choose the Right Semi-Automatic Plastic Injection Machine

In this section, we’ll provide valuable insights on selecting the most suitable semi-automatic plastic injection machine for your specific needs. We’ll discuss factors such as production volume, material compatibility, and budget considerations. By understanding these key factors, you can make an informed decision and invest in a machine that will deliver optimal results for your business.

Conclusion:

In conclusion, a semi-automatic plastic injection machine is a game-changer for any business involved in plastic injection molding. Its ability to automate certain processes while still allowing for manual control provides the perfect balance of efficiency and flexibility. By adopting this innovative technology, you can improve your production line, reduce costs, and ultimately achieve greater success in the competitive manufacturing industry.

Check out the YouTube video for a visual demonstration of the semi-automatic plastic injection machine in action. Don’t miss out on this opportunity to enhance your plastic injection molding process and take your business to new heights!

Check the coil packing solution with a leading manufacturer for a professional solution. Find out more here: [Insert appropriate website or contact information] Plastic Injection Machine

“Efficient and User-Friendly Injection Molding Machines for Plastic Manufacturing”