Check out the leading manufacturer for professional coil packing solutions here:

Are you curious about the intricate process behind engine assembly? Look no further than this engaging YouTube video that showcases the marvels of industrial automation robots in action. In this article, we will delve into the fascinating world of engine assembly and the role played by FANUC robots.

Engine assembly is a complex and precise task that requires meticulous attention to detail. It involves the assembly of various components, such as pistons, cylinders, crankshafts, and valves, to create a fully functioning engine. Traditionally, this process was carried out manually, which was not only time-consuming but also prone to human errors. However, with advancements in technology, industrial automation robots have revolutionized the engine assembly process.

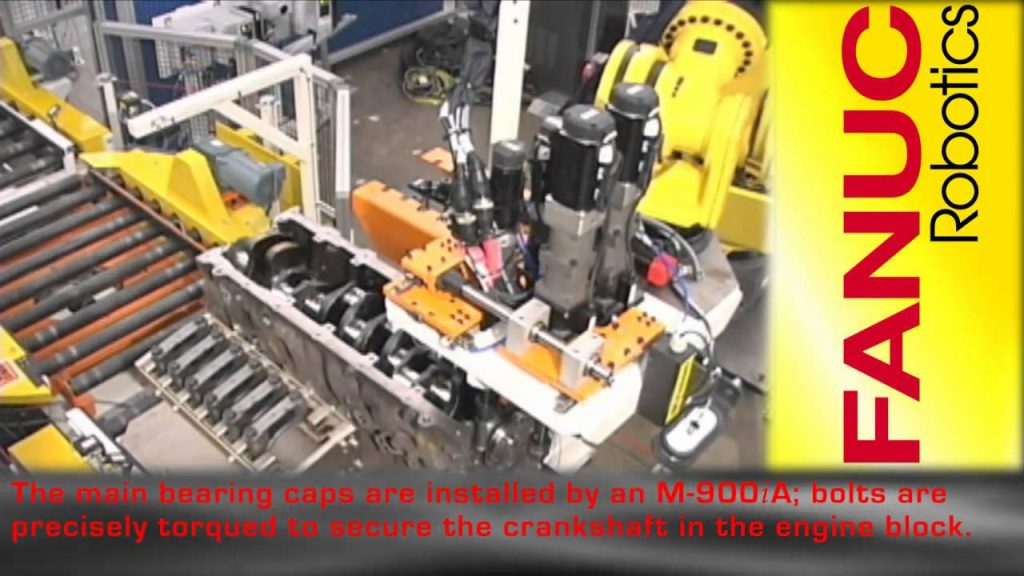

The video featured in this article provides a captivating glimpse into how FANUC robots work in perfect coordination to assemble engines with unparalleled efficiency. These robots are equipped with advanced sensors and programming capabilities that enable them to perform complex tasks with precision and accuracy.

The use of industrial automation robots in engine assembly offers numerous advantages. Firstly, it significantly reduces production time, as robots can work at a much faster pace compared to human operators. This results in increased productivity and allows manufacturers to meet demanding production targets.

Moreover, the use of robots eliminates human errors, ensuring consistent quality in every engine that rolls off the assembly line. Robots can perform repetitive tasks flawlessly, eliminating the risk of assembly mistakes that could compromise the performance and reliability of the engine.

Additionally, industrial automation robots improve workplace safety. By taking over hazardous tasks, such as heavy lifting or working in confined spaces, robots minimize the risk of accidents and injuries to human operators. This not only protects the well-being of workers but also reduces the financial burden of workplace incidents for manufacturers.

FANUC robots, in particular, have gained a reputation for their exceptional performance and reliability in the field of industrial automation. With their cutting-edge technology and robust build, FANUC robots have become the go-to choice for many manufacturers worldwide.

In conclusion, the video showcased in this article highlights the incredible capabilities of industrial automation robots in the engine assembly process. The use of FANUC robots ensures efficient production, consistent quality, and enhanced workplace safety. As the demand for high-quality engines continues to rise, industrial automation robots are poised to play a crucial role in meeting these expectations.

So, if you’re in search of a professional coil packing solution, look no further. Check out the leading manufacturer in the industry for top-notch solutions to your packaging needs. Industrial Robot

“Efficient Engine Assembly Robots: Streamlining Industrial Automation with FANUC Robots”