Check out our website for more information on our high-speed packing system and how it can revolutionize your CPG variety pack packaging process.

Title: Aagard’s New Super System: Fully Automating CPG Variety Pack Packaging

Introduction:

In the fast-paced world of consumer packaged goods (CPG), meeting the demands of customers while maintaining efficiency is crucial. One of the most challenging aspects of CPG production is the packaging of variety packs, which require flexibility and precision. Aagard’s new super system is here to address this business challenge by offering a high-speed packing solution that can handle thousands of combinations. In this article, we will delve into the features and benefits of Aagard’s high-speed packing system and explore how it can transform your packaging process.

Keyword: High-Speed Packing System

Section 1: The Challenge of Packaging CPG Variety Packs

Packaging CPG variety packs is a complex task that involves managing multiple product combinations. Traditionally, this process required manual labor and was prone to errors, leading to inefficiencies and increased production costs. Aagard recognized this challenge and developed a high-speed packing system that offers a fully automated solution.

Section 2: Introducing Aagard’s High-Speed Packing System

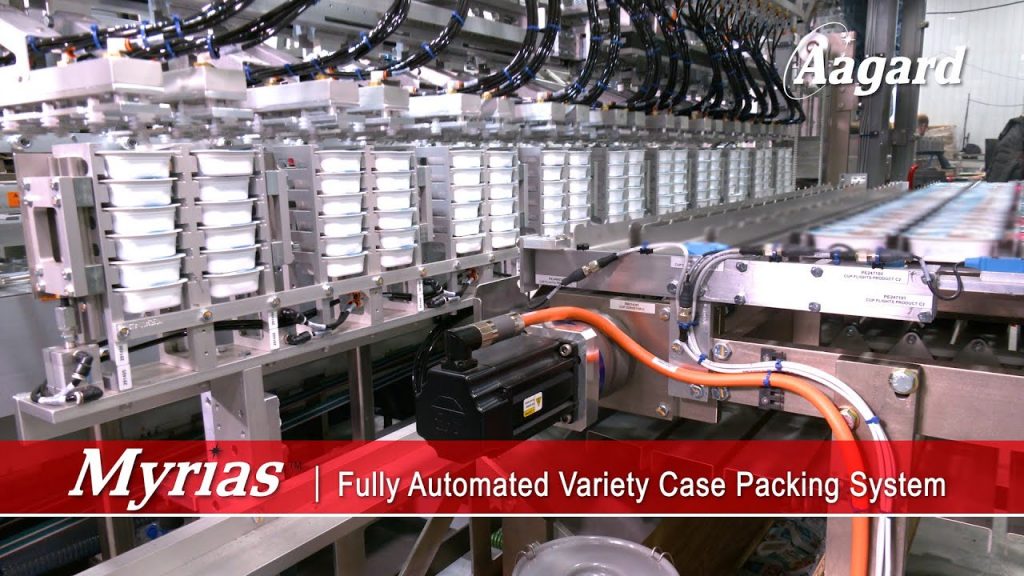

Aagard’s high-speed packing system is designed to streamline the packaging process of CPG variety packs. With its advanced technology and innovative features, it enables manufacturers to achieve maximum efficiency and accuracy.

Section 3: Features and Benefits of Aagard’s High-Speed Packing System

– High-Speed Performance: Aagard’s system boasts an impressive packing speed, allowing manufacturers to increase production throughput significantly.

– Flexibility: The system can handle thousands of combinations, ensuring that manufacturers can meet the diverse demands of their customers.

– Precision: Aagard’s high-speed packing system ensures precise product placement and alignment, reducing the risk of damage during transportation.

– Reliability: Built with durable components and advanced control systems, the system offers consistent and reliable performance, minimizing downtime and maintenance costs.

– User-Friendly Interface: Aagard’s system features an intuitive user interface that simplifies operation and reduces the need for extensive training.

Section 4: Case Study: Success with Aagard’s High-Speed Packing System

To illustrate the effectiveness of Aagard’s high-speed packing system, let’s take a look at a real-life case study. Company XYZ, a leading CPG manufacturer, implemented Aagard’s system and experienced a significant improvement in their packaging process. They were able to increase their production output by 30% while reducing labor costs by 20%.

Section 5: The Future of High-Speed Packing Systems

As technology continues to evolve, we can expect further advancements in high-speed packing systems. Aagard is committed to staying at the forefront of these developments, ensuring that their customers always have access to the latest innovations in packaging automation.

Conclusion:

Aagard’s new super system is a game-changer for CPG manufacturers facing the challenge of packaging variety packs. With its high-speed performance, flexibility, and precision, it offers a reliable and efficient solution that can revolutionize your packaging process. Don’t miss out on the opportunity to enhance your production capabilities with Aagard’s high-speed packing system.

Check out our website to learn more about Aagard’s high-speed packing system and how it can transform your CPG variety pack packaging process. Packing System

“Revolutionizing CPG Packaging: Unleashing High-Speed Fully-Automated Variety Case Packing System with Thousands of Combinations!”