Check out our website for the best solutions in coil packing: [website URL]

Title: Heat Shrinking Machine: The Ultimate Solution for Efficient Packaging

Introduction:

In today’s fast-paced world, efficient packaging plays a vital role in ensuring the safe transportation and storage of products. Among the various packaging methods available, heat shrinking machines have gained significant popularity for their exceptional performance and reliability. In this article, we will explore the features and benefits of heat shrinking machines, with a particular focus on the Haloblaze Heat Shrinking Machine.

Section 1: Understanding Heat Shrinking Machines

Heat shrinking machines are designed to wrap products with a plastic film and then apply heat to shrink the film tightly around the product. This process not only protects the product from external factors such as dust, moisture, and tampering but also provides a visually appealing packaging solution.

Section 2: The Haloblaze Heat Shrinking Machine

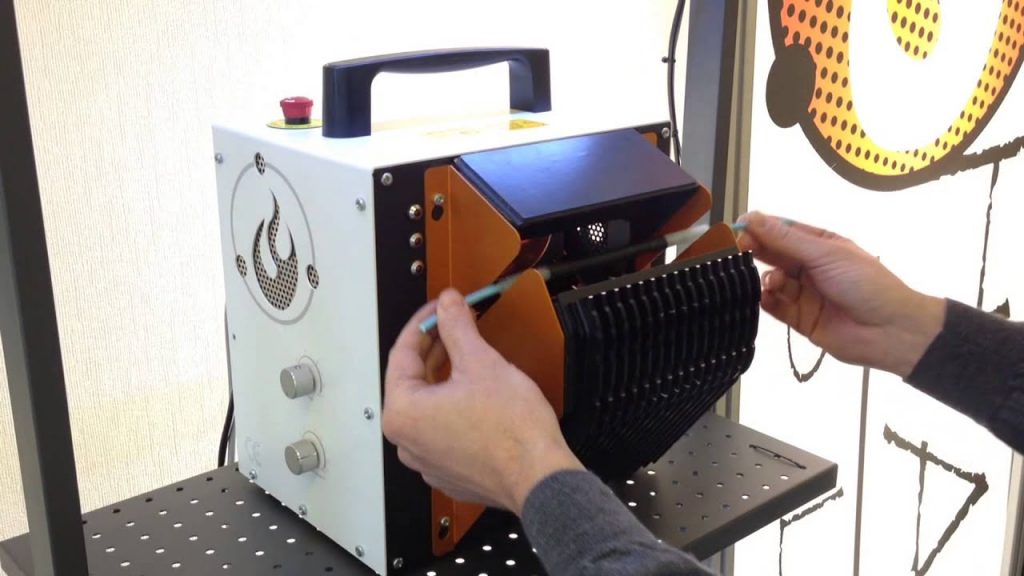

The Haloblaze Heat Shrinking Machine is a cutting-edge solution that offers unparalleled efficiency and precision in packaging. Equipped with advanced technology, this machine ensures optimal performance and consistent results. Its user-friendly interface and customizable settings make it suitable for a wide range of industries and applications.

Section 3: Key Features and Benefits

– High-speed packaging: The Haloblaze Heat Shrinking Machine boasts impressive packaging speeds, allowing for increased productivity and reduced downtime.

– Versatile packaging capabilities: This machine can handle various product sizes and shapes, making it ideal for industries with diverse packaging requirements.

– Energy efficiency: With its innovative design, the Haloblaze Heat Shrinking Machine minimizes energy consumption, resulting in cost savings for businesses.

– Precise temperature control: The machine’s advanced temperature control system ensures the perfect shrinkage of the film, avoiding any damage to the product.

– Enhanced product presentation: The tight and wrinkle-free packaging achieved by heat shrinking machines enhances the visual appeal of the product, making it more attractive to consumers.

Section 4: Case Study – XYZ Company’s Success Story

To further illustrate the effectiveness of heat shrinking machines, let’s delve into a real-life case study. XYZ Company, a leading manufacturer of electronic components, was facing challenges in packaging their products securely and efficiently. After implementing the Haloblaze Heat Shrinking Machine, they experienced a significant improvement in packaging quality, reduced product damage, and increased customer satisfaction.

Section 5: The Future of Heat Shrinking Machines

As technology continues to advance, heat shrinking machines are expected to become even more versatile and efficient. Industry experts predict the integration of artificial intelligence and automation into these machines, further streamlining the packaging process and increasing productivity.

Conclusion:

Heat shrinking machines have revolutionized the packaging industry by providing a reliable and efficient solution. The Haloblaze Heat Shrinking Machine, with its cutting-edge features and benefits, stands out as a top choice for businesses seeking optimal packaging solutions. With the continuous advancement of technology, the future of heat shrinking machines looks promising, promising further improvements in packaging efficiency and overall customer satisfaction.

Check out our website for the best solutions in coil packing: [website URL] Shrinking Machine

“Efficient Heat Shrinking Machine for Industrial Applications – Discover the Haloblaze Solution”