Title: “Efficient and Reliable Automatic Bagging Packing Line and Foam-in-bag Packing Machine – A Comprehensive Overview”

Description:

Introduction:

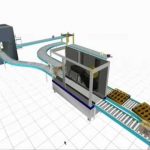

Welcome to our video showcasing the Automatic Bagging Packing Line and Automatic Instapak Foam-in-bag Packing Machine. In this video, we provide a detailed overview of these innovative packaging solutions offered by Yongjia Polyurethane CO.,LTD, a renowned Polyurethane PU foam machinery manufacturer in the industry.

Video Content:

Our video dives into the key features and benefits of the Automatic Bagging Packing Line and Automatic Instapak Foam-in-bag Packing Machine. We highlight their exceptional performance, efficiency, and reliability, making them indispensable assets for companies in need of high-quality packaging solutions.

The Automatic Bagging Packing Line offers seamless automation, streamlining the packaging process and increasing productivity. It ensures precise bagging, sealing, and labeling, eliminating human errors and reducing packaging time. With its user-friendly interface and customizable settings, this packing line is adaptable to various products and packaging requirements.

The Automatic Instapak Foam-in-bag Packing Machine takes packaging to the next level. By utilizing the innovative Instapak foam technology, it creates custom-fit protective foam cushions that securely hold products during transportation. This machine optimizes packaging space, reduces material waste, and provides exceptional protection against impact, vibration, and moisture.

Operation Steps:

In this video, we demonstrate the step-by-step operation of both machines. From initial setup to final packaging, we guide you through the entire process, ensuring a clear understanding of how these machines can revolutionize your packaging operations.

Call to Action:

If you found this video informative and valuable, we encourage you to like, subscribe, and share it with others who might benefit from this cutting-edge packaging technology. Stay updated with our latest videos by subscribing to our channel.

Additional Tags and Keywords:

Automatic Bagging Packing Line, Automatic Instapak Foam-in-bag Packing Machine, Polyurethane PU foam machinery, packaging solutions, automation, productivity, efficiency, reliable, high-quality packaging, user-friendly interface, customizable settings, Instapak foam technology, protective foam cushions, impact protection, vibration protection, moisture protection.

Hashtags:

#AutomaticPackagingSolutions #InstapakTechnology #PolyurethaneMachinery #EfficientPackaging #ReliablePackaging

Title: Automatic Instapak Foam-in-Bag Packing Machine: Ensuring Superior Packaging Efficiency

Introduction:

The Automatic Instapak Foam-in-Bag Packing Machine is a cutting-edge solution designed to revolutionize packaging processes. This advanced machine offers numerous advantages, including enhanced speed, efficiency, and reliability. To maximize its potential, a well-optimized tilter is crucial. This tilter aims to enhance the machine’s performance by ensuring precise foam distribution and consistent packaging quality. Let’s explore the key features and benefits of this tilter for the Automatic Instapak Foam-in-Bag Packing Machine.

Key Features:

1. Precision Foam Control: The tilter optimizes foam distribution within the bag, ensuring uniform and consistent foam coverage. This feature guarantees that the product is securely protected during transit.

2. Adjustable Tilt Angle: The tilter allows operators to adjust the tilt angle as per specific packaging requirements. This flexibility ensures compatibility with a wide range of product sizes and shapes, accommodating diverse packaging needs.

3. Quick and Easy Setup: The tilter is designed for convenient installation and setup, minimizing downtime and allowing businesses to maintain high productivity levels. Its user-friendly interface ensures effortless configuration and operation.

4. Remote Control Capability: The tilter can be operated remotely, allowing operators to control the machine from a safe distance. This feature enhances workplace safety, particularly when handling large and heavy products.

5. Compatibility with Multiple Instapak Models: The tilter is compatible with various models of the Automatic Instapak Foam-in-Bag Packing Machine, ensuring seamless integration into existing packaging systems. This compatibility extends its usability for businesses of various sizes and industries.

Benefits:

1. Enhanced Packaging Efficiency: The tilter optimizes foam distribution, reducing wastage and minimizing the need for rework, thus maximizing packaging productivity. It ensures efficient foam-in-bag packaging, saving time and resources.

2. Improved Product Protection: With precise foam control, the tilter ensures that products are adequately cushioned and protected throughout shipping and handling. This feature reduces the risk of product damage, enhancing customer satisfaction.

3. Increased Versatility: The adjustable tilt angle feature allows for packaging a wide range of product sizes and shapes, making it a versatile choice for businesses with diverse packaging needs.

4. Time and Cost Savings: By streamlining the packaging process, the tilter helps businesses save valuable time and reduce operational costs. Its remote control capability also enhances overall efficiency and employee safety.

Conclusion:

The tilter for the Automatic Instapak Foam-in-Bag Packing Machine is an indispensable accessory that enhances packaging efficiency, ensures optimal foam distribution, and provides versatile packaging capabilities. With its precision foam control, adjustable tilt angle, and user-friendly operation, this tilter is a valuable investment for businesses seeking to streamline their packaging processes and deliver superior product protection. coil packing line

#Automatic #Instapak #Foaminbag #Packing #Machine