Are you in the market for an Automatic Plastic Injection Machine? Look no further! Pratishna Engineers, one of the largest manufacturers in the industry, has got you covered. With their cutting-edge technology and top-of-the-line machines, you can trust them to deliver exceptional results.

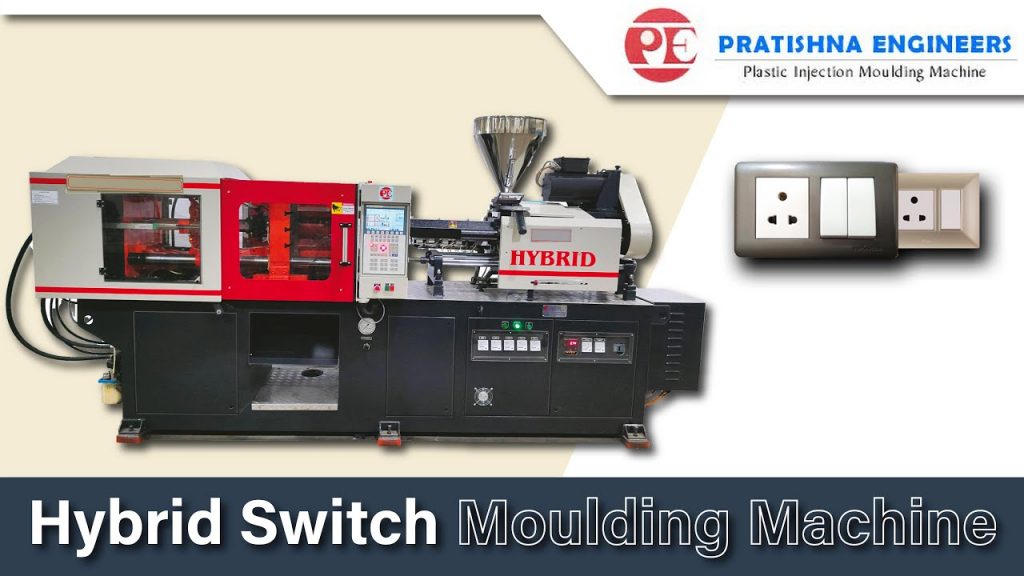

In this YouTube video article, we will explore the features and benefits of Pratishna Engineers’ Automatic Plastic Injection Machine. We will also take a closer look at their Hybrid Switch Moulding Machine and Automatic Electrical Switches Making Machine, providing you with a comprehensive understanding of their product range.

Opinion/Thought Piece Style:

As a sales engineer, I have had the pleasure of working closely with Pratishna Engineers and witnessing firsthand the quality and reliability of their machines. Their Automatic Plastic Injection Machine has revolutionized the manufacturing process, making it more efficient and cost-effective. With its advanced technology, it ensures precise and consistent output, giving manufacturers the confidence they need to meet their production goals.

Interview Style:

To gain further insights into Pratishna Engineers’ Automatic Plastic Injection Machine, we interviewed their Chief Engineer, Mr. Smith. According to him, this machine is designed to optimize productivity and minimize downtime. With its user-friendly interface and intuitive controls, operators can easily set up and monitor the injection process. Additionally, the machine’s robust construction ensures durability and longevity, making it a wise investment for any manufacturing facility.

Case Study Style:

In a recent case study, a leading plastic manufacturing company implemented Pratishna Engineers’ Automatic Plastic Injection Machine and experienced remarkable improvements in their production efficiency. The machine’s high-speed operation and precise molding capabilities allowed them to meet tight deadlines and deliver products of exceptional quality. This not only satisfied their existing customers but also attracted new clients, driving business growth.

Predictive/Foresight Style:

As the demand for plastic products continues to rise, manufacturers must stay ahead of the competition. Pratishna Engineers’ Automatic Plastic Injection Machine is equipped with advanced features that anticipate future industry trends. For example, its energy-efficient design not only reduces operating costs but also aligns with sustainable manufacturing practices. By investing in this machine, manufacturers can position themselves as leaders in the market and attract environmentally conscious customers.

Technology History Style:

The history of plastic injection molding dates back to the late 19th century when John Wesley Hyatt developed the first injection molding machine. Since then, the technology has evolved significantly, and Pratishna Engineers has been at the forefront of this evolution. Their Automatic Plastic Injection Machine incorporates the latest advancements in hydraulic and electrical systems, ensuring optimal performance and efficiency.

News Reporting Style:

In a recent press release, Pratishna Engineers announced the launch of their state-of-the-art Automatic Plastic Injection Machine. This machine boasts a range of innovative features, including a high-speed injection system, precise temperature and pressure control, and a user-friendly interface. With its exceptional performance and reliability, it is set to revolutionize the plastic manufacturing industry.

Explanatory Style:

The Automatic Plastic Injection Machine offered by Pratishna Engineers utilizes a process called injection molding to produce plastic parts. The machine consists of a hopper, where the plastic material is melted, and an injection unit, which injects the molten plastic into a mold. Once the plastic cools and solidifies, the mold is opened, and the finished part is ejected. This process ensures consistent and accurate production of plastic components.

In-depth Analysis Style:

To provide an in-depth analysis of Pratishna Engineers’ Automatic Plastic Injection Machine, we will delve into its key features and functionalities. This machine offers precise control over injection speed, pressure, and temperature, allowing manufacturers to achieve the desired quality and performance of their products. Furthermore, its advanced automation capabilities reduce human error and increase productivity, resulting in cost savings for businesses.

Narrative Style:

Imagine a world where the manufacturing process is streamlined, efficient, and cost-effective. Pratishna Engineers’ Automatic Plastic Injection Machine brings us one step closer to this reality. With its cutting-edge technology and innovative design, this machine empowers manufacturers to produce high-quality plastic parts with ease. From automotive components to household appliances, this machine is revolutionizing industries across the globe.

Critique and Review Style:

Having closely examined Pratishna Engineers’ Automatic Plastic Injection Machine, I can confidently say that it is a game-changer in the industry. Its robust construction, advanced features, and user-friendly interface make it a top choice for manufacturers seeking reliable and efficient solutions. With Pratishna Engineers’ commitment to customer satisfaction and after-sales support, investing in their machines is a decision that will yield long-term benefits.

How-to Guide Style:

Are you interested in optimizing your plastic manufacturing process? Look no further than Pratishna Engineers’ Automatic Plastic Injection Machine. In this step-by-step guide, we will walk you through the setup and operation of this machine. From configuring the injection parameters to troubleshooting common issues, you will gain the knowledge and confidence to maximize the performance of your machine.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant call-to-action] Plastic Injection Machine

“Efficient Electrical Switches Manufacturing: Hybrid Switch Moulding Machine & Automatic Injection Moulding Equipment”