Check out the leading manufacturer for professional coil packing solutions here:

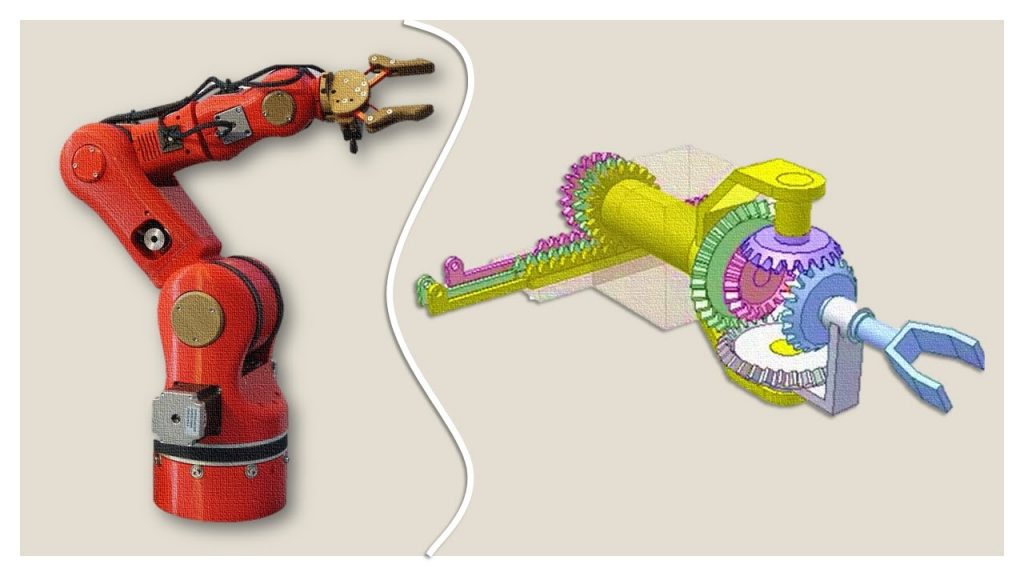

In this YouTube video, we will delve into the fascinating world of Spherical Geared Robotic-Arm Mechanisms. Specifically, we will explore the utilization of rack and pinion gear mechanisms to enable rotation in conjunction with an Industrial Robot Arm. This article aims to provide an in-depth analysis of the Industrial Robot Arm and Geared Spherical Robotic Arm Mechanism, referencing the work of AkMiNuL in Mechanical Design.

Introduction:

Industrial Robot Arms have revolutionized various industries by automating tasks traditionally performed by humans. These versatile machines are capable of executing precise movements and repetitive actions, enhancing efficiency and productivity. To further optimize their functionalities, engineers have developed innovative mechanisms, such as the Spherical Geared Robotic-Arm Mechanism, to enhance their capabilities.

Understanding the Spherical Geared Robotic-Arm Mechanism:

The Spherical Geared Robotic-Arm Mechanism involves the integration of a rack and pinion gear mechanism with an Industrial Robot Arm. This combination enables rotational movements, expanding the range of actions the robot can perform. The rack and pinion gear system consists of a toothed rack and a pinion gear, where the rotational motion of the pinion gear transfers to the linear motion of the rack. By incorporating this mechanism into an Industrial Robot Arm, engineers can achieve precise and controlled rotations, allowing for enhanced versatility and flexibility in various applications.

Benefits and Applications:

The integration of the Spherical Geared Robotic-Arm Mechanism brings several benefits to industrial processes. Firstly, it enables the robot arm to reach and manipulate objects from different angles, expanding its range of motion. This is particularly useful in applications such as assembly lines, where parts need to be accessed and positioned accurately. Additionally, the mechanism facilitates smooth and precise rotations, ensuring seamless movements and reducing the risk of errors or damages during operation.

The Spherical Geared Robotic-Arm Mechanism finds application in various industries. In manufacturing, it aids in tasks such as material handling, pick and place operations, and welding. The mechanism also plays a crucial role in the automotive industry, where it assists in assembly processes and painting applications. Furthermore, the integration of this mechanism in the medical field enables robotic arms to perform delicate surgeries with high precision and accuracy.

Case Study: GE’s Use of Spherical Geared Robotic-Arm Mechanism:

To illustrate the practical application of the Spherical Geared Robotic-Arm Mechanism, we will examine a case study involving General Electric (GE). GE utilizes this mechanism in their manufacturing processes to enhance efficiency and productivity. By incorporating this technology, GE’s Industrial Robot Arms can perform complex movements and tasks with precision, resulting in improved manufacturing output and reduced downtime.

Conclusion:

The Spherical Geared Robotic-Arm Mechanism is a remarkable innovation that enhances the capabilities of Industrial Robot Arms. By integrating rack and pinion gear mechanisms, engineers can achieve precise and controlled rotations, enabling robots to perform a wide range of tasks with enhanced versatility. Industries such as manufacturing, automotive, and healthcare greatly benefit from this mechanism, enhancing efficiency and precision in their respective processes.

Check out the leading manufacturer for professional coil packing solutions here:

Note: This article is based on the work and research of AkMiNuL in Mechanical Design. Industrial Robot

“Revolutionizing Industrial Robotics: Unveiling the Cutting-Edge Geared Spherical Robotic Arm Mechanism”