Title: Achieve Efficiency and Accuracy with the ALTECH Pharmaceutical Labeling Machine

Description:

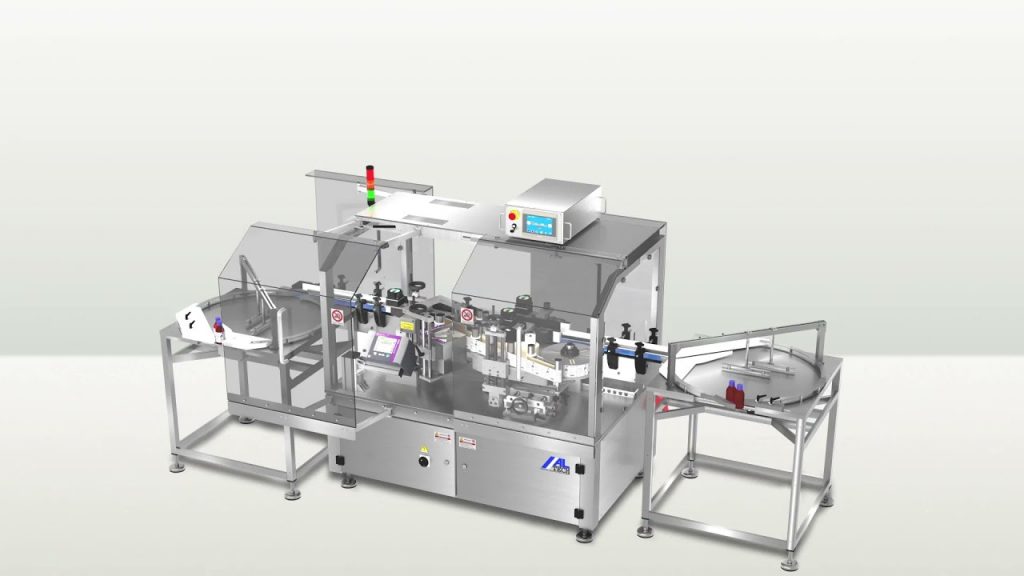

Welcome to our informative video showcasing the cutting-edge ALTECH Pharmaceutical Labeling Machine – ALPHARMA C. This advanced automatic labeling machine revolutionizes the pharmaceutical industry by offering precise and efficient wrap-around labeling solutions.

Heading 1: Introduction

In this video, we delve into the world of automatic labeling machines, specifically focusing on the ALTECH Pharmaceutical Labeling Machine – ALPHARMA C. Gain valuable insights into the technology behind this innovative machine and how it enhances the labeling process for pharmaceutical products.

Heading 2: Key Features and Benefits

Discover the exceptional features that set the ALTECH Pharmaceutical Labeling Machine – ALPHARMA C apart from its counterparts. From its unwavering accuracy to its seamless in-line wrap-around labeling capabilities, this machine ensures that pharmaceutical products are labeled correctly and efficiently. Experience reduced downtime and enhanced productivity with this state-of-the-art labeling solution.

Heading 3: Operation Steps

Learn about the step-by-step process of operating the ALTECH Pharmaceutical Labeling Machine – ALPHARMA C. From setting up the machine to adjusting label parameters and monitoring its performance, our video provides a comprehensive overview of how to optimize the machine for your labeling needs.

Heading 4: Key Highlights and Interesting Facts

Discover fascinating insights and interesting facts about the ALTECH Pharmaceutical Labeling Machine – ALPHARMA C. Learn about its ability to handle various types of packaging and labels, its user-friendly interface, and its contribution to improving overall labeling efficiency in the pharmaceutical industry.

Call to Action:

If you found our video informative and valuable, please don’t forget to like, subscribe, and share it with others who may benefit from this knowledge. Stay updated with the latest advancements in pharmaceutical labeling technology by joining our community.

Additional Tags and Keywords:

Automatic Labeling Machine, Pharmaceutical Labeling Machine, Wrap Around Labeling, ALTECH Pharmaceutical Labeling Machine, ALPHARMA C, in-line wrap-around labeling, labeling solutions, pharmaceutical industry, labeling process, efficiency, accuracy, advanced technology, productivity enhancement.

Hashtags:

#AutomaticLabelingMachine #PharmaceuticalLabeling #WrapAroundLabeling #ALTECHPharmaceuticalLabeling #ALPHARMAC #LabelingSolutions #PharmaceuticalIndustry #Efficiency #Accuracy #ProductivityEnhancement

Here’s a possible tilter for a Pharmaceutical Labeling Machine – Wrap Around Labeling:

1. Start by ensuring that the labeling machine is turned off and all power sources are disconnected to avoid any accidents during the tilter installation process.

2. Identify the area on the labeling machine where the tilter will be installed. It should be a flat and stable surface that can support the weight of the tilter.

3. Position the tilter in the desired location on the labeling machine. Mark the mounting holes on the machine using a marker or pencil.

4. Use appropriate tools to drill holes on the marked spots for the tilter mounting. Ensure that the holes are suitable for the size of the tilter’s mounting screws.

5. Insert the mounting screws through the holes on the tilter and align them with the drilled holes on the labeling machine. Secure the tilter using nuts or fasteners that came with the tilter.

6. Double-check the stability and alignment of the tilter. Make any necessary adjustments to ensure that it is securely attached to the labeling machine.

7. Once the tilter is securely mounted, connect the necessary cables or wires to the tilter according to the manufacturer’s instructions. This may include power cables, control cables, or communication cables.

8. Carefully route and organize the cables to prevent any interference with the labeling machine’s operation. Use cable ties or cable management systems if necessary.

9. Reconnect the power sources to the labeling machine and turn it on. Test the tilter’s functionality by operating the labeling machine and observing the tilting action.

10. Conduct thorough testing of the tilter’s performance to ensure that it aligns the labels accurately and consistently during the wrap-around labeling process.

11. Regularly inspect and maintain the tilter to ensure its proper functioning. Follow the manufacturer’s guidelines for maintenance and troubleshooting.

Note: It is crucial to consult the manufacturer’s instructions and guidelines specific to the labeling machine and tilter being used for accurate installation and operation.Labeling Machine

#Pharmaceutical #Labeling #Machine #Wrap #Labeling