Title: Unrivaled Precision and Efficiency: Explore the World of Labeling Machine Manufacturers and Semi-Automatic Labelling Machines

Description:

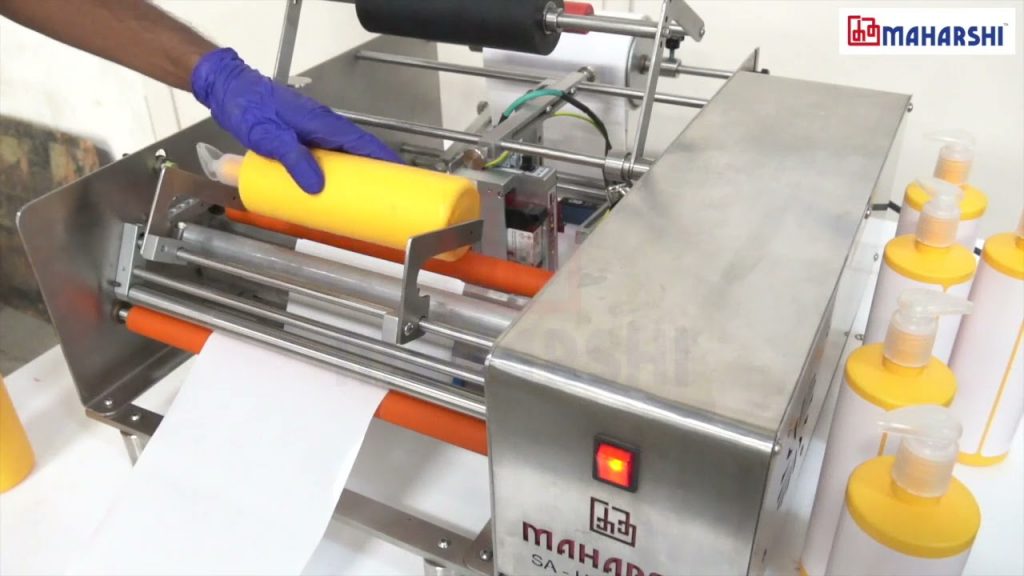

Welcome to our comprehensive guide on Labeling Machine Manufacturers, Semi-Automatic Labelling Machines, Bottle Labelling Machines, and Sticker Labelling Machines. In this video, we dive deep into the world of labeling machines, uncovering their robust design, unrivaled precision, and guaranteed label accuracy. If you’re curious to know how a semi-automatic labeling machine works, you’ve come to the right place!

Introduction:

In this video, we explore the fascinating world of Labeling Machine Manufacturers and their incredible range of Semi-Automatic Labelling Machines. From Bottle Labelling Machines to Sticker Labelling Machines, we take a closer look at their robust construction, unmatched precision, and their ability to ensure label accuracy with every application.

Video Content:

1. The Importance of Labeling Machines:

– Discover why labeling machines are crucial for various industries, ensuring efficiency and productivity.

– Explore the benefits of using labeling machines, such as improved product presentation and compliance with regulations.

2. Unraveling the Mystery: How a Semi-Automatic Labeling Machine Works:

– Step-by-step guide illustrating the operation of a semi-automatic labeling machine.

– Learn about the key components, including the labeling head, conveyor system, and control panel.

– Gain insights into the labeling process, from label detection to precise label placement.

3. Unmatched Precision and Accuracy:

– Understand how labeling machines guarantee label accuracy, minimizing errors and wastage.

– Learn about advanced features like label sensors and positioning systems, ensuring precise label application.

– Explore the benefits of automatic label adjustment, accommodating various container sizes and shapes.

4. Versatility and Adaptability of Bottle Labelling Machines:

– Discover the wide range of containers that can be labeled using bottle labelling machines.

– Learn about the flexibility of bottle labeling machines, accommodating different label materials and sizes.

– Explore the potential for customization, including options for front, back, and wrap-around labeling.

Call to Action:

If you found this video insightful and informative, please consider liking, subscribing, and sharing it with others who might benefit from this valuable knowledge. Stay updated with our latest videos on labeling machines and related topics.

Additional Tags and Keywords: labeling machines, semi-automatic labeling machine, bottle labeling machine, sticker labeling machine, label accuracy, labeling process, label placement, label sensors, positioning systems, automatic label adjustment, bottle labeling, container labeling.

Hashtags: #LabelingMachines #SemiAutomaticLabelling #BottleLabeling #StickerLabeling #LabelAccuracy #Precision

Here is a sample tilter for a Semi Automatic Labelling Machine, Bottle Labelling Machine, and Sticker Labelling Machine:

Title: Efficient and Versatile Tilter for Semi Automatic Labelling Machine, Bottle Labelling Machine, and Sticker Labelling Machine

Introduction:

In today’s fast-paced manufacturing industry, the demand for efficient and versatile labelling machines is increasing. To meet this demand, we present a tilter specifically designed for semi-automatic labelling machines, bottle labelling machines, and sticker labelling machines. This tilter aims to enhance the productivity and flexibility of these machines, ultimately improving the overall labelling process.

1. Enhanced Efficiency:

Our tilter is equipped with advanced technology that ensures a smooth and seamless tilting operation. It allows for precise positioning of the label roll, minimizing downtime caused by misalignment or jams. This enhanced efficiency leads to higher production rates and reduced labor costs.

2. Versatile Design:

The tilter is compatible with various types and sizes of labels, accommodating the diverse needs of different labelling machines. Whether it’s cylindrical bottles, flat surfaces, or irregularly shaped containers, our tilter can effortlessly handle them all. This versatility eliminates the need for multiple tilters for different machines, thereby optimizing space and cost-effectiveness.

3. Easy Integration:

Integrating our tilter with your existing labelling machines is a breeze. Its user-friendly interface allows for seamless connection and synchronization, ensuring a hassle-free operation. The tilter can be easily adjusted and customized to suit specific labelling requirements, making it a perfect fit for any production line.

4. Precision and Accuracy:

With our tilter’s precise control system, you can achieve accurate label placement with every application. The adjustable tilt angle ensures optimal label alignment, avoiding any inconsistencies or errors during the labelling process. This level of precision guarantees a professional and polished appearance for your products.

5. Durability and Reliability:

Our tilter is built to withstand the demands of continuous operation in industrial environments. Its robust construction and high-quality components ensure long-term reliability, reducing the risk of breakdowns and maintenance costs. This durability translates into uninterrupted production and enhanced customer satisfaction.

Conclusion:

In conclusion, our tilter for semi-automatic labelling machines, bottle labelling machines, and sticker labelling machines offers enhanced efficiency, versatility, easy integration, precision, and durability. By incorporating this tilter into your labelling process, you can streamline operations, increase productivity, and maintain a competitive edge in the market. Experience the benefits of our tilter and revolutionize your labelling capabilities.Labeling Machine

#Semi #Automatic #Labelling #Machine #Bottle #Labelling #Machine #Sticker #Labelling #Machine