Check out Geku Automation, the leading provider of robotic applications for various industrial purposes. With a wide range of cutting-edge solutions, Geku Automation is revolutionizing the way industries operate.

Industrial Robot Applications have become the backbone of modern manufacturing processes. They offer precision, speed, and efficiency that surpass human capabilities. Geku Automation understands the importance of these applications and provides a comprehensive range of solutions to meet the diverse needs of industries.

From assembly lines to packaging, Geku Automation offers a wide variety of robotic applications. Let’s dive into some of their most innovative and practical solutions:

1. Assembly Line Automation:

Geku Automation’s robotic applications are designed to streamline assembly line processes. These robots are equipped with advanced sensors and programming to ensure precise and error-free assembly. By automating this process, industries can significantly increase productivity and reduce costs.

2. Packaging and Palletizing:

Efficient packaging and palletizing are crucial for industries dealing with high volumes of products. Geku Automation offers robotic solutions that can handle various packaging materials and sizes. These robots can quickly and accurately pack products, ensuring consistency and minimizing errors.

3. Material Handling:

Material handling is a labor-intensive task that can be easily automated with industrial robots. Geku Automation provides solutions that can handle heavy loads, optimize warehouse space, and reduce the risk of injuries. These robots can efficiently transfer materials from one location to another, improving overall operational efficiency.

4. Quality Control and Inspection:

Ensuring the quality of products is essential for any industry. Geku Automation’s robotic applications include advanced vision systems that can perform precise inspections and quality control checks. These robots can detect defects, measure dimensions, and verify product integrity, ensuring only the highest quality products reach the market.

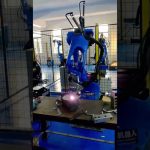

5. Welding and Cutting:

Geku Automation’s robotic welding and cutting applications offer superior precision and efficiency. These robots can perform complex welding operations with minimal human intervention, reducing the risk of errors and improving overall productivity. With their advanced programming capabilities, these robots can adapt to various welding and cutting requirements.

6. Collaborative Robots:

Collaborative robots, also known as cobots, are designed to work alongside humans, enhancing productivity and safety. Geku Automation provides cobots that can perform repetitive tasks, assist in material handling, and collaborate with human workers. These robots are easy to program and can be quickly integrated into existing workflows.

In conclusion, Geku Automation is at the forefront of providing innovative robotic applications across various industries. Their solutions offer increased productivity, improved efficiency, and enhanced safety. By embracing Industrial Robot Applications, industries can stay ahead in the rapidly evolving market.

Check out Geku Automation’s website for more information and discover how their robotic applications can transform your industry. Industrial Robot

“Revolutionizing the Future: Unleashing the Potential of Robotic Applications in Industrial Environments”