Check out our website for more information on our top-of-the-line coil packing solutions.”

Plumbing Materials: Exploring the Production Process of PVC Joint Connectors and Pipes

Introduction:

Plumbing is an essential aspect of any construction project, whether it’s for residential, commercial, or industrial purposes. One crucial component of plumbing systems is PVC joint connectors and pipes. In this YouTube video, we will delve into the making of PVC joint connectors and explore the production process of PVC pipes.

Style: Explanatory Style

Structure: Narrative Structure

Video Article:

Title: Plumbing Materials: Exploring the Production Process of PVC Joint Connectors and Pipes

Introduction:

Hello, everyone, and welcome back to our channel! Today, we are going to take a deep dive into the fascinating world of plumbing materials. Specifically, we will shed light on the production process of PVC joint connectors and pipes.

If you’ve ever wondered how these essential components are made, stay tuned, as we have some exciting insights to share with you.

Section 1: Understanding PVC Joint Connectors

PVC joint connectors play a crucial role in plumbing systems, as they provide a secure and leak-proof connection between pipes. These connectors are made from PVC (Polyvinyl Chloride), a versatile and durable plastic material known for its excellent chemical resistance and performance.

The Making of PVC Joint Connectors:

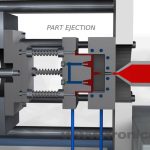

The production process of PVC joint connectors involves the use of advanced plastic injection molding machines. These machines are designed to inject molten PVC material into molds, resulting in the desired shape and form of the joint connector.

Section 2: The Production Process of PVC Pipes

PVC pipes are widely used in various plumbing applications due to their exceptional durability, corrosion resistance, and affordability. Let’s explore how these pipes are manufactured.

Step 1: Raw Material Preparation

The production of PVC pipes starts with the preparation of raw materials. PVC resin, along with additives such as stabilizers, plasticizers, and pigments, is mixed in specific proportions to achieve the desired characteristics of the pipes.

Step 2: Plastic Injection Molding

Once the raw materials are prepared, they are fed into a plastic injection molding machine. This machine heats the PVC material to a molten state and injects it into a specially designed mold cavity. The mold determines the shape and size of the PVC pipe.

Step 3: Cooling and Solidification

After injection, the molten PVC material rapidly cools and solidifies within the mold cavity. This step ensures that the pipe maintains its shape and structure.

Step 4: Cutting and Finishing

Once the PVC pipe has solidified, it is ejected from the mold and undergoes further processing. This includes cutting the pipe to the desired length and applying any necessary finishing touches, such as chamfering or bevelling the edges.

Conclusion:

In this video, we have explored the production process of PVC joint connectors and pipes. From the injection molding of PVC joint connectors to the preparation and molding of PVC pipes, we have gained valuable insights into the intricate manufacturing processes behind these essential plumbing materials.

Plastic Injection Machine Price:

If you are interested in venturing into the production of plumbing materials or seeking to upgrade your existing manufacturing setup, it is crucial to consider the cost of plastic injection machines. These machines play a vital role in the production process and can significantly impact the quality and efficiency of your operations.

To find the best plastic injection machine price and reliable machinery suppliers, we recommend reaching out to industry-leading manufacturers who specialize in providing high-quality equipment and solutions for the plumbing industry.

Check the coil packing solution with leading manufacturers for the professional solution just here:

Remember to check out our website for more information on our top-of-the-line coil packing solutions.

Thank you for watching, and we hope you found this video informative. Don’t forget to like, share, and subscribe to our channel for more exciting content on plumbing materials and manufacturing processes.

Until next time, take care and stay tuned for more industry insights! Plastic Injection Machine

“Revolutionizing Plastic Injection Molding: Uncover Billionaire Business Ideas and Discover Affordable Machinery Prices!”