Industrial robots have revolutionized the manufacturing industry, making production processes more efficient and cost-effective. These advanced machines are capable of performing complex tasks with precision and speed, and they have become an essential component in factories worldwide. However, the price of industrial robots can vary significantly depending on various factors. In this article, we will explore the factors that influence industrial robot prices and discuss the assembly process of a 3D printed robotic arm.

Industrial Robot Price: Factors to Consider

When it comes to purchasing an industrial robot, one of the primary considerations is the price. The cost of an industrial robot can range from a few thousand dollars to several hundred thousand dollars. Several factors influence the price of an industrial robot, including:

1. Type of Robot: There are various types of industrial robots available in the market, such as articulating robots, Cartesian robots, SCARA robots, and delta robots. Each type has its own set of capabilities and specifications, which can affect the price.

2. Payload Capacity: The payload capacity refers to the maximum weight that a robot can handle. Robots with higher payload capacities often come with a higher price tag, as they require more powerful motors and sturdier construction to handle heavy loads.

3. Reach and Range: The reach and range of a robot determine its workspace. Robots with a longer reach and wider range can cover a larger area, making them suitable for applications that require a larger workspace. However, robots with extended reach and range tend to be more expensive.

4. Accuracy and Precision: Industrial robots are known for their high precision and accuracy. Robots with higher precision levels often come with a higher price, as they require advanced sensors and control systems to achieve precise movements.

5. Additional Features: Some industrial robots come with additional features like built-in vision systems, force sensing capabilities, and advanced programming interfaces. These features can enhance the robot’s functionality but also contribute to the overall cost.

Assembly of a 3D Printed Robotic Arm

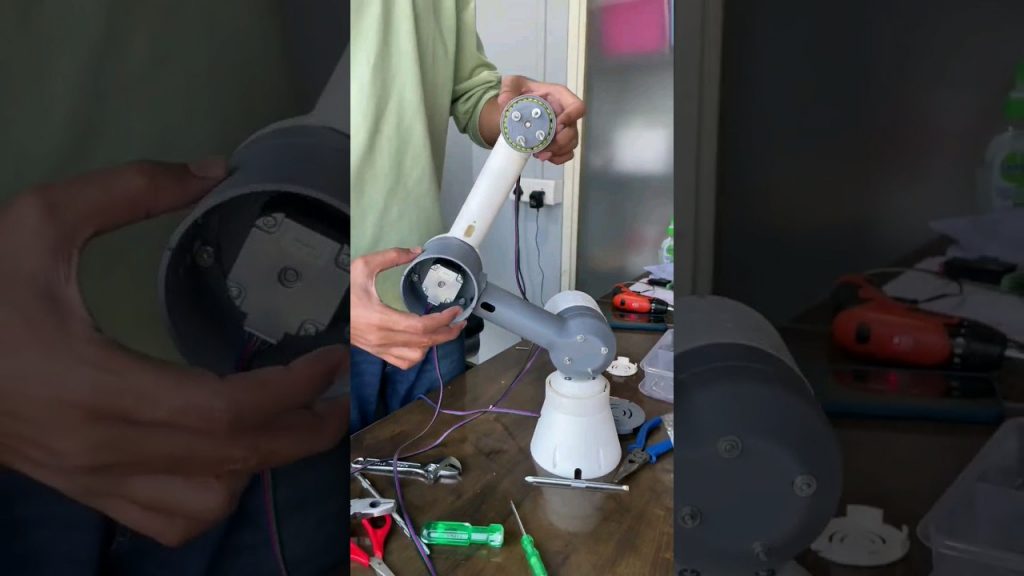

One exciting development in the field of industrial robotics is the use of 3D printing technology to manufacture robotic arms. 3D printing allows for the creation of complex and intricate designs with ease, making it an ideal manufacturing method for robotic components.

The assembly process of a 3D printed robotic arm typically involves the following steps:

1. Design: The first step in the assembly process is the design of the robotic arm. Engineers use computer-aided design (CAD) software to create a digital model of the arm, taking into account factors like size, weight, and functionality.

2. 3D Printing: Once the design is finalized, the robotic arm components are 3D printed using specialized printers that can create parts with high precision and accuracy. The 3D printing process involves layer-by-layer deposition of material, usually plastic or metal, to build the desired shape.

3. Post-Processing: After the components are 3D printed, they undergo post-processing to remove any support structures and smooth out rough edges. This step ensures that the parts are ready for assembly and function properly.

4. Assembly: The 3D printed components are then assembled to create the robotic arm. This process involves attaching the various parts together using screws, bolts, or other fastening mechanisms. The assembly process may also include the installation of motors, sensors, and other electronic components.

5. Testing and Calibration: Once the robotic arm is assembled, it undergoes rigorous testing and calibration to ensure that it functions correctly. This involves checking the range of motion, accuracy, and precision of the arm, as well as calibrating the control systems.

Conclusion

Industrial robots have become an indispensable part of modern manufacturing processes, streamlining production and improving efficiency. The price of industrial robots can vary significantly depending on factors such as type, payload capacity, reach, accuracy, and additional features. Additionally, the use of 3D printing technology in the assembly of robotic arms has opened up new possibilities for design and manufacturing. By leveraging the benefits of 3D printing, engineers can create robotic arms that are not only cost-effective but also highly customizable to meet specific industrial requirements.

Check the coil packing solution with a leading manufacturer for a professional solution by visiting their website today. Industrial Robot

“Efficient Robotic Arm Assembly Process: 3D Printed Arm with Advanced Actuators and Competitive Industrial Robot Price”