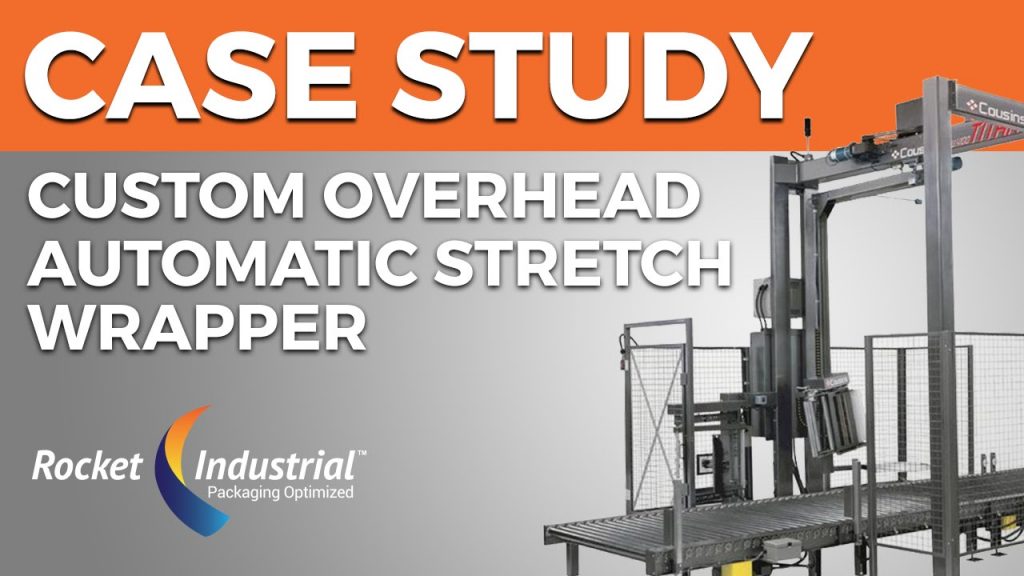

Title: Industrial Orbital Stretch Wrapper: Customized Solution for Beverage Distribution | Case Study Video

Description:

Introduction:

Welcome to our case study video featuring the Industrial Orbital Stretch Wrapper, a highly customized and efficient solution designed specifically for a beverage distributor. In this video, we showcase the key features, operational steps, and the benefits of this custom overhead stretch wrapper. Join us to explore how this innovative wrapping solution optimizes the packaging process and enhances productivity for beverage distributors.

Video Content:

Our Industrial Orbital Stretch Wrapper is a state-of-the-art automated machine that revolutionizes the packaging process for beverage distributors. This case study video provides a comprehensive overview of its unique features, including its customizability, efficiency, and reliability.

Key Highlights:

1. Customization: We delve into the custom design of the Industrial Orbital Stretch Wrapper, tailored specifically to meet the unique needs of beverage distributors. This includes considerations such as packaging size, material, and efficiency requirements.

2. Enhanced Efficiency: Discover how this orbital stretch wrapper improves the productivity of beverage distributors by automating the wrapping process. By reducing manual labor and streamlining operations, it significantly increases output and reduces costs.

3. Advanced Technology: Gain insights into the cutting-edge technology employed in our Industrial Orbital Stretch Wrapper, ensuring precise and consistent wrapping results. The machine’s intuitive controls and user-friendly interface contribute to seamless operation.

4. Optimal Protection: Learn about the superior protection provided by this stretch wrapper, safeguarding beverage products during transit and storage. The orbital wrapping process ensures secure and tight packaging, minimizing the risk of damage or spoilage.

Operational Steps:

We walk you through the step-by-step operation of the Industrial Orbital Stretch Wrapper, highlighting its user-friendly interface and intuitive controls. From initial setup and customization to the wrapping process itself, we showcase how easily this machine can be integrated into your beverage distribution operations.

Call to Action:

If you found this video insightful and informative, please consider liking, subscribing, and sharing it with others who may benefit from this innovative solution. Don’t forget to hit the notification bell to stay updated with our latest videos.

Additional Tags and Keywords: Industrial Orbital Stretch Wrapper, Custom Overhead Stretch Wrapper, beverage distributor, packaging solution, wrapping machine, automated packaging, efficiency improvement, protective packaging.

Hashtags:

#IndustrialOrbitalStretchWrapper #CustomStretchWrapper #BeverageDistribution #PackagingSolution #EfficiencyImprovement #ProtectivePackaging

Title: Optimizing Efficiency and Productivity with a Custom Overhead Stretch Wrapper

Introduction:

The following case study examines the implementation of a custom overhead stretch wrapper solution for a manufacturing company. This tilter aims to enhance efficiency and productivity in the packaging process, leading to cost savings and improved customer satisfaction.

Objective:

The primary objective of this case study is to analyze the impact of implementing a custom overhead stretch wrapper on a company’s packaging process. The tilter aims to optimize efficiency by streamlining operations, reducing labor costs, and minimizing material waste.

Methodology:

1. Assessing the packaging process: The study will begin by evaluating the existing packaging process, identifying pain points, and analyzing potential areas for improvement.

2. Design and customization: A custom overhead stretch wrapper will be designed, taking into consideration the specific requirements and constraints of the manufacturing company.

3. Implementation and testing: The custom tilter will be installed and thoroughly tested in the manufacturing facility to evaluate its performance, reliability, and impact on efficiency.

4. Data collection and analysis: Data on labor costs, production throughput, material waste, and customer satisfaction will be collected and analyzed to assess the overall effectiveness of the custom overhead stretch wrapper.

5. Comparison with previous process: A comparative analysis will be conducted to determine the improvements achieved with the custom tilter compared to the previous packaging process.

Results:

1. Increased efficiency: The implementation of the custom overhead stretch wrapper will reduce the time required for packaging, leading to increased productivity and throughput.

2. Labor cost reduction: By automating the packaging process, the tilter will significantly reduce the need for manual labor, resulting in cost savings for the company.

3. Minimized material waste: The custom tilter will optimize the use of packaging materials, reducing waste and enhancing sustainability.

4. Enhanced customer satisfaction: The consistent and professional packaging provided by the custom tilter will improve the quality of products received by customers, contributing to higher satisfaction levels.

Conclusion:

This case study demonstrates the positive impact of implementing a custom overhead stretch wrapper on a manufacturing company’s packaging process. The tilter enhances efficiency, reduces labor costs, minimizes material waste, and improves customer satisfaction. The findings of this study can serve as a valuable reference for other companies seeking to optimize their packaging operations.Orbital Stretch Wrapper

#Case #Study #Custom #Overhead #Stretch #Wrapper