Title: High-Speed Automatic Packing Line | Fully Automatic Silicone Cartridges Packaging | Nannini Renato Machinery

Description:

Introduction:

Welcome to our high-speed automatic packing line video, showcasing the innovative technology behind fully automatic silicone cartridges packaging. In collaboration with Nannini Renato Machinery, this packaging line incorporates the advanced C80E automatic cartridges filling machine and GRI system, ensuring efficient and precise operations. Join us as we explore the features and benefits of this high-speed packaging line.

Video Content:

1. Overview of the High-Speed Automatic Packing Line:

– Discover the cutting-edge technology employed in our high-speed automatic packing line.

– Experience the seamless integration of the C80E automatic cartridges filling machine.

– Learn how Nannini Renato Machinery enhances the packaging process for silicone cartridges.

2. Key Features of the Fully Automatic Silicone Cartridges Packaging:

– Witness the incredible speed and accuracy of the packaging line.

– Explore the versatility of the system, accommodating various cartridge sizes and materials.

– Understand the importance of automated filling and packaging for increased productivity.

3. Operation Steps:

– Step 1: Loading cartridges onto the conveyor belt.

– Step 2: The C80E automatic cartridges filling machine accurately fills the cartridges.

– Step 3: The GRI system ensures proper sealing and labeling of the cartridges.

– Step 4: Packed cartridges are securely discharged from the line.

4. Benefits and Advantages:

– Experience the significant time savings and increased production efficiency.

– Eliminate human error with the precise automated filling and packaging process.

– Enhance product quality and consistency with the high-speed packaging line.

Call to Action:

If you found this video informative and intriguing, we encourage you to like, subscribe, and share it with others who may benefit from this advanced packaging technology. Stay updated with our latest videos for more industry insights and innovative solutions.

Additional Tags and Keywords: high-speed packing line, automatic silicone cartridges packaging, Nannini Renato Machinery, C80E automatic cartridges filling machine, GRI system, automated packaging, efficient packaging line, increased productivity, precision packaging.

Hashtags: #HighSpeedPackingLine #AutomaticPackaging #SiliconeCartridgesPackaging #NanniniRenatoMachinery #C80E #GRI #AutomatedFilling #EfficientPackaging

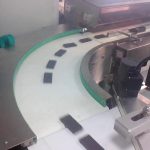

Here’s an example of a tilter for a fully automatic silicone cartridge high-speed packaging line:

1. Objective:

To design and develop a tilter for a fully automatic silicone cartridge high-speed packaging line that efficiently rotates the cartridges to their desired orientation before further processing.

2. Requirements:

– The tilter should be able to handle a high-speed production line, accommodating the required number of cartridges per minute.

– It should be capable of rotating the cartridges to a specific angle or orientation as per the packaging requirements.

– The tilter should be user-friendly, easy to operate, and require minimal maintenance.

– It should have safety features to prevent accidents or damage to the cartridges or the production line.

3. Design and Implementation:

– The tilter will consist of a conveyor belt system that transports the silicone cartridges to the tilting mechanism.

– The tilting mechanism will be designed to rotate the cartridges to the desired angle or orientation before being released back onto the conveyor belt.

– The tilting mechanism can be equipped with a motor and gears to provide the necessary rotating force.

– Sensors will be incorporated to detect the position and orientation of the cartridges as they approach the tilter.

– A programmable logic controller (PLC) will be used to control the tilter’s operation, including speed, angle, and timing.

– Safety features such as emergency stop buttons, safety barriers, and interlocks will be included to ensure operator safety and prevent damage to the cartridges or the production line.

– The tilter will be designed using durable materials to withstand continuous operation and minimize maintenance requirements.

4. Testing and Validation:

– The tilter will undergo rigorous testing to ensure its performance and reliability.

– The testing will include running the tilter at the maximum specified production speed to verify its capability to handle high-speed operations.

– The accuracy and consistency of the tilting mechanism will be tested by measuring the resulting angle or orientation of the cartridges.

– The tilter will also be tested for safety features, ensuring proper functioning of emergency stop buttons, safety barriers, and interlocks.

5. Installation and Maintenance:

– The tilter will be installed in the silicone cartridge high-speed packaging line, integrated with the existing conveyor system.

– Proper training will be provided to the operators regarding the tilter’s operation, safety procedures, and maintenance requirements.

– Regular maintenance and inspection will be conducted to ensure the tilter’s optimal performance and longevity.

By implementing this tilter design, the fully automatic silicone cartridge high-speed packaging line will be able to efficiently handle the rotation of cartridges, ensuring they are correctly oriented for further processing and packaging operations. coil packing line

#Fully #Automatic #silicone #cartridges #high #speed #packaging #line