Plastic Injection Machine Price: A Comprehensive Guide

Introduction

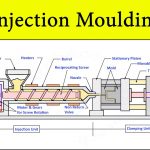

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold to create various plastic products. This process is efficient, cost-effective, and offers high precision and repeatability. However, before investing in a plastic injection machine, it is crucial to understand the factors that affect its price. In this article, we will explore the various aspects of plastic injection machine pricing, including the 100 gms plastic injection molding machine offered by Vishwakarma plastic machinery.

Understanding Plastic Injection Machine Pricing Factors

1. Machine Type and Size

The type and size of the plastic injection machine play a significant role in determining its price. Different machines cater to different production needs. Smaller machines are suitable for low-volume production, while larger machines are ideal for high-volume production. The complexity of the machine’s design and its capabilities also impact the price.

2. Machine Features and Technology

Plastic injection machines come with a range of features and technologies that enhance their performance and efficiency. Advanced features like automated controls, multi-cavity molds, and robotic systems can increase the machine’s price. These features not only improve productivity but also ensure consistent product quality.

3. Brand Reputation and Quality

The reputation and quality of the manufacturer also influence the price of a plastic injection machine. Established brands with a history of producing reliable and durable machines often come at a premium price. However, investing in a reputable brand ensures a higher level of customer support, spare parts availability, and overall machine reliability.

4. Machine Capacity and Output

The production capacity and output of a plastic injection machine are crucial factors in determining its price. Machines with higher tonnage and faster cycle times tend to be more expensive. It is essential to assess your production requirements accurately to choose a machine that meets your specific needs without overspending.

Vishwakarma Plastic Machinery’s 100 gms Plastic Injection Molding Machine

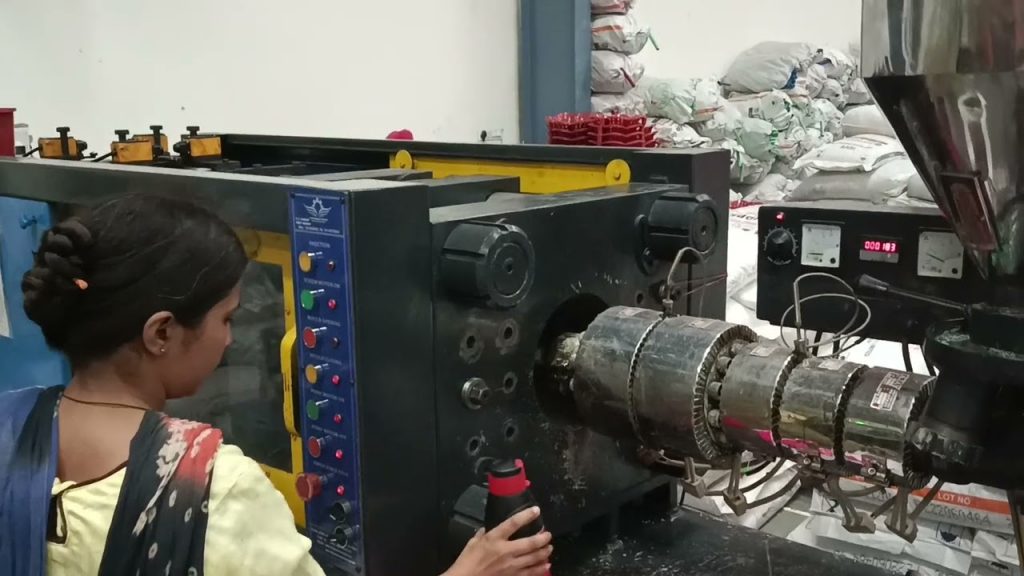

Vishwakarma Plastic Machinery is an ISO 9001:2015 certified company known for its high-quality plastic injection machines. Their 100 gms plastic injection molding machine is a versatile and efficient solution for small to medium-sized production runs. This machine offers precise control over the injection process, ensuring consistent part quality.

With its robust construction and advanced features, Vishwakarma’s 100 gms plastic injection molding machine delivers excellent performance and reliability. The machine is designed for easy operation and maintenance, minimizing downtime and maximizing productivity. Vishwakarma’s commitment to quality and customer satisfaction makes them a trusted choice in the market.

Conclusion

Investing in a plastic injection machine requires careful consideration of various factors, including machine type and size, features and technology, brand reputation, and production capacity. By understanding these factors and evaluating your specific requirements, you can make an informed decision and find a machine that offers the best value for your investment.

Check the plastic injection machine price at Vishwakarma Plastic Machinery and explore their range of high-quality machines. With their expertise and commitment to excellence, they can provide you with a professional solution for all your plastic injection molding needs.

Note: This article is for informational purposes only. Prices and specifications may vary. Plastic Injection Machine

“Efficient and Reliable Plastic Injection Moulding Machine: ISO 9001:2015 Certified – Affordable Price!”