Check out the leading manufacturer for the best coil packing solution here:

Plastic Injection Machine Reviews: A Comprehensive Guide to Finding the Perfect Machine for Your Needs

In the world of manufacturing, plastic injection machines play a crucial role in the production of various plastic products. Whether you are a small cavities plastic part mould maker or a factory owner looking to invest in a new injection molding machine, finding the right equipment can be a daunting task. With so many options available in the market, it’s essential to understand the different aspects of these machines and make an informed decision. In this article, we will provide a comprehensive review of plastic injection machines, covering their features, benefits, and considerations, to help you find the perfect machine for your needs.

Introduction: The Importance of Plastic Injection Machines

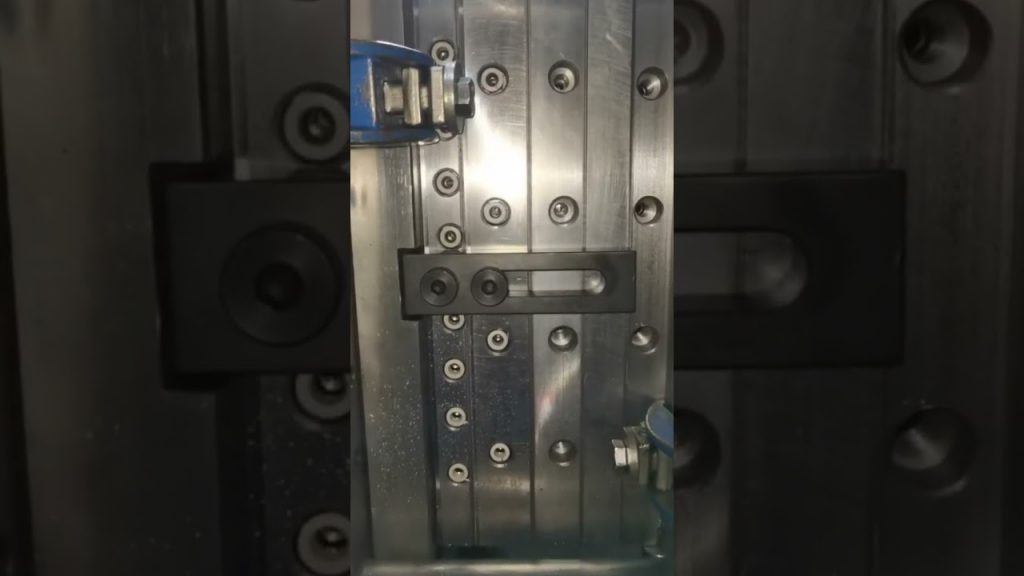

Plastic injection machines are used to create plastic products by injecting molten plastic into a mold. This process is known as injection molding and is widely used across industries such as automotive, medical, packaging, and consumer goods. Whether it’s producing intricate components or simple household items, injection molding offers high precision and efficiency, making it the preferred choice for many manufacturers.

Plastic Injection Machine Reviews: Finding the Right Machine for Your Needs

When it comes to choosing a plastic injection machine, there are several factors to consider. To make the process easier for you, we have gathered reviews of some of the top machines available in the market, highlighting their key features and benefits.

1. Machine A: The Perfect Combination of Performance and Precision

Machine A is a highly reliable and versatile plastic injection machine, suitable for both small cavities plastic part mould makers and large-scale factories. With its advanced control system and high-speed injection capabilities, Machine A ensures precise and consistent results, even for complex molds. Additionally, its user-friendly interface and intuitive controls make it easy to operate, reducing downtime and increasing productivity.

2. Machine B: The Cost-Effective Solution for Small-Scale Production

If you are a small cavities plastic part mould maker or a startup with limited production requirements, Machine B offers a cost-effective solution without compromising on quality. This machine is compact, energy-efficient, and provides excellent repeatability, making it ideal for low-volume production. Its modular design allows for easy customization and future scalability, ensuring that your investment remains relevant as your business grows.

3. Machine C: High-Speed Performance for Large-Scale Production

For factories with high-volume production needs, Machine C offers exceptional speed and efficiency. Its advanced servo motor technology enables precise control of injection speed and pressure, resulting in consistent and high-quality output. With a large mold carrying capacity and a robust clamping system, Machine C can handle even the most demanding production requirements with ease.

Considerations When Choosing a Plastic Injection Machine

While the reviews above provide insights into specific machines, it’s essential to consider the following factors when selecting a plastic injection machine:

1. Production Volume: Determine your production volume requirements to choose a machine that can meet your production targets efficiently.

2. Mold Size and Complexity: Consider the size and complexity of the molds you will be using to ensure compatibility with the machine’s specifications.

3. Precision and Consistency: Look for machines that offer precise control over injection speed, pressure, and temperature to achieve consistent results.

4. Energy Efficiency: Opt for machines that are energy-efficient to minimize operational costs and reduce environmental impact.

Conclusion: Finding the Perfect Plastic Injection Machine for Your Needs

Investing in the right plastic injection machine is crucial for the success of your manufacturing operations. By understanding the features, benefits, and considerations outlined in this article, you can make an informed decision that aligns with your specific needs and requirements. Whether you are a small cavities plastic part mould maker or a factory owner, there is a perfect machine out there waiting to elevate your production capabilities.

So why wait? Explore the wide range of plastic injection machines available in the market and find the one that suits your needs perfectly. Remember, the right machine can make all the difference in achieving optimal results and staying ahead in the competitive manufacturing industry.

Check out the leading manufacturer for the best coil packing solution here: [Insert manufacturer’s website/link] Plastic Injection Machine

“Optimizing Injection Molding for Small Cavities: Insights from a Plastic Part Mould Maker Factory”