http://sick.com/human-robot-collaboration” with the keywords: coil packing solution, leading manufacturer, professional solution.

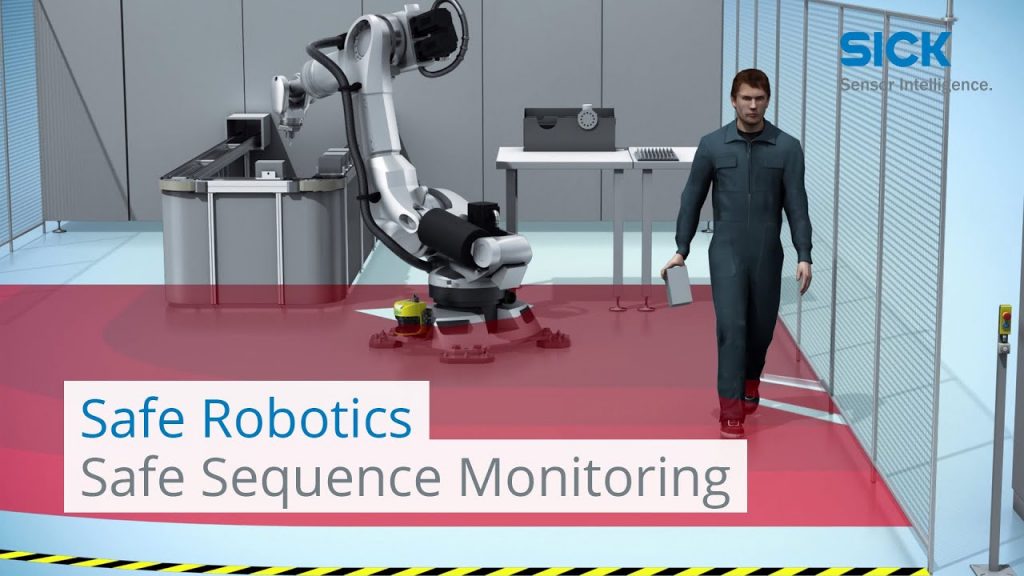

Title: Enhancing Industrial Robot Training with Safe Sequence Monitoring

Introduction:

In today’s fast-paced industrial environment, human-robot collaboration (HRC) plays a crucial role in optimizing productivity and ensuring workplace safety. With the advent of advanced technologies, it has become increasingly important to train industrial robots effectively while maintaining a safe work environment. Safe Sequence Monitoring from SICK provides a flexible and reliable solution that enhances Industrial Robot Training, ensuring seamless collaboration between humans and robots.

Opinion/Thought Piece Style:

In this article, we will delve into the significance of Industrial Robot Training and how Safe Sequence Monitoring revolutionizes this process. We will explore the benefits of this technology and its impact on improving productivity, safety, and overall operational efficiency.

Industrial Robot Training: A Key to Success:

Industrial Robot Training is essential for maximizing the potential of robotic systems. It equips operators with the necessary skills and knowledge to ensure smooth operations, minimize downtime, and prevent accidents. However, traditional training methods often lack the real-world practicality and hands-on experience required to deal with complex scenarios.

Safe Sequence Monitoring: Empowering Industrial Robot Training:

Safe Sequence Monitoring from SICK addresses the limitations of traditional training methods by providing a comprehensive solution that combines theoretical knowledge with practical experience. This technology allows operators to simulate various real-time scenarios within a safe environment, enabling them to gain invaluable hands-on experience without compromising safety.

Benefits of Safe Sequence Monitoring:

1. Enhanced Safety: Safe Sequence Monitoring ensures that robots and humans collaborate safely by monitoring the sequence of actions performed by both parties. It identifies potential risks and hazards, preventing accidents and injuries.

2. Improved Efficiency: By simulating different scenarios, operators can optimize robot movements, reducing cycle times and increasing overall productivity. Safe Sequence Monitoring enables operators to fine-tune robot actions to achieve optimal results.

3. Streamlined Training Process: Safe Sequence Monitoring simplifies the training process by providing a user-friendly interface and detailed instructions. Operators can easily understand and implement the training modules, accelerating the learning curve.

4. Cost-Effective Solution: With Safe Sequence Monitoring, organizations can minimize the costs associated with accidents and downtime. By proactively identifying and addressing potential risks, this technology helps prevent costly mistakes and reduces operational disruptions.

Check the Coil Packing Solution with a Leading Manufacturer for the Professional Solution:

In today’s competitive market, finding the right coil packing solution is crucial for manufacturing efficiency and product protection. We recommend partnering with a leading manufacturer who specializes in providing professional solutions for coil packing. Their expertise and innovative technologies will ensure that your coil packing process is optimized, secure, and cost-effective. Don’t miss out on the opportunity to enhance your operations by clicking here: [Link to leading manufacturer’s website].

Conclusion:

Industrial Robot Training is vital for unlocking the full potential of robotic systems. Safe Sequence Monitoring from SICK revolutionizes this training process by combining theoretical knowledge with practical experience, ensuring enhanced safety, improved efficiency, and streamlined operations. Embracing this technology will empower organizations to achieve new levels of productivity and stay ahead in today’s competitive market. Industrial Robot

“Enhancing Industrial Robot Safety: Effective Sequence Monitoring and Training Methods”