Are you looking for a cutting-edge solution to improve the efficiency and flexibility of your industrial operations? Look no further than MIRAI, a revolutionary technology that enables industrial and collaborative robots to handle variances in position, shape, and movement within the workspace. In this YouTube video article, we will explore the wide range of applications for industrial robots and how MIRAI has transformed the way we approach automation.

Industrial Robot Applications: Revolutionizing Automation

Industrial robots have been a game-changer in various industries, streamlining processes and increasing productivity. With their ability to perform repetitive tasks with precision and speed, they have become an indispensable tool for manufacturers worldwide. However, traditional industrial robots have limitations when it comes to handling variances in the workspace. This is where MIRAI comes into play.

Micropsi Industries, a leading innovator in robotic automation, has introduced MIRAI, a groundbreaking technology that empowers industrial robots to adapt to changes in position, shape, or movement within the workspace. This opens up a whole new realm of possibilities for automation, allowing businesses to overcome the challenges posed by unpredictable factors in their operations.

MIRAI: Enabling Robot Applications with Workspace Variances

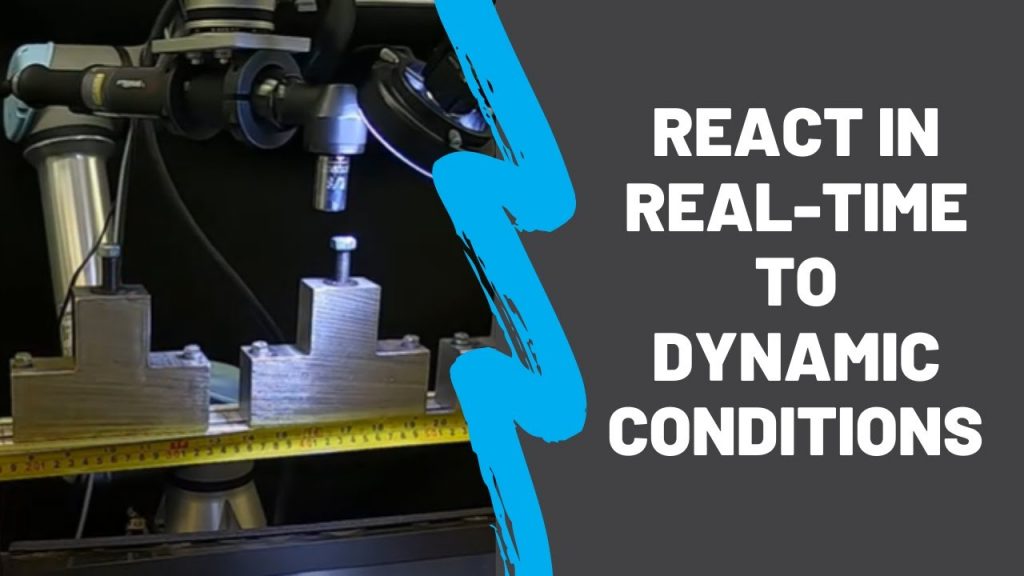

MIRAI leverages advanced algorithms and machine learning to enable industrial robots to dynamically adjust their movements and actions based on real-time feedback. This means that robots equipped with MIRAI can handle variations in the position of objects, adapt to changes in shape, and respond to unexpected movements within the workspace. This level of adaptability and flexibility is unprecedented in the world of automation.

The applications for industrial robots with MIRAI are virtually limitless. From manufacturing processes that involve assembling components with slight variations in position to logistics operations that require robots to adapt to irregularly shaped packages, MIRAI empowers robots to handle these challenges seamlessly. This not only improves operational efficiency but also reduces the need for human intervention, ultimately saving time and resources.

Case Study: The Power of MIRAI in Action

To illustrate the capabilities of MIRAI, let’s dive into a real-world case study. Imagine a factory that produces electronic components. Traditionally, assembling these components would require precise positioning, which would be challenging for a conventional industrial robot. However, with MIRAI, the robot can adapt its movements based on the exact position of each component, eliminating the need for manual adjustments or repositioning. This significantly speeds up the assembly process, leading to higher productivity and reduced costs.

The Future of Industrial Automation

As technology continues to evolve, the future of industrial automation looks promising. With MIRAI leading the way, we can expect to see even more advancements in the field of robotics. The ability to handle variances in the workspace opens up endless possibilities for automation, making processes more efficient, cost-effective, and flexible.

In conclusion, the integration of MIRAI into industrial robots has revolutionized the way we approach automation. The ability to handle variances in position, shape, or movement within the workspace has opened up a world of possibilities for businesses across various industries. With MIRAI, industrial robots are now capable of adapting to changes in real-time, improving operational efficiency, and reducing the need for human intervention.

Check the coil packing solution with a leading manufacturer for a professional solution just here. Industrial Robot

“Revolutionizing Robot Applications: Adapting to Varied Workspaces and Industrial Environments”