Title: Industrial Automatic Packing Line – Streamlining the Packaging Process for Industrial Polyester Yarn

Description:

Introduction:

Welcome to our comprehensive video on the Industrial Automatic Packing Line, specifically designed to optimize the packaging process for industrial polyester yarn. In this video, we will delve into the key features, benefits, and operation steps of this advanced packaging solution. Stay tuned to discover how this automated system can revolutionize your packaging efficiency and productivity.

Video Content:

1. Key Features:

Explore the cutting-edge features of our Industrial Automatic Packing Line. This state-of-the-art system incorporates advanced technology and innovative design elements to ensure seamless and efficient packaging of industrial polyester yarn. From precise measurements to automated sealing, this packing line offers a range of features to enhance your packaging process.

2. Benefits:

Discover the manifold benefits of implementing an Industrial Automatic Packing Line for industrial polyester yarn. By utilizing this automated system, you can significantly reduce manual labor, eliminate errors, and enhance overall productivity. Additionally, the system ensures consistent packaging quality, minimizing material wastage and reducing costs.

3. Operation Steps:

Learn about the step-by-step process involved in operating the Industrial Automatic Packing Line. We will guide you through the setup, configuration, and calibration of the system. From loading the yarn onto the conveyor to selecting the appropriate packaging parameters, each operation step will be thoroughly explained, ensuring a seamless integration of this packing line into your production process.

Call to Action:

If you found this video insightful and informative, we encourage you to like, subscribe, and share it with your colleagues and industry peers. By staying connected with our channel, you will gain access to more valuable content related to industrial packaging solutions and automation.

Additional Tags and Keywords:

Industrial Automatic Packing Line, automated packaging solutions, industrial polyester yarn, packaging efficiency, packaging process optimization, advanced technology, innovative design, precise measurements, automated sealing, manual labor reduction, consistent packaging quality, material wastage reduction, productivity enhancement, step-by-step operation, setup, configuration, calibration.

Hashtags:

#IndustrialAutomaticPackingLine #PackagingEfficiency #PolyesterYarn #Automation #ProductivityEnhancement

Title: Automated Tilter for Industrial Polyester Yarn Packing Line

Introduction:

The following document presents a detailed tilter design for an automatic packing line of industrial polyester yarn. The tilter aims to streamline the packaging process, enhance efficiency, and ensure the safe handling of polyester yarn during transportation and storage. The proposed design incorporates advanced technology and innovative features to automate the tilting process, minimizing human intervention and maximizing productivity.

1. Objective:

The primary objective of the automated tilter is to facilitate the seamless and efficient packaging of industrial polyester yarn on the packing line. The tilter will ensure the precise alignment and orientation of yarn spools, reducing the risk of damage, tangling, or entanglement during transportation and storage.

2. Design Specifications:

– Compatibility: The tilter should be compatible with different sizes and weights of polyester yarn spools commonly used in the industry.

– Automation: The tilter should have a fully automated operation with minimal human intervention required.

– Stability: The tilter should maintain stability while tilting the spools to prevent any imbalance or accidents.

– Safety: The tilter should incorporate safety features, such as emergency stop buttons, protective enclosures, and sensors to detect any abnormal conditions or obstructions during operation.

– Speed and Efficiency: The tilter should be capable of handling a high volume of spools with quick and precise tilting actions.

– Customizability: The tilter should be adjustable to accommodate different packaging requirements and spool sizes.

3. Key Components and Mechanism:

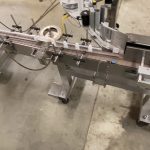

– Conveyor Belt: A conveyor belt system will transport the polyester yarn spools to the tilter.

– Tilting Platform: A robust tilting platform equipped with motorized rollers will receive the spools from the conveyor belt and tilt them to the desired angle. The platform will have adjustable settings to cater to different packaging needs.

– Control Panel: A user-friendly control panel will enable operators to input specific tilting angles, adjust settings, and monitor the overall operation of the tilter.

– Sensors: Proximity sensors will detect the presence of spools on the conveyor belt, ensuring smooth and accurate tilting operations.

– Safety Features: Emergency stop buttons, protective enclosures, and safety sensors will be integrated to ensure the safety of operators and prevent accidents.

– Connectivity: The tilter will be compatible with the existing packing line infrastructure, allowing for seamless integration and data exchange.

4. Benefits:

– Improved Efficiency: The automated tilter will significantly reduce manual labor, increasing productivity and throughput on the packing line.

– Enhanced Product Quality: By ensuring proper alignment and orientation, the tilter will minimize the risk of damage or tangling, resulting in superior product quality.

– Cost Savings: The reduction in manual labor and improved product quality will lead to cost savings through increased efficiency and customer satisfaction.

– Flexibility: The tilter’s adjustable settings will enable the packing line to adapt to various packaging requirements, reducing the need for additional equipment.

Conclusion:

The proposed automated tilter for the industrial polyester yarn packing line offers a comprehensive solution to enhance efficiency and streamline the packaging process. By automating the tilting operation, the tilter ensures the safe handling of polyester yarn and maximizes productivity. The incorporation of advanced technology and safety features guarantees a reliable and efficient solution for the packaging industry. coil packing line

#Automatic #packing #line #industrial #polyester #yarn