Check out our website for more information on our top-of-the-line coil packing solutions.”

Title: Revolutionizing Injection Molding with Industrial Plastic Injection Machines

Introduction:

In today’s fast-paced manufacturing industry, efficiency and accuracy are paramount. One technology that has revolutionized the production process is the industrial plastic injection machine. With its precise and rapid molding capabilities, this machine has become an indispensable tool for manufacturers worldwide. In this article, we will delve into the world of injection molding robots and explore the benefits they bring to the table.

Section 1: The Power of Industrial Plastic Injection Machines

Industrial plastic injection machines have transformed the manufacturing landscape by streamlining the process of creating plastic parts. These machines utilize high-pressure injection of molten plastic into specially designed molds, resulting in the production of a wide range of products, from small components to large-scale items. The use of such machines has significantly reduced production time and costs, making it a preferred choice for manufacturers across various industries.

Section 2: ABS Plastic Injection Molding and its Applications

One of the most commonly used materials in injection molding is ABS plastic. Acrylonitrile Butadiene Styrene (ABS) is a versatile thermoplastic renowned for its strength, durability, and impact resistance. It is widely used in the automotive, electronics, and consumer goods industries for manufacturing components such as casings, panels, and enclosures. ABS plastic injection molding offers superior dimensional stability, excellent surface finish, and the ability to produce intricate designs with ease.

Section 3: The Role of Injection Molding Robots

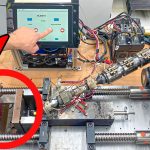

Injection molding robots play a crucial role in enhancing the efficiency and accuracy of the injection molding process. These robots are equipped with advanced features such as precision control, rapid movement, and intelligent programming, allowing them to perform complex tasks with utmost precision. They can handle various operations, including mold changing, part removal, quality inspection, and packaging, eliminating the need for manual labor and reducing the risk of errors.

Section 4: Advantages of Industrial Plastic Injection Machines

4.1 Increased Productivity: Industrial plastic injection machines can operate continuously, resulting in higher production rates and reduced downtime. They can produce a large number of parts in a short span of time, meeting the demands of high-volume manufacturing.

4.2 Cost Efficiency: By automating the injection molding process, manufacturers can save on labor costs and minimize waste. Additionally, the precise control offered by these machines ensures minimal material wastage, further contributing to cost savings.

4.3 Consistent Quality: Injection molding robots ensure consistent quality by maintaining precise temperature and pressure control throughout the molding process. This results in products with uniform dimensions and superior surface finish.

4.4 Flexibility: Industrial plastic injection machines are versatile and can adapt to different mold designs and product requirements. This flexibility allows manufacturers to cater to a wide range of customer needs and explore new markets.

Section 5: The Future of Injection Molding

As technology continues to advance, the future of injection molding looks promising. Innovations such as 3D printing and smart robotics are set to revolutionize the industry further. With the integration of artificial intelligence and machine learning, injection molding robots will become even more efficient and autonomous, enabling manufacturers to achieve higher levels of productivity and precision.

Conclusion:

Industrial plastic injection machines have transformed the manufacturing industry by providing efficient, accurate, and cost-effective solutions for producing plastic parts. The use of ABS plastic in injection molding further enhances the versatility and durability of the end products. With the continuous advancements in technology, the future of injection molding looks bright, promising even greater efficiency and productivity. So, if you are in the manufacturing industry, it’s time to embrace the power of industrial plastic injection machines and witness the transformation in your production process.

Check out our website for more information on our top-of-the-line coil packing solutions. Plastic Injection Machine

“Mastering ABS Plastic Injection Molding: Unveiling the Secrets of Industrial Plastic Injection Machines”