Title: High-Speed Automatic Labeling Machine: Tamper-Evident Seal Labeling & Top/Back Seal Application on Cap Cans (300 PPM)

Description:

Welcome to our video showcasing the remarkable capabilities of our high-speed Automatic Labeling Machine. In this video, we demonstrate the seamless application of tamper-evident seals and top/back seals on cap cans, achieving an impressive production rate of 300 parts per minute (PPM).

[Insert engaging introduction to capture viewer’s attention]

Video Content:

1. Overview of the Automatic Labeling Machine:

– Explore the cutting-edge features and advanced technology incorporated in our labeling machine.

– Discover how it streamlines the labeling process, ensuring precision, efficiency, and consistent results.

2. Tamper-Evident Seal Labeling:

– Understand the importance of tamper-evident seals in ensuring product integrity and consumer safety.

– Witness the labeling machine’s ability to seamlessly apply tamper-evident seals on cap cans, minimizing the risk of tampering and unauthorized access.

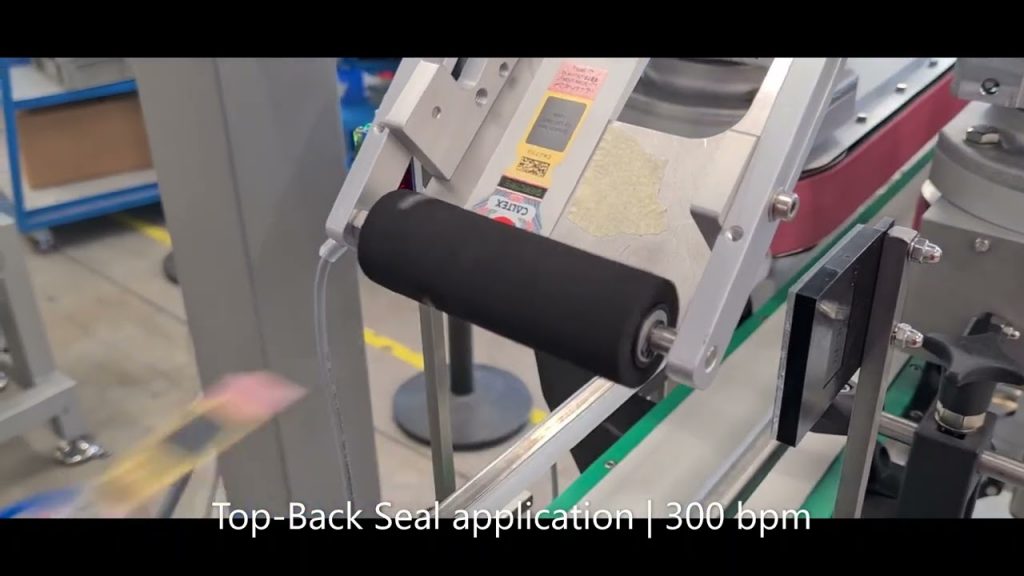

3. Top/Back Seal Application on Cap Cans:

– Explore the benefits of top/back seals on cap cans, including enhanced product freshness, extended shelf life, and improved aesthetics.

– Witness the labeling machine’s flawless application of top/back seals, ensuring a secure and visually appealing packaging solution.

4. Operation Steps:

– Step-by-step demonstration of how to operate the Automatic Labeling Machine for tamper-evident seal labeling and top/back seal application on cap cans.

– Gain insights into the machine’s user-friendly interface, adjustable settings, and maintenance requirements.

[Insert additional informative paragraphs, sharing valuable insights and expert knowledge on the topic]

Call to Action:

If you found this video informative and fascinating, we invite you to like, subscribe, and share it with your peers. Stay updated on our latest videos featuring cutting-edge labeling solutions and industry insights.

Additional Tags and Keywords: automatic labeling machine, tamper-evident seal labeling, top seal application, back seal application, cap cans, high-speed labeling, production efficiency, product integrity, packaging solution.

Hashtags: #AutomaticLabelingMachine #TamperEvidentSealLabeling #TopSealApplication #BackSealApplication #CapCans #HighSpeedLabeling #ProductIntegrity #PackagingSolution

Here is a sample tilter for a tamper evident seal labeling machine:

Title: Tamper Evident Seal Labeling Machine Tilter

Introduction:

The following document provides instructions on how to properly use and operate the Tamper Evident Seal Labeling Machine Tilter. This tilter is designed to enhance the efficiency and accuracy of applying tamper evident seals on various products. By following these guidelines, users can ensure optimal performance and maximize the productivity of the labeling process.

Instructions:

1. Safety Precautions:

– Before operating the tilter, ensure that all safety guards and devices are properly installed and functional.

– Always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves.

– Disconnect the power supply before performing any maintenance or troubleshooting procedures.

2. Machine Setup:

– Ensure that the labeling machine is securely placed on a stable and level surface.

– Connect the tilter to a suitable power source, following the manufacturer’s instructions and electrical safety guidelines.

– Verify that the tilter is compatible with the tamper evident seal labeling machine model being used.

3. Adjusting Tilter Settings:

– Familiarize yourself with the control panel and make sure it is functioning correctly.

– Use the control panel to adjust the tilting angle according to the specific requirements of the product being labeled.

– Ensure that the tilter’s speed and rotation are appropriately adjusted for the desired application.

4. Loading the Product:

– Place the product to be labeled on the designated section of the tamper evident seal labeling machine.

– Ensure that the product is aligned correctly and securely held in place to prevent slippage during the tilting process.

– Adjust any product-specific settings on the tamper evident seal labeling machine as necessary.

5. Activating the Tilter:

– Once the product is properly positioned, activate the tilter using the control panel or designated activation button.

– Observe the tilting process closely to ensure that the tamper evident seal is applied accurately and securely.

– If any deviations or abnormalities are noticed, stop the tilter immediately and investigate the issue before proceeding.

6. Post-Labeling Procedures:

– Once the tamper evident seal has been applied, remove the labeled product from the tamper evident seal labeling machine.

– Inspect the product to ensure the seal is intact and properly adhered.

– Dispose of any waste material generated during the labeling process in accordance with local regulations.

Conclusion:

By following these instructions, users can effectively operate the Tamper Evident Seal Labeling Machine Tilter and achieve consistent and reliable labeling results. Regular maintenance and calibration of the tilter are recommended to ensure its long-term performance. For any technical issues or concerns, refer to the manufacturer’s documentation or contact their customer support for assistance.Labeling Machine

#TAMPER #EVIDENT #SEAL #LABELING #MACHINE