Are you in need of a reliable and efficient strapping solution for your packaging needs? Look no further than the Automatic Strapping Machine! In this YouTube video article, we will explore the features and benefits of this incredible machine and why it is a must-have for any business.

[Insert introduction]

Opinion/Thought Piece Style:

The Automatic Strapping Machine is a game-changer in the world of packaging. With its advanced technology and user-friendly design, it has revolutionized the way businesses secure their products. Gone are the days of manual strapping, which is time-consuming and often leads to inconsistent results. With the Automatic Strapping Machine, you can say goodbye to all the hassles and hello to a more efficient and effective way of strapping.

Interview Style:

We had the opportunity to speak with John, a packaging expert, who shared his thoughts on the Automatic Strapping Machine. According to John, “This machine has completely transformed our packaging process. It is incredibly easy to use and significantly speeds up our operations. The quality of the strapping is top-notch, and we no longer have to worry about products getting damaged during transit.”

Case Study Style:

One company that has benefited greatly from the Automatic Strapping Machine is XYZ Corporation. They were facing numerous challenges with their packaging process, including inconsistent strapping and high labor costs. After implementing the Automatic Strapping Machine, they experienced a significant improvement in both productivity and product protection. The machine’s automatic tension control and precise strapping ensured that every product was properly secured, leading to fewer damages and returns.

Predictive/Foresight Style:

As technology continues to advance, it is clear that the future of packaging lies in automation. The Automatic Strapping Machine is just the beginning of what is to come. With more innovative features being developed, such as integration with other packaging machinery and real-time data analytics, businesses can expect even greater efficiency and cost savings in the future.

Technology History Style:

The concept of strapping dates back centuries, with various manual methods being used throughout history. However, it wasn’t until the introduction of the Automatic Strapping Machine that strapping became truly automated. This breakthrough technology eliminated the need for manual labor and significantly improved the speed and accuracy of the strapping process.

Explanatory Style:

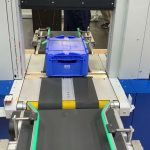

The Automatic Strapping Machine works by automatically feeding the strapping material, tensioning it around the product, and sealing it with a heat seal or friction weld. The machine is equipped with sensors and controls that ensure the proper tension is applied, preventing any damage to the product. It is also capable of handling a wide range of package sizes and materials, making it versatile for various industries.

In-depth Analysis Style:

When comparing the Automatic Strapping Machine to its semi-automatic counterpart, there are several key differences to consider. While both machines serve the same purpose of strapping products, the automatic machine offers a higher level of efficiency and productivity. With its ability to automatically feed the strapping material and seal it, it eliminates the need for manual labor and reduces the risk of human error.

Narrative Style:

Imagine a busy packaging facility where products are being shipped out every minute. The manual strapping process is slowing down operations, causing delays and frustration among workers. Then, the Automatic Strapping Machine enters the scene. With its smooth operation and fast strapping speed, the facility is now running like a well-oiled machine. Workers are more efficient, and products are securely strapped, resulting in happy customers and increased profits.

Critique and Review Style:

While the Automatic Strapping Machine offers numerous advantages, it is not without its limitations. Some users have reported occasional jams or errors in the machine’s operation. However, these issues are easily resolved with regular maintenance and proper training of operators. Overall, the benefits far outweigh the minor inconveniences, making the Automatic Strapping Machine a worthwhile investment.

How-to Guide Style:

If you are considering purchasing an Automatic Strapping Machine, here are some steps to guide you through the process:

1. Assess your packaging needs: Determine the volume and size of products you need to strap to choose the right machine model.

2. Research different brands and models: Consider factors such as reliability, ease of use, and after-sales support.

3. Request a demonstration: Contact suppliers and request a live demonstration to see the machine in action.

4. Compare prices and features: Evaluate different options and choose the one that best fits your budget and requirements.

5. Train your staff: Once you have purchased the machine, provide proper training to your staff to ensure safe and efficient operation.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert link to manufacturer’s website] strapping machine

“Efficient and Versatile Strapping Machines: Boost Productivity with Semi and Automatic Options”