Title: Efficient Pallet Wrapping Machines for Stable and Reliable Goods Packaging

Description:

Welcome to our informative video showcasing the exceptional capabilities of pallet wrapping machines, including the Pallet Wrapping Machine With Top. With its stable structure, high stability, long lifespan, and low failure rate, this machine revolutionizes the packaging process.

Introduction:

In this video, we delve into the world of pallet wrapping machines, focusing on their remarkable features and advantages. Whether you’re a business owner, warehouse manager, or simply curious about the latest packaging technology, this video will provide valuable insights.

Video Content:

1. Overview:

– Discover the advanced design and construction of pallet wrapping machines, ensuring stability and durability.

– Learn how these machines streamline the packaging process, saving time and effort.

– Understand the importance of ensuring consistent and secure wrapping to protect goods during transportation.

2. Key Features:

– Explore the stable structure of pallet wrapping machines, minimizing vibrations and ensuring reliable performance.

– Delve into the high stability of these machines, preventing damage and maintaining the integrity of wrapped goods.

– Learn about the impressive long lifespan of pallet wrapping machines, providing a reliable packaging solution for years.

– Examine the low failure rate, reducing downtime and maximizing productivity.

3. Operation Steps:

– Step 1: Prepare the pallet and goods for wrapping, ensuring proper alignment and stability.

– Step 2: Adjust the settings on the pallet wrapping machine to suit the specific requirements of your goods.

– Step 3: Activate the machine, allowing it to efficiently wrap the goods with precision.

– Step 4: Monitor the wrapping process to ensure optimal tension and coverage.

– Step 5: Safely remove the wrapped pallet and goods for transportation or storage.

Call to Action:

If you found this video informative and helpful, please consider liking, subscribing, and sharing it with others who may benefit from learning about efficient pallet wrapping machines. Don’t forget to leave your comments or questions below.

Additional Tags and Keywords:

pallet wrapping machine, pallet wrapping, efficient packaging, stable structure, reliable performance, long lifespan, low failure rate, goods packaging, packaging technology, warehouse management, transportation, secure wrapping, productivity improvement, machine operation, packaging process, advanced design.

Hashtags:

#palletwrappingmachine #efficientpackaging #goodsprotection #warehousing #packagingsolutions #productivityimprovement

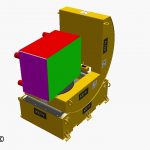

A tilter for a Pallet Wrapping Machine With Top is a device designed to rotate or tilt a pallet while it is being wrapped. This helps ensure that the top of the pallet is securely wrapped and provides additional stability during transportation or storage. Here is a basic tilter design:

1. Frame: Construct a sturdy frame using steel or aluminum beams to support the weight of the pallet and the wrapping machine. Ensure the frame is stable and has a flat surface to accommodate the pallet.

2. Rotation Mechanism: Install a motorized rotation mechanism at the base of the frame. This can be a hydraulic or electric motor connected to a gear system. The rotation mechanism should allow the frame to rotate smoothly and securely.

3. Pallet Support: Attach a pallet support platform to the frame. This platform should have adjustable arms that can accommodate different pallet sizes. The arms should securely hold the pallet in place during rotation.

4. Tilt Mechanism: Install a hydraulic or electric tilt mechanism on the platform. This mechanism should allow the platform to tilt up to a certain angle, typically around 90 degrees. The tilt mechanism should be controlled by a separate motor or hydraulic system.

5. Control Panel: Add a control panel to the tilter for easy operation. The control panel should include buttons or switches to control the rotation and tilt functions. It should also have safety features like emergency stop buttons and safety interlocks.

6. Safety Features: Incorporate safety features such as proximity sensors or safety switches to prevent accidents during operation. These features can detect the presence of objects or people in the tilter’s vicinity and automatically stop the rotation or tilt if necessary.

7. Integration with Wrapping Machine: Ensure that the tilter is compatible with the pallet wrapping machine. This may involve integrating the control systems of both machines or designing a separate control panel that can operate both the tilter and the wrapping machine simultaneously.

8. Testing and Maintenance: Before putting the tilter into use, thoroughly test its rotation and tilt functions to ensure smooth operation. Regular maintenance should also be performed to keep the tilter in optimal working condition.

Remember to consult with a professional engineer or technician before constructing or using a tilter for a Pallet Wrapping Machine With Top. They can provide expert advice and ensure that the tilter meets all safety standards and requirements. pallet wrapping machine

#Pallet #Wrapping #Machine #Top