If you’re in the market for a semi-automatic stretch wrapper, you’ve come to the right place. In this video, we’ll guide you through the proper installation process for a Robopac Rotary semi-automatic stretch wrapper. It’s important to follow instructions and safety guidelines to ensure a successful and hassle-free installation.

Before we dive into the installation process, let’s briefly discuss what a semi-automatic stretch wrapper is. A semi-automatic stretch wrapper is a machine used to wrap palletized loads with stretch film. It automates the process of securing and protecting the products on a pallet, making it more efficient and cost-effective.

Now, let’s get started with the installation process. Please note that this guide is specific to the Robopac Rotary semi-automatic stretch wrapper.

Step 1: Pre-Installation Preparation

Before installing the Robopac Rotary stretch wrapper, it’s crucial to prepare the area and gather all the necessary tools. Ensure that the installation site is clean, level, and free from any obstacles. Make sure you have all the required tools and equipment, such as a forklift or pallet jack, wrenches, and a power drill.

Step 2: Unpacking the Stretch Wrapper

Carefully unpack the Robopac Rotary stretch wrapper and ensure that all the components are present and undamaged. Check for any signs of shipping damage and report it to the supplier immediately if necessary.

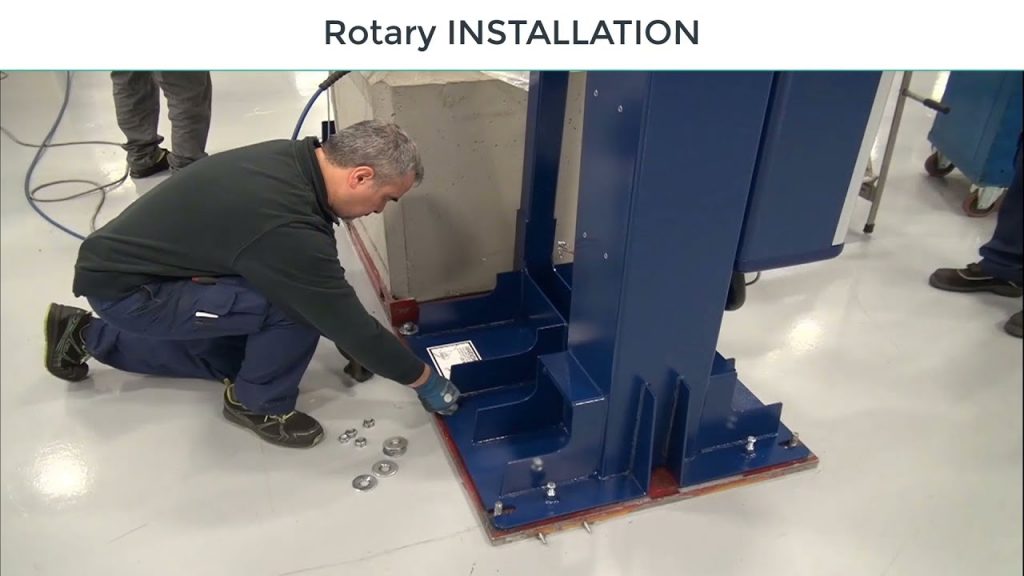

Step 3: Assembling the Base

Start by assembling the base of the stretch wrapper. Follow the provided instructions and use the appropriate tools to securely attach the base components. Ensure that the base is stable and level to prevent any instability during operation.

Step 4: Mounting the Control Panel

Next, mount the control panel in a convenient and accessible location. This panel allows you to control and adjust various settings of the stretch wrapper. Follow the instructions provided by Robopac to properly mount and connect the control panel.

Step 5: Installing the Film Carriage

The film carriage is an essential component of the stretch wrapper that holds and dispenses the stretch film. Install the film carriage according to the manufacturer’s instructions, making sure it is securely attached and aligned properly.

Step 6: Connecting Power and Air Supply

Connect the power and air supply to the stretch wrapper. Ensure that the power source meets the required specifications and that the air supply is clean and regulated. Follow the provided guidelines to properly connect these utilities.

Step 7: Testing and Calibration

Once all the components are installed and connected, it’s time to test and calibrate the stretch wrapper. Follow the instructions provided by Robopac to perform the necessary tests and calibrations. This step is crucial to ensure that the stretch wrapper operates smoothly and efficiently.

Step 8: Training and Safety

After the installation and calibration, it’s important to provide training to the operators who will be using the stretch wrapper. Train them on how to safely operate the machine and follow all safety guidelines. Emphasize the importance of wearing appropriate personal protective equipment (PPE) and adhering to the recommended operating procedures.

In conclusion, the installation of a Robopac Rotary semi-automatic stretch wrapper requires careful preparation, assembly, and calibration. By following the provided instructions and adhering to safety guidelines, you can ensure a successful and efficient installation process.

Check the coil packing solution with a leading manufacturer for a professional solution just here: [Link to manufacturer’s website]

Remember, safety should always be the top priority when working with machinery. If you have any questions or concerns during the installation process, don’t hesitate to contact the manufacturer or seek professional assistance. Happy wrapping! Stretch Wrapping Machine

“Effortless Installation Guide: Mastering the Rotary Semi-Automatic Stretch Wrapper”