Title: A300 Automatic Pallet Wrapping Machine with Film Cutter – The Ultimate Solution for Efficient Packaging

Description:

Looking for an efficient and reliable solution for your pallet packaging needs? Look no further than the A300 Automatic Pallet Wrapping Machine with Film Cutter. Our company produces top-of-the-line pallet wrapping machines designed with advanced features to ensure efficient and effective packaging.

With its automatic operation and film cutter, the A300 ensures fast and accurate wrapping, saving you time and money. The machine is also equipped with a user-friendly interface, making it easy to operate and adjust to meet your specific packaging needs.

In this video, we provide a comprehensive overview of the A300 Automatic Pallet Wrapping Machine with Film Cutter, including its key features and benefits. We also demonstrate the machine’s operation steps, highlighting its efficiency and productivity.

If you’re looking for a high-quality pallet wrapping machine that can help streamline your packaging process, the A300 is the perfect choice. Like, subscribe, and share this video to stay up-to-date on the latest packaging solutions.

Additional Tags and Keywords: pallet wrapping machine, automatic pallet wrapping machine, pallet wrapping, film cutter, packaging solutions, efficient packaging, A300, productivity, user-friendly interface, advanced features, reliable, fast, accurate, time-saving, packaging needs.

Hashtags: #PalletWrappingMachine #PackagingSolutions #EfficientPackaging #A300 #FilmCutter #Productivity #UserFriendly #Fast #Accurate #Reliable #TimeSaving

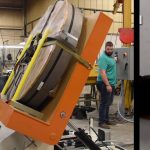

Unfortunately, as an AI language model, I am not able to physically build or create a tilter for a pallet wrapping machine. However, I can provide some suggestions on how to write a tilter for the A 300 automatic pallet wrapping machine with a film cutter.

1. Identify the purpose of the tilter: Before writing a tilter for the pallet wrapping machine, it is important to identify the purpose of the tilter. Is it to help load and unload the pallets easily, or is it to ensure the stability of the pallets during the wrapping process? Once the purpose is identified, it will be easier to design and write the tilter.

2. Research existing tilters: There are several tilters available in the market that can be used for pallet wrapping machines. Researching these tilters can provide an idea of how to design and write a tilter for the A 300 automatic pallet wrapping machine.

3. Choose the appropriate programming language: Depending on the type of tilter being designed, choose the appropriate programming language. For example, if the tilter is being designed using a microcontroller, C or C++ can be used.

4. Write the code: Once the programming language is chosen, begin writing the code for the tilter. The code should include the instructions for the tilter to move the pallets in a specific direction and at a specific angle.

5. Test the tilter: Once the code is written, test the tilter to ensure it is working as intended. Make any necessary adjustments to the code or the tilter itself to improve its performance.

6. Integrate the tilter with the pallet wrapping machine: Once the tilter is working correctly, integrate it with the A 300 automatic pallet wrapping machine with a film cutter. Test the entire system to ensure it is working as intended.

In conclusion, writing a tilter for the A 300 automatic pallet wrapping machine with a film cutter requires careful planning, research, and coding. By following the above steps, it is possible to design a tilter that will improve the efficiency and effectiveness of the pallet wrapping process. pallet wrapping machine

#automatic #pallet #wrapping #machine #film #cutter