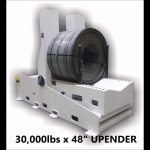

Title: Coil Upender: 6000 lbs Caldwell Coil Tipper/Upender Stock #14204

Description:

Welcome to our video showcasing the 6000 lbs Caldwell Coil Tipper/Upender Stock #14204. This heavy-duty coil upender is designed to safely and efficiently handle heavy coils in manufacturing and warehousing environments. In this video, we will take a closer look at the features and benefits of this coil upender and how it can help you streamline your coil handling operations.

Video Content:

– Overview of the 6000 lbs Caldwell Coil Tipper/Upender Stock #14204

– Key features and benefits of the coil upender

– How to safely operate the coil upender

– Tips for maximizing efficiency and minimizing downtime

– Real-life examples of the coil upender in action

Call to Action:

If you found this video helpful, please hit the like button and consider subscribing to our channel for more informative videos about industrial equipment. Don’t forget to share this video with your colleagues and friends who might find it useful.

Additional Tags and Keywords:

coil upender, coil handling equipment, heavy-duty coil upender, Caldwell coil tipper, industrial equipment, manufacturing equipment

Hashtags:

#coilupender #coilhandling #heavydutycoiltipper #Caldwellcoiltipper #industrialequipment #manufacturingequipment

Unfortunately, as an AI language model, I am not able to provide a tilter for a specific product without access to its specifications and design. However, here are some general steps that might be helpful in creating a tilter for a 6,000 lbs Caldwell coil tipper/upender:

1. Determine the center of gravity of the coil tipper/upender. This will help you design a tilter that can handle the weight and prevent any tipping or imbalance.

2. Choose the type of tilter that suits your needs. There are various types of tilters available, including hydraulic tilters, pneumatic tilters, and mechanical tilters. Each type has its advantages and disadvantages, so choose the one that fits your requirements and budget.

3. Determine the tilt angle required for your application. This will help you design the tilter to achieve the desired angle and prevent any damage to the coil tipper/upender or the load.

4. Design the tilter frame and mechanism. This includes selecting the materials and components required for the tilter, such as hydraulic cylinders, motors, pumps, hoses, and valves.

5. Test the tilter to ensure it meets your specifications and operates safely. This includes checking the load capacity, tilt angle, speed, and stability of the tilter.

6. Install the tilter on the coil tipper/upender and test it with a load to ensure it works correctly and safely.

Note: It is recommended to consult with a professional engineer or manufacturer to design and build a tilter for a specific application. Safety should always be the top priority when handling heavy loads. coil upender

#LBS #CALDWELL #COIL #TIPPER #UPENDER #STOCK