If you’re in the market for a pallet wrapping machine, you’ve come to the right place. In this article, we will be discussing the Pallet Wrapping Machine T1650F and providing you with an installation guide. Whether you’re a business owner looking to improve your packaging process or a distributor searching for new equipment to offer your customers, this article will provide you with all the information you need.

Pallet wrapping machines are an essential tool for businesses that deal with large quantities of goods. They provide a more efficient and cost-effective way to secure pallet loads, ensuring that your products arrive at their destination in perfect condition. The Pallet Wrapping Machine T1650F is a top-of-the-line machine that offers advanced features and reliable performance.

Installation Guide for the Pallet Wrapping Machine T1650F

Installing the Pallet Wrapping Machine T1650F is a straightforward process that can be completed in a few simple steps. Here’s a step-by-step guide to help you get started:

1. Unpacking the machine: Begin by carefully unpacking the machine and ensuring that all parts are included. Check for any signs of damage during shipping, and if necessary, contact the manufacturer for assistance.

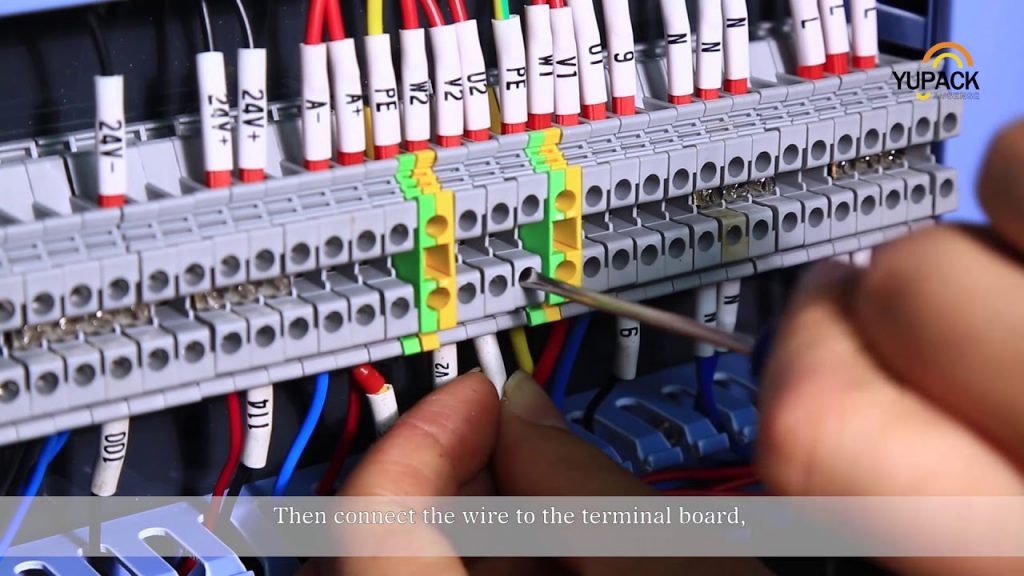

2. Assembling the machine: Follow the manufacturer’s instructions to assemble the machine. This typically involves attaching the base, mast, and turntable, as well as connecting any necessary electrical and pneumatic components.

3. Preparing the film roll: Load the film roll onto the machine’s film carriage. Make sure to properly align the film with the rollers to ensure smooth and consistent wrapping.

4. Adjusting the machine settings: Use the machine’s control panel to adjust settings such as wrapping speed, film tension, and number of wraps. These settings can be customized based on your specific packaging needs.

5. Testing the machine: Before using the machine to wrap actual pallets, perform a test run to ensure that everything is functioning correctly. Pay attention to the tension and stability of the wrapped pallets, making any necessary adjustments as needed.

6. Training and maintenance: Once the machine is installed and running smoothly, provide training to the operators who will be using it. Additionally, create a maintenance schedule to ensure that the machine remains in optimal condition and performs at its best.

Pallet Wrapping Machine for Sale: Your Solution for Efficient Packaging

Investing in a pallet wrapping machine is a smart choice for any business that wants to streamline its packaging process. The Pallet Wrapping Machine T1650F offers numerous benefits, including increased efficiency, reduced labor costs, and improved load stability. By automating the wrapping process, you can save time and resources, allowing your employees to focus on other important tasks.

In conclusion, the Pallet Wrapping Machine T1650F is a reliable and efficient solution for businesses in need of a pallet wrapping machine. With its easy installation process and advanced features, it is a valuable addition to any packaging operation. Don’t miss out on the opportunity to improve your packaging process and increase customer satisfaction.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Pallet Wrapping Machine

“Efficient Guide: Installing a Pallet Wrapping Machine & Finding One for Sale”