Have you ever wondered about the process of manual pallet strapping? Many companies still rely on manual strapping for a variety of reasons. However, with the advent of automatic strapping machines, this labor-intensive task can now be simplified and streamlined.

In this YouTube video, we will explore the concept of manual pallet strapping and how it compares to using an automatic strapping machine. We will delve into the benefits and drawbacks of each method, as well as provide insights into the technology behind automatic strapping machines.

Manual pallet strapping involves the manual application of straps or bands around a pallet to secure the goods in place. This method requires physical effort and can be time-consuming. Companies may choose manual strapping due to its low upfront cost or if they have a smaller volume of pallets to strap.

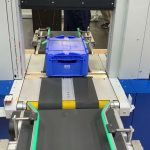

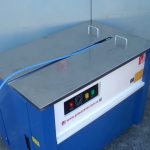

On the other hand, automatic strapping machines offer a more efficient and cost-effective solution. These machines automate the strapping process, reducing the need for manual labor and increasing productivity. With adjustable tension settings and precision control, automatic strapping machines ensure consistent and reliable strapping results.

One of the key advantages of using an automatic strapping machine is its ability to handle a higher volume of pallets in a shorter amount of time. This is particularly beneficial for companies with large-scale operations or those that require frequent pallet strapping. Additionally, the use of an automatic strapping machine can enhance worker safety by reducing physical strain and the risk of injuries.

The technology behind automatic strapping machines is continuously evolving. Advanced features such as automatic coil changing, self-threading mechanisms, and intuitive controls make these machines user-friendly and efficient. They are designed to accommodate various pallet sizes and can be easily integrated into existing production lines.

In conclusion, the introduction of automatic strapping machines has revolutionized the pallet strapping process. While manual strapping may still be suitable for certain scenarios, the advantages offered by automatic strapping machines are undeniable. Increased efficiency, improved productivity, and enhanced worker safety are just a few of the benefits that companies can enjoy by investing in this technology.

Check out our video to learn more about the benefits of automatic strapping machines and how they can transform your pallet strapping process. Discover the leading manufacturers and their coil packing solutions for a professional and reliable strapping solution.

Rewrite the “Check the coil packing solution with leading manufacturer for the professional solution just here:” strapping machine

“Efficient and Reliable Strapping Solutions: From Manual to Semi-Automatic and Automatic Pallet Strapping Machines”