Title: The Ultimate Guide to Pallet Wrapping Machines and Package Line Wrapping Systems

Description:

Are you tired of manually wrapping your pallets and packages? Look no further than Varipac’s pallet wrapping machines and package line wrapping systems! Our state-of-the-art machines are designed to streamline your packaging process and save you time and money.

Our pallet wrapping machines are built to last, using high-quality materials and advanced technology to ensure optimal performance. With customizable settings and user-friendly controls, our machines are easy to operate and can be tailored to fit your specific needs.

Our package line wrapping systems are the perfect solution for businesses with high-volume packaging needs. These systems are designed to handle a wide range of package sizes and shapes, making them ideal for a variety of industries.

At Varipac, we are committed to providing top-quality products and exceptional customer service. Our team of experts is always available to answer any questions you may have and to help you find the perfect pallet wrapping machine or package line wrapping system for your business.

So why wait? Improve your packaging process today with Varipac’s pallet wrapping machines and package line wrapping systems. Don’t forget to like, subscribe, and share our video for more great content!

Additional Tags and Keywords: pallet wrapping machine, package line wrapping system, packaging process, Varipac, user-friendly controls, customizable settings, high-volume packaging, exceptional customer service.

Hashtags: #palletwrapping #packagelinewrapping #Varipac #packagingprocess #customizablesettings #highvolumepackaging #exceptionalcustomerservice

As an AI language model, I can provide you with a description of how a tilter for pallet wrapping machine works.

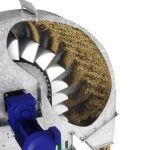

A tilter for pallet wrapping machine is a device that is designed to tilt the pallets at a certain angle to facilitate the wrapping process. The tilter is usually placed at the beginning of the wrapping line, and its main function is to rotate the pallets to a horizontal position to ensure uniform wrapping.

The tilter consists of a framework, a motor, and a set of rollers. The framework is usually made of steel and is designed to hold the pallets in place during the tilting process. The motor is responsible for providing the necessary power to rotate the pallets, while the rollers are used to guide the pallets along the tilter.

The pallets are loaded onto the tilter manually or automatically, depending on the design of the machine. Once the pallets are in place, the motor is activated, and the tilter begins to rotate the pallets at a certain angle. The angle of rotation depends on the design of the machine and can vary from 90 degrees to 180 degrees.

After the pallets have been rotated to the desired angle, they are held in place by the framework, and the wrapping process begins. The tilter remains in the same position throughout the wrapping process, and once the wrapping is complete, the pallets are rotated back to their original position for easy removal.

In summary, a tilter for pallet wrapping machine is an essential component of any pallet wrapping line. It helps to ensure that the pallets are wrapped uniformly and efficiently, and it can be customized to suit the specific needs of different industries. pallet wrapping machine

#pallet #wrapping #machine