Are you tired of spending endless hours manually wrapping pallets? Look no further than Robopac’s Masterplat semi-automatic stretch wrapper with Automatic Stretch Wrapping Machine. With its easy-to-operate control panel, this innovative solution will revolutionize your packaging process. In this article, we will explore the features and benefits of the Masterplat semi-automatic stretch wrapper, and guide you through the steps of operating the control panel.

The Masterplat semi-automatic stretch wrapper is designed to increase efficiency and productivity in your packaging operations. With its automatic stretch wrapping machine, it eliminates the need for manual labor and ensures consistent and secure wrapping of your pallets. This not only saves you time, but also reduces the risk of product damage during transportation.

Operating the control panel of the Masterplat is a breeze. With its user-friendly interface, even beginners can quickly learn how to operate the machine. The control panel allows you to easily adjust settings such as wrapping speed, film tension, and number of wraps. You can also choose from a variety of wrapping patterns to suit your specific packaging requirements.

To operate the control panel, simply follow these steps:

1. Power on the machine and ensure that it is securely connected to a power source.

2. Select the desired wrapping program from the control panel. The machine offers various pre-set programs for different pallet sizes and wrapping needs.

3. Adjust the wrapping speed and film tension according to your preferences. The control panel provides intuitive controls for easy adjustment.

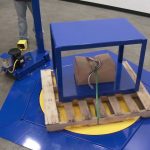

4. Place the pallet on the turntable and ensure that it is properly centered.

5. Press the start button on the control panel to initiate the wrapping process. The machine will automatically apply the stretch film around the pallet, securing it in place.

6. Once the wrapping is complete, the machine will stop automatically. You can then remove the wrapped pallet and repeat the process for the next one.

The Masterplat semi-automatic stretch wrapper offers several advantages over traditional manual wrapping methods. Firstly, it significantly reduces labor costs by eliminating the need for manual wrapping. This means that your employees can focus on more important tasks, leading to increased productivity and efficiency. Secondly, the automatic stretch wrapping machine ensures consistent and uniform wrapping, minimizing the risk of load shifting and product damage. Lastly, the machine’s intuitive control panel makes it easy for anyone to operate, reducing the need for specialized training.

In conclusion, the Masterplat semi-automatic stretch wrapper with Automatic Stretch Wrapping Machine is a game-changer in the packaging industry. Its easy-to-operate control panel, coupled with the automatic wrapping capabilities, will streamline your packaging process and save you time and money. Say goodbye to manual labor and hello to efficiency and productivity with the Masterplat. Try it today and experience the difference for yourself!

Check the coil packing solution with leading manufacturer for the professional solution just here. Stretch Wrapping Machine

“Efficiently Operating a Semi-Automatic Stretch Wrapper: Mastering the Control Panel and Automatic Wrapping Process”