Welcome to the fascinating world of KUKA robots at the Ramah Water Factory in Saudi Arabia. In this video, we will explore how these robots work hand in hand, or rather, arm in arm, to enhance the efficiency and precision of the water bottling process. With their incredible speed and accuracy, these High-Speed Industrial Robots have revolutionized the way water bottles are palletized.

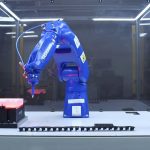

The Ramah Water Factory is a prime example of how advanced robotics technology has transformed the manufacturing industry. With three different KUKA robots in action, this factory has taken automation to a whole new level. These robots are equipped with cutting-edge technology that allows them to stack water bottles at lightning speed, ensuring a seamless production line.

The High-Speed Industrial Robots employed at the Ramah Water Factory have been specifically designed for high-speed stacking. Their precision and speed are truly awe-inspiring, as they effortlessly handle the delicate task of palletizing water bottles. With their robotic arms, these machines can swiftly and accurately place bottles onto pallets, optimizing the packaging process.

The use of High-Speed Industrial Robots in the water bottling industry has significantly increased efficiency and productivity. These robots can work tirelessly, day and night, without any compromise on quality. With their advanced sensors and programming, they ensure that each bottle is placed in the correct position, minimizing errors and maximizing output.

One of the key advantages of using KUKA robots for palletizing is their ability to adapt to various bottle shapes and sizes. Whether it’s a standard 500ml bottle or a larger 1-liter bottle, these robots can effortlessly handle the packaging process. This flexibility is crucial in a fast-paced manufacturing environment, where speed and adaptability are paramount.

Not only do these High-Speed Industrial Robots enhance efficiency, but they also improve workplace safety. By taking over the repetitive and strenuous task of palletizing, they reduce the risk of injuries to human workers. This allows employees to focus on more complex and value-added tasks, ultimately increasing job satisfaction and productivity.

The implementation of KUKA robots at the Ramah Water Factory showcases the potential of automation in the manufacturing industry. As technology continues to advance, we can expect even greater integration of robotics in various sectors. From assembly lines to packaging processes, robots are becoming an integral part of modern-day manufacturing.

In conclusion, the use of High-Speed Industrial Robots, such as the ones at the Ramah Water Factory, has revolutionized the way water bottles are palletized. With their speed, precision, and adaptability, these robots have significantly enhanced efficiency and productivity in the manufacturing process. As automation continues to evolve, we can expect more industries to embrace the power of robotics to streamline their operations.

Check the coil packing solution with a leading manufacturer for the professional solution just here. Industrial Robot

“Efficient Stacking: KUKA Robots Master High-Speed Palletizing of Water Bottles with Industrial Precision”