Title: Mastering the Art of Handling Equipment – A Comprehensive Guide to Material Handling Equipment(1)

Description:

Introduction:

Looking for a complete guide on handling equipment and material handling equipment(1)? Look no further! In this video, we have covered everything you need to know about mastering the art of handling equipment. Whether you’re new to the industry or looking to brush up on your skills, our video has got you covered.

Video Content:

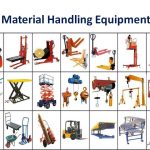

Our comprehensive guide covers everything from the basics of handling equipment to advanced techniques. We begin with an overview of material handling equipment(1), discussing the different types and their uses. We then dive into the key features and benefits of handling equipment, including safety measures and proper operation steps.

Our video also explores the different types of handling equipment, such as pallet jacks, forklifts, and conveyors. We provide an in-depth look at each type, including their uses, advantages, and disadvantages. We also highlight some of the key factors to consider when selecting the right handling equipment for your business, such as load capacity, maneuverability, and durability.

Our expert team of professionals also shares some industry insights and best practices for handling equipment, including tips for maintenance, safety, and efficient operation. We also cover some common mistakes and pitfalls to avoid when working with handling equipment.

Call to Action:

If you found this video helpful, please consider liking, subscribing, and sharing it with your colleagues and friends. Also, don’t forget to leave your comments and feedback in the comment section below.

Additional Tags and Keywords:

Handling equipment, material handling equipment(1), pallet jacks, forklifts, conveyors, load capacity, maneuverability, durability, maintenance, safety, efficient operation, industry insights, best practices.

Hashtags:

#HandlingEquipment #MaterialHandlingEquipment #PalletJacks #Forklifts #Conveyors #EfficientOperation #Safety #Maintenance #IndustryInsights #BestPractices.

A tilter for material handling equipment is a device that allows for the tilting of large and heavy materials, such as metal sheets or wooden boards, for easier transportation and manipulation. The tilter is typically mounted on a forklift or other material handling equipment and can be operated by a single person.

To create a tilter for material handling equipment, the following steps can be taken:

1. Design the tilter: The tilter should be designed to fit the specific material handling equipment it will be mounted on and the materials it will be used to transport. The tilter should be sturdy and durable enough to withstand the weight of heavy materials.

2. Choose materials: The tilter can be made of steel or other strong materials that can support heavy loads. The design should also include safety features such as locking mechanisms to prevent the materials from slipping or falling during transport.

3. Install the tilter: The tilter can be mounted on the material handling equipment using bolts or other fasteners. The tilter should be securely attached to the equipment to prevent any accidents.

4. Test the tilter: Before using the tilter, it should be tested to ensure that it is working properly and can safely handle the weight of the materials it will be used to transport.

5. Train operators: The operators of the material handling equipment should be trained on how to use the tilter safely and effectively. They should be familiar with the weight limits and safety features of the tilter to prevent accidents and injuries.

Overall, a tilter for material handling equipment can be a useful tool for transporting heavy materials and improving efficiency in a warehouse or manufacturing setting. By following these steps, a tilter can be designed and installed to meet the specific needs of a business. handling equipment

#Material #handling #equipment1