Check out our video on Rigidized® Metals’ innovative Rigid-tex® textured metals! These metals are designed to minimize surface contact area compared to flat metals, resulting in significant benefits for industrial handling machines and material handling in general.

In today’s fast-paced world of manufacturing and processing, efficiency is key. Every second counts, and any improvement, no matter how small, can make a huge difference in productivity. That’s where Rigidized® Metals’ Rigid-tex® textured metals come in.

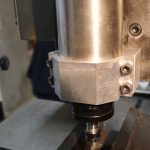

The Rigid-tex® process involves adding a unique texture to the surface of the metal, creating raised patterns that reduce the contact area with other surfaces. This may seem like a minor change, but it has a major impact on the performance of industrial handling machines.

One of the biggest challenges in material handling is minimizing friction and sticking. When flat metals come into contact with each other or with other surfaces, there is a large contact area, leading to increased friction and the potential for materials to stick. This can slow down the handling process, cause damage to the materials, and even result in costly downtime.

Rigid-tex® textured metals address this issue by reducing the contact area. The raised patterns on the metal’s surface create small points of contact, which significantly reduce friction and sticking. This allows industrial handling machines to move materials more smoothly and efficiently, resulting in faster processing times and increased productivity.

But the benefits don’t stop there. Rigid-tex® textured metals also offer improved grip and traction. The raised patterns provide a better grip for handling machines, reducing the risk of slippage and accidents. This is especially important in industries such as food processing, where maintaining a secure grip on materials is crucial for safety and quality control.

In addition to their practical advantages, Rigid-tex® textured metals also offer aesthetic benefits. The unique patterns and textures add a visually appealing element to industrial handling machines, enhancing their overall look and feel. This can be particularly advantageous for industries that prioritize aesthetics, such as retail or hospitality.

Furthermore, Rigidized® Metals’ Rigid-tex® textured metals are available in a wide range of materials, including stainless steel, aluminum, and galvanized steel. This ensures that customers can find the perfect solution for their specific needs, whether it’s in the food processing industry, material handling, or any other industrial application.

In conclusion, Rigidized® Metals’ Rigid-tex® textured metals are a game-changer for industrial handling machines and material handling in general. Their unique texture minimizes surface contact area, resulting in reduced friction, improved grip, and increased efficiency. Whether you’re looking to enhance productivity, ensure safety, or simply add a touch of style to your machines, Rigid-tex® textured metals are the ideal solution.

Check out our video to see Rigid-tex® textured metals in action and discover how they can revolutionize your industrial handling processes. Don’t miss out on the opportunity to optimize your operations with these innovative metals. Handling Machine

“Optimizing Efficiency and Safety: Expert Insights on Material Handling, Food Processing, and Industrial Handling Machines”