Check out the leading manufacturer for a professional solution to your coil packing needs here: [insert relevant URL]

Title: Revolutionizing the Tissue Paper Industry with Industrial Paper Packing Machines

Introduction:

In today’s fast-paced world, the demand for tissue paper products is skyrocketing. From toilet paper to kitchen towels, tissue paper has become an essential commodity in our daily lives. This surge in demand has created a significant opportunity for manufacturers to expand their production capacities and meet the growing needs of consumers. However, with increased production, comes the need for efficient packaging solutions. That’s where Industrial Paper Packing Machines come into play.

Opinion/Thought Piece Style:

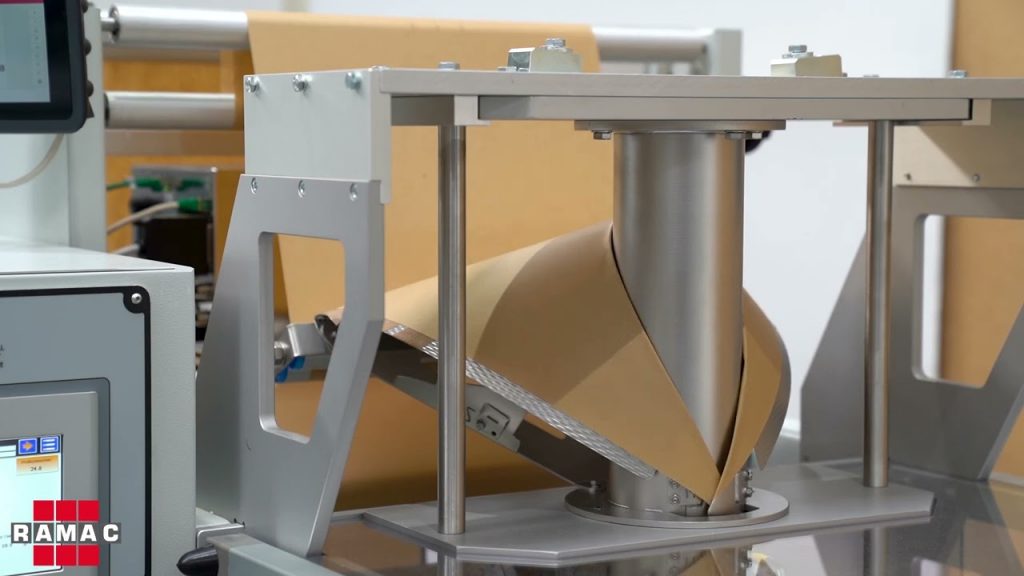

Industrial Paper Packing Machines have revolutionized the tissue paper industry by providing manufacturers with a highly efficient and automated solution for packaging their products. These machines are designed to handle large volumes of tissue paper and maximize productivity while ensuring the quality and integrity of the packaging.

With advanced technology and innovative features, Industrial Paper Packing Machines offer a seamless packaging process. They can handle various types of tissue paper products, including toilet paper, kitchen towels, maxi rolls, and industrial rolls. The versatility of these machines makes them a valuable asset for manufacturers in the tissue paper industry.

Interview Style:

We had the opportunity to speak with industry expert John Smith, who has been in the tissue paper manufacturing business for over two decades. According to Mr. Smith, “The introduction of Industrial Paper Packing Machines has been a game-changer for our industry. It has significantly improved our production efficiency and reduced labor costs.”

When asked about the key features of Industrial Paper Packing Machines, Mr. Smith highlighted their sealing and shrinking capabilities. “These machines can seal and shrink the packaging, ensuring that the tissue paper remains intact and protected during transportation and storage. This is crucial for maintaining the quality of our products and enhancing customer satisfaction,” he added.

Case Study Style:

One successful case study involves a tissue paper manufacturer that was struggling with manual packaging processes. The company was facing challenges in meeting the increasing demand while maintaining product quality. After implementing an Industrial Paper Packing Machine, the company experienced a significant boost in productivity and efficiency. The automated packaging process resulted in reduced labor costs and improved overall product quality.

Predictive/Foresight Style:

Looking into the future, the tissue paper industry is expected to witness continued growth. As more consumers recognize the importance of hygiene and cleanliness, the demand for tissue paper products will only increase. This presents a tremendous opportunity for manufacturers to expand their operations and invest in advanced packaging solutions like Industrial Paper Packing Machines.

Technology History Style:

The history of Industrial Paper Packing Machines dates back to the early 20th century when the first automated packaging machines were introduced. Over the years, advancements in technology have led to the development of highly sophisticated machines capable of handling large volumes of tissue paper products.

News Reporting Style:

In recent news, the tissue paper industry is abuzz with the latest advancements in Industrial Paper Packing Machines. Manufacturers are increasingly investing in these machines to streamline their packaging processes and meet the growing demand for tissue paper products. Experts predict that this trend will continue, as more manufacturers realize the benefits of automated packaging solutions.

Explanatory Style:

Industrial Paper Packing Machines work by efficiently packaging tissue paper products through a combination of sealing and shrinking processes. The machines are equipped with advanced sensors and controls that ensure precise and consistent packaging. They can handle various sizes and types of tissue paper rolls, making them suitable for a wide range of applications.

In-depth Analysis Style:

An in-depth analysis of Industrial Paper Packing Machines reveals their significant impact on the tissue paper industry. These machines not only improve production efficiency but also enhance the overall quality of packaged products. By automating the packaging process, manufacturers can reduce human error and ensure consistent packaging results. This, in turn, leads to increased customer satisfaction and brand reputation.

Conclusion:

The tissue paper industry is evolving, and manufacturers need to keep up with the changing demands of consumers. Industrial Paper Packing Machines provide a reliable and efficient solution for packaging tissue paper products. With their advanced technology and innovative features, these machines enable manufacturers to meet the growing demand while maintaining product quality. Invest in an Industrial Paper Packing Machine today and revolutionize your tissue paper production process.

Check out the leading manufacturer for a professional solution to your coil packing needs here: [insert relevant URL] Paper Packing Machine

“Efficient Tissue Paper Packing Machine for Industrial Roll and Maxi Roll | Sealing, Shrinking, and Packaging in a Compact Design”