Title: Ultimate Solution for Bagging All Types of Products – Premier Tech PTH-930 Series Automatic Bagging Machine

Description:

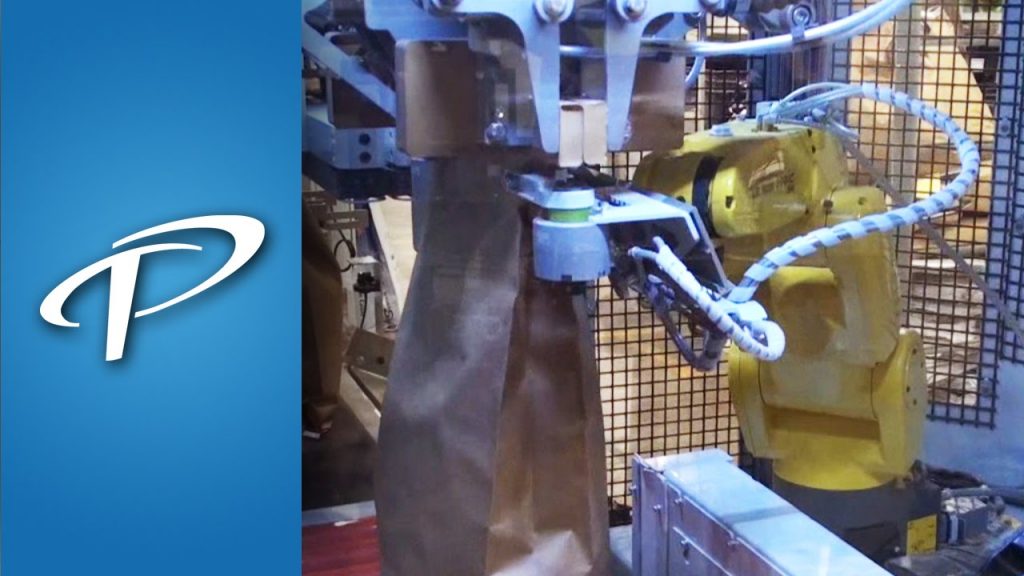

Welcome to our video showcasing the groundbreaking Automatic Bagging Packing Line, specifically the Premier Tech PTH-930 Series Automatic Bagging Machine with paper bags. Developed by Premier Tech, this state-of-the-art Open-Mouth Bagging Machine is a unique solution designed to revolutionize the bagging process for all types of products.

In this video, we provide an in-depth overview of the PTH-930 Series Automatic Bagging Machine, highlighting its exceptional features and functionalities. With its advanced technology and precision engineering, this machine offers unrivaled efficiency, accuracy, and versatility in bagging various types of products.

The PTH-930 Series Automatic Bagging Machine is designed to simplify and streamline bagging operations. Its user-friendly interface allows for seamless integration into existing production lines, ensuring a smooth workflow. This machine boasts a high bagging capacity, enabling rapid packaging of products while maintaining consistent quality.

Key Features:

1. Superior Bagging Performance: The PTH-930 Series guarantees precise bagging with minimal errors, ensuring product integrity and customer satisfaction.

2. Versatility: This bagging machine accommodates a wide range of products, including granular, powdery, and free-flowing materials.

3. Easy Maintenance: With its modular design and accessible components, the PTH-930 Series facilitates quick maintenance and minimizes downtime.

4. Ergonomic Design: The machine’s ergonomic features prioritize operator comfort and safety, enhancing overall efficiency and productivity.

5. Customizable Options: Premier Tech offers various customization options to tailor the bagging machine according to specific production requirements.

In this video, we demonstrate the operation steps of the PTH-930 Series Automatic Bagging Machine, showcasing its seamless bag filling, weighing, and sealing processes. Witness how this innovative solution significantly optimizes packaging efficiency, ultimately saving time and costs.

To stay updated with the latest developments in bagging technology and solutions, we kindly invite you to like, subscribe, and share our channel. By doing so, you will receive notifications whenever we release new videos that can benefit your business.

Additional Tags and Keywords: bagging machine, bagging packing line, Premier Tech bagging machine, PTH-930 Series, automatic bagging, paper bags, bagging technology, bagging process, bagging operations, bagging efficiency, bagging solutions.

Hashtags: #AutomaticBaggingMachine #BaggingPackingLine #PremierTechBagging #PTH930Series #BaggingTechnology #EfficientPackaging

A tilter for the Automatic Bagging Machine with paper bags (PTH-930 Series) is designed to tilt the machine at a specific angle for efficient bag loading and unloading. The tilter enhances the overall bagging process by reducing manual handling, increasing productivity, and ensuring proper bag placement. Here’s an example of a tilter for the PTH-930 Series:

1. Start by constructing a sturdy frame that fits the dimensions of the Automatic Bagging Machine. The frame should be made of strong and durable materials like steel to support the weight of the machine.

2. Install a motorized tilting mechanism at the base of the frame. This mechanism should be capable of smoothly tilting the machine at a predetermined angle. It can be powered by an electric motor or hydraulic system, depending on the specific requirements.

3. Integrate a control panel or interface to enable users to easily adjust and control the tilting angle. This panel should have user-friendly buttons or knobs to set the desired tilt angle.

4. Implement safety features such as limit switches or sensors to ensure that the tilter does not exceed the safe tilt angle. These safety mechanisms prevent any damage to the Automatic Bagging Machine or potential injury to operators.

5. Attach a conveyor system to the tilter to facilitate smooth bag loading and unloading. This conveyor should be positioned in such a way that it aligns perfectly with the tilted position of the machine, allowing bags to slide on and off with ease.

6. Test the tilter thoroughly to ensure its stability, functionality, and compatibility with the PTH-930 Series Automatic Bagging Machine. Conduct load capacity tests to confirm that it can handle the weight of the machine and bags without any issues.

7. Provide proper training to operators on how to use the tilter safely and efficiently. Emphasize the importance of following safety guidelines and precautions while operating the tilter.

By incorporating a tilter into the Automatic Bagging Machine setup, operators can save time and effort in bag loading and unloading processes. This addition improves overall productivity, reduces manual labor, and ensures accurate bag placement for efficient operations. coil packing line

#Automatic #Bagging #Machine #paper #bags #PTH930 #Series