Title: Rotary Arm Pallet Wrapping Machine X1000 & Smart Wasp – Fully Automatic Cut and Clamp Film High-Speed Wrapping Machine

Description:

In today’s fast-paced world, businesses are always looking for ways to optimize their operations and increase efficiency. One of the key areas of focus in the logistics industry is pallet wrapping. This is where the Rotary Arm Pallet Wrapping Machine X1000 and Smart Wasp come in.

These machines are fully automatic, with a cut and clamp film feature that makes pallet wrapping faster and more efficient. With high-speed wrapping capabilities, the Rotary Arm Pallet Wrapping Machine X1000 and Smart Wasp can wrap up to 40 pallets per hour, which is a massive improvement compared to manual wrapping methods.

The Rotary Arm Pallet Wrapping Machine X1000 and Smart Wasp are easy to operate, and their intuitive design means that even novice users can quickly master the machine. The machines come with a range of features, including adjustable wrapping tension, auto height detection, and a user-friendly control panel.

In this video, we cover everything you need to know about the Rotary Arm Pallet Wrapping Machine X1000 and Smart Wasp, including how to set up the machines, how to operate them, and their key features.

Key Takeaways:

– The Rotary Arm Pallet Wrapping Machine X1000 and Smart Wasp are fully automatic, with a cut and clamp film feature that makes pallet wrapping faster and more efficient.

– These machines can wrap up to 40 pallets per hour, which is a massive improvement compared to manual wrapping methods.

– The machines are easy to operate and come with a range of features, including adjustable wrapping tension, auto height detection, and a user-friendly control panel.

Call to Action:

If you found this video informative, please consider liking and subscribing to our channel. Don’t forget to share this video with your friends and colleagues to help them optimize their pallet wrapping operations.

Additional Tags and Keywords: pallet wrapping machine, rotary arm pallet wrapping machine, smart wasp, automatic cut and clamp film, high-speed wrapping, logistics, efficiency, adjustable wrapping tension, auto height detection, control panel.

Hashtags: #palletwrappingmachine #rotaryarmpalletwrappingmachine #smartwasp #cutandclampfilm #highspeedwrapping #logistics #efficiency #adjustablewrappingtension #autoheightdetection #controlpanel

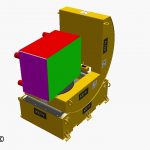

A tilter for the Rotary Arm Pallet Wrapping Machine X1000 is a device that helps to tilt the pallet during the wrapping process. This is done to ensure that the load is securely wrapped and prevents any damage during transportation.

To create a tilter for the X1000, follow these steps:

1. Determine the size and weight of the loads that will be wrapped using the machine.

2. Choose a tilter mechanism that is suitable for the weight and size of the load. This could be a hydraulic or pneumatic tilter, depending on the specific needs of the business.

3. Install the tilter mechanism onto the X1000 pallet wrapping machine. This can be done by attaching the tilter to the base of the machine using bolts or screws.

4. Connect the tilter mechanism to the control panel of the X1000. This will allow the operator to control the tilt angle and speed of the tilter.

5. Test the tilter to ensure that it is functioning properly and is capable of tilting the load to the desired angle.

6. Train operators on how to use the tilter safely and effectively.

By adding a tilter to the X1000, businesses can improve the efficiency and effectiveness of their pallet wrapping process while also reducing the risk of damage to the load during transportation. pallet wrapping machine

#Rotary #Arm #Pallet #Wrapping #Machine #X1000