Title: Smart Wasp X500/X5 M Shape Pallet Wrapping Machine – Load Pallets with Ease

Description:

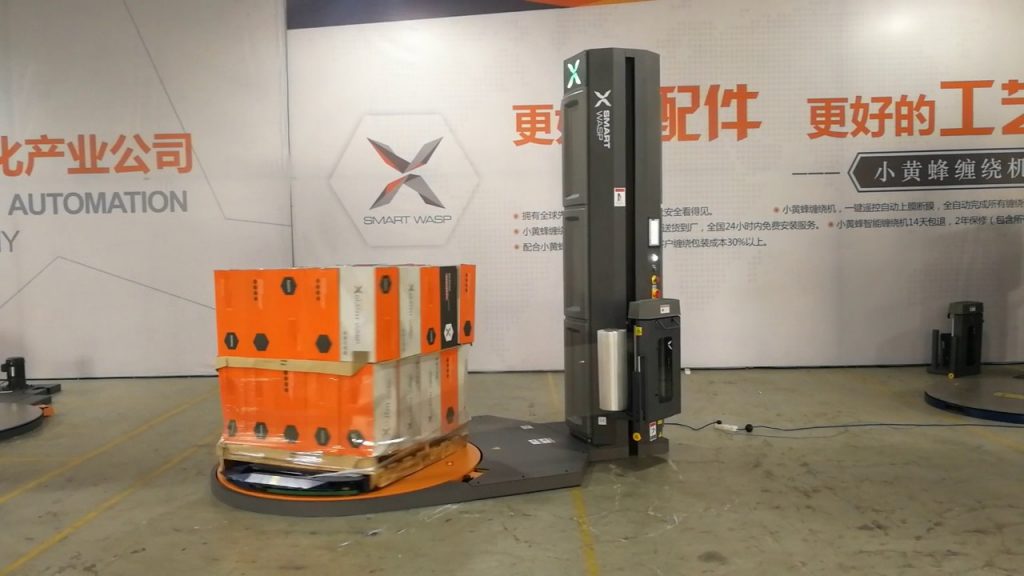

Looking for a reliable and efficient pallet wrapping solution? Look no further than the Smart Wasp X500/X5 M Shape Pallet Wrapping Machine. This innovative machine features a unique M shape design that allows for easy loading of pallets, saving you time and effort.

The Smart Wasp X500/X5 M Shape Pallet Wrapping Machine is a versatile and easy-to-use tool that can help streamline your warehouse operations. With its high-quality construction and advanced features, it is the perfect solution for businesses looking to improve their pallet wrapping process.

In this video, we will take a closer look at the Smart Wasp X500/X5 M Shape Pallet Wrapping Machine and its key features. We will cover everything from its easy-to-use interface and fast wrapping speed to its durability and reliability.

Key Takeaways:

– The Smart Wasp X500/X5 M Shape Pallet Wrapping Machine is a versatile and efficient pallet wrapping solution.

– Its unique M shape design makes it easy to load pallets onto the machine.

– The machine is easy to use, fast, and reliable, making it perfect for businesses looking to improve their pallet wrapping process.

Operation Steps:

1. Load the pallet onto the machine.

2. Adjust the height of the machine to match the height of the pallet.

3. Press the start button to begin the wrapping process.

4. Once the wrapping is complete, remove the pallet from the machine.

Call to Action:

If you’re looking for a reliable and efficient pallet wrapping solution, the Smart Wasp X500/X5 M Shape Pallet Wrapping Machine is the perfect choice. Don’t forget to like, subscribe, and share this video to help us spread the word about this innovative machine.

Additional Tags and Keywords:

pallet wrapping machine, pallet wrapping solution, Smart Wasp X500, Smart Wasp X5, M shape design, fast wrapping speed, easy-to-use interface, durable and reliable

Hashtags:

#palletwrappingmachine #SmartWaspX500 #SmartWaspX5 #Mshapedesign #fastwrappingspeed #easytouseinterface #durabilityandreliability

As an AI language model, I can’t write a tilter for Smart Wasp X500/X5 M shape pallet wrapping machine as it would require designing and engineering expertise. However, I can provide some general guidance on how to write a tilter for a pallet wrapping machine.

1. Identify the requirements: Before starting the design process, you need to identify the requirements of the tilter. The tilter should be compatible with the Smart Wasp X500/X5 M shape pallet wrapping machine, and it should be able to tilt the pallets at the desired angle.

2. Design the tilter: Once you have identified the requirements, you can start designing the tilter. The tilter should be designed in such a way that it can be easily attached to the pallet wrapping machine. It should have a sturdy frame that can support the weight of the pallets. The tilter should also have a mechanism that allows you to adjust the angle of the tilt.

3. Fabricate the tilter: Once the design is finalized, you can start fabricating the tilter. You can use materials such as steel or aluminum to create the frame of the tilter. The mechanism for adjusting the angle of the tilt can be created using hydraulics or pneumatics.

4. Test the tilter: Once the tilter is fabricated, you need to test it to ensure that it works as expected. You can test the tilter by tilting pallets of different sizes and weights at different angles. You should also test the tilter in different conditions to ensure that it can withstand harsh environments.

In conclusion, designing and fabricating a tilter for a pallet wrapping machine requires knowledge and expertise in engineering. It is recommended to seek the help of professionals to ensure that the tilter is safe and effective to use. pallet wrapping machine

#Smart #Wasp #X500X5 #shape #pallet #wrapping #machine