Title: The Ultimate Guide to Pallet Wrapping Machines – Everything You Need to Know!

Description:

Are you tired of inefficient and labor-intensive pallet wrapping methods? Look no further than our top-of-the-line pallet wrapping machine! In this video, we will give you a comprehensive overview of our #STRETCH WRAPPING MACHINE #PALLET WRAPPING MACHINE & STRETCH FILM WRAPPING MACHINE #packaging machine #EXPORT STRETCH WRAPPING MACHINE #stretch #Pallet … and how it can revolutionize your packaging process.

Introduction:

Say goodbye to messy and time-consuming pallet wrapping methods with our cutting-edge pallet wrapping machine. In this video, we will give you a detailed look at its features and operation steps, so you can see for yourself why it’s the perfect solution for your packaging needs.

Video Content:

We’ll begin by discussing the different types of pallet wrapping machines available and why our machine stands out from the rest. Then, we’ll take a closer look at its features, including its ability to wrap pallets quickly and securely, its user-friendly interface, and its easy-to-maintain design.

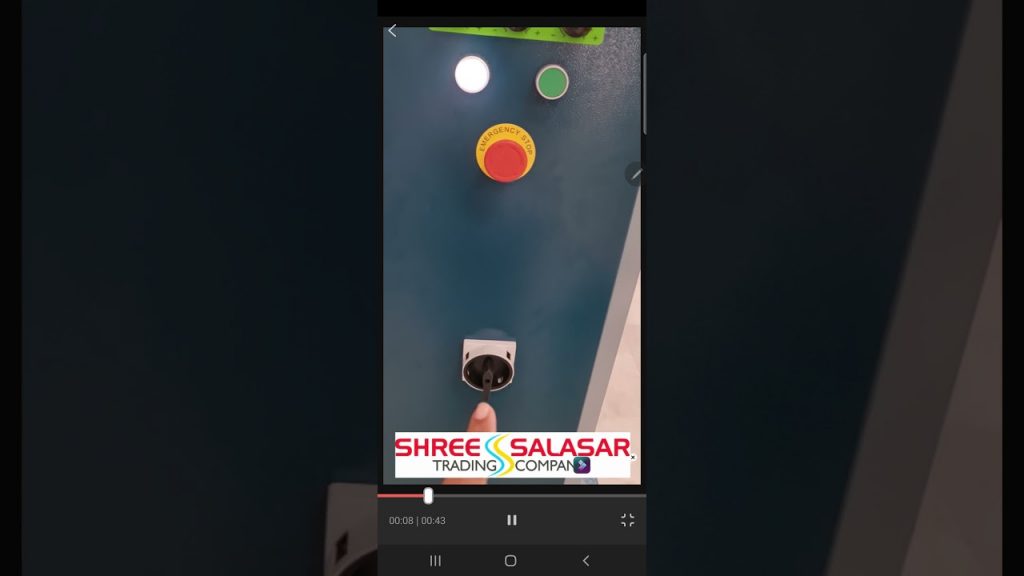

Next, we’ll walk you through the operation steps, showing you just how easy it is to load your pallet and let the machine do the work for you. We’ll also cover some key safety precautions you should take when using the machine.

Finally, we’ll give you some tips on how to maintain your pallet wrapping machine to ensure it stays in top condition for years to come.

Call to Action:

If you’re ready to streamline your packaging process and increase your efficiency, give our pallet wrapping machine a try! Don’t forget to like, subscribe, and share this video with others who could benefit from our machine.

Additional tags and keywords: pallet wrapping machine, stretch wrapping machine, packaging machine, stretch film wrapping machine, export stretch wrapping machine, pallet, wrapping, packaging, efficiency, labor-saving, maintenance, safety

Hashtags: #palletwrappingmachine #stretchwrappingmachine #packagingmachine #efficiency #labor-saving #safety #maintenance #wrapping #pallet

A tilter for a stretch wrapping or pallet wrapping machine is a device that helps to tilt the pallet or load in order to wrap it more efficiently. The tilter can be attached to the stretch wrapping or pallet wrapping machine or used as a separate device.

To build a tilter for a stretch wrapping or pallet wrapping machine, you will need the following materials:

– Steel or aluminum frame

– Hydraulic or pneumatic cylinders

– Motor

– Control system

– Safety sensors

– Mounting brackets

Here are the steps to build a tilter for a stretch wrapping or pallet wrapping machine:

1. Design the frame: The frame should be sturdy enough to support the weight of the load and made of steel or aluminum. The frame should also have mounting brackets to attach to the stretch wrapping or pallet wrapping machine.

2. Install hydraulic or pneumatic cylinders: The cylinders will be used to control the tilting motion of the tilter. The cylinders should be installed on the frame and connected to the control system.

3. Install the motor: The motor will be used to power the hydraulic or pneumatic cylinders. The motor should be installed on the frame and connected to the control system.

4. Install the control system: The control system will be used to monitor and control the tilting motion of the tilter. The control system should include sensors to ensure the safety of the operator.

5. Test the tilter: Once all the components are installed, test the tilter to ensure it is working properly. Test the sensors to ensure they are detecting any safety hazards.

A tilter for a stretch wrapping or pallet wrapping machine can help to increase efficiency and reduce the amount of material used in the wrapping process. It is a useful addition to any packaging line that deals with loads of varying shapes and sizes. pallet wrapping machine

#STRETCH #WRAPPING #MACHINE #PALLET #WRAPPING #MACHINE