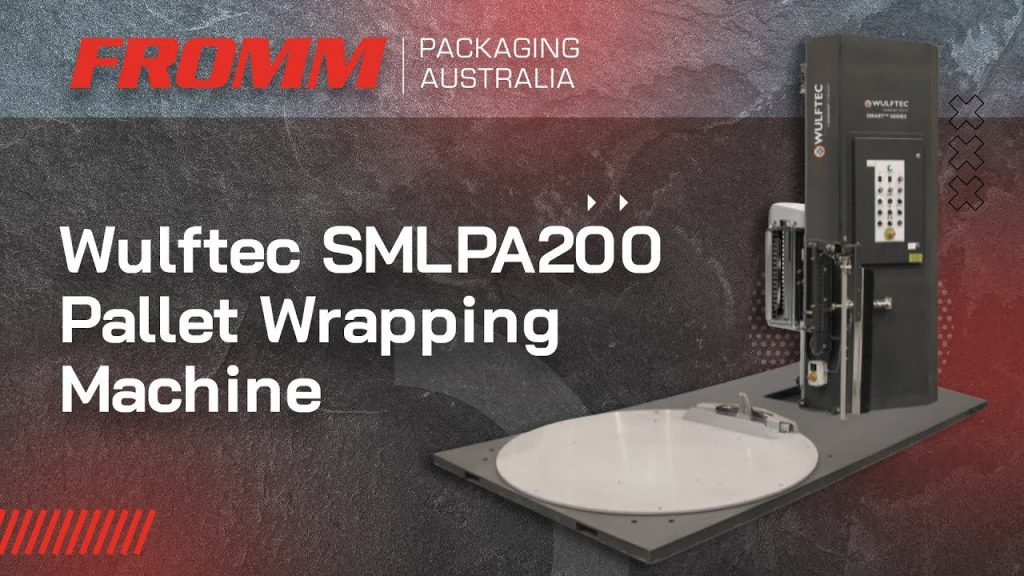

Title: Streamline Your Packaging Process: How to Load Stretch Film into SMLPA200 Pallet Wrapping Machine

Description:

Introduction:

Welcome to this informative video tutorial on how to effectively load stretch film into the SMLPA200 Pallet Wrapping Machine by FROMM. In this video, we will guide you through the step-by-step process of operating the Wulftec SMLPA200 Pallet Wrapping Machine, ensuring that your packaging process is streamlined and efficient.

Video Content:

In this comprehensive video tutorial, we will provide you with all the necessary instructions and insights to successfully load stretch film into the SMLPA200 Pallet Wrapping Machine. Our expert team will demonstrate the operation steps, highlighting key points and sharing valuable tips to optimize your packaging process.

1. Understanding the SMLPA200 Pallet Wrapping Machine:

Learn about the SMLPA200 Pallet Wrapping Machine’s features, benefits, and how it can enhance your packaging operations. Discover how this advanced machinery can save time, reduce labor costs, and improve load stability.

2. Preparing for Stretch Film Loading:

We will walk you through the essential preparations required before loading the stretch film into the machine. From ensuring the correct film type and dimensions to inspecting the machine for any maintenance needs, we will cover all the necessary steps to set the stage for successful packaging.

3. Loading Stretch Film into the Machine:

Follow our detailed instructions on how to properly load the stretch film onto the SMLPA200 Pallet Wrapping Machine. We will discuss the correct positioning of the film roll, securing it onto the machine’s spindle, and aligning it for optimal wrapping performance.

4. Adjusting Machine Settings:

Discover how to adjust the machine’s settings to accommodate different load sizes and wrapping requirements. We will guide you through adjusting the film tension, speed, and other important parameters to ensure the perfect wrap every time.

5. Operating the Machine:

Learn how to operate the SMLPA200 Pallet Wrapping Machine effectively, including starting the wrap cycle, monitoring the process, and troubleshooting common issues. Our step-by-step instructions will help you maximize productivity and minimize downtime.

Call to Action:

If you found this video tutorial helpful, please consider liking, subscribing, and sharing it with others who could benefit from this valuable information. Stay tuned to our channel for more insightful videos on pallet wrapping machines and other packaging solutions.

Additional Tags and Keywords:

pallet wrapping machine, stretch film loading, SMLPA200 Pallet Wrapping Machine, packaging process, streamline packaging, Wulftec SMLPA200, stretch film, packaging operations, load stability, machine settings, wrap cycle, troubleshooting

Hashtags:

#PalletWrappingMachine #StretchFilmLoading #PackagingProcess #StreamlinePackaging #SMLPA200 #WulftecSMLPA200 #StretchFilm #PackagingOperations #LoadStability #MachineSettings #WrapCycle #Troubleshooting

Title: Simplify Your Packaging Process: A Step-by-Step Guide to Loading Stretch Film into the SMLPA200 Pallet Wrapping Machine

Introduction:

Efficiently wrapping pallets with stretch film is essential for secure packaging and streamlined logistics. This guide provides a detailed walkthrough on how to load stretch film into the SMLPA200 Pallet Wrapping Machine, ensuring hassle-free and consistent packaging results.

Step 1: Prepare the Machine

Before starting, ensure that the SMLPA200 Pallet Wrapping Machine is properly set up and ready for operation. Make sure the machine is plugged in and in a stable position to prevent any accidents or interruptions during the process.

Step 2: Gather the Necessary Equipment

Collect all the required materials for loading stretch film into the machine. This includes the SMLPA200 Pallet Wrapping Machine, a roll of stretch film (preferably the appropriate size for the machine), and a sharp cutting tool.

Step 3: Locate the Film Dispenser

The SMLPA200 Pallet Wrapping Machine is equipped with a film dispenser located at the top of the machine. Locate this dispenser, ensuring it is easily accessible for loading the stretch film.

Step 4: Mount the Roll of Stretch Film

Insert the roll of stretch film onto the film dispenser. Ensure that the film roll is securely mounted and properly aligned with the dispenser’s guiding mechanism. This will help prevent the film from tangling or misfeeding during the wrapping process.

Step 5: Thread the Film through the Guiding Mechanism

Carefully thread the end of the stretch film through the guiding mechanism of the film dispenser. Follow the machine’s user manual or instructions for the specific threading process, ensuring the film is guided correctly to avoid any potential jams or issues.

Step 6: Secure the Film End

Once the film is threaded through the guiding mechanism, pull out a sufficient length of film from the dispenser to wrap around the pallet. Secure the end of the film to the pallet using a suitable method, such as a film clamp or by tucking it under the first wrap.

Step 7: Set the Parameters

Configure the desired wrapping parameters on the SMLPA200 Pallet Wrapping Machine, such as the number of rotations, tension, and speed. Adjust these settings according to the specific requirements of your packaging needs.

Step 8: Activate the Wrapping Process

Once the parameters are set, activate the wrapping process by pressing the designated start button or following the specified method as per the machine’s instructions. The machine will automatically begin wrapping the pallet with the loaded stretch film.

Step 9: Monitor and Inspect

While the machine is wrapping the pallet, keep a close eye on the process to ensure the stretch film is being applied smoothly and securely. Monitor for any potential issues, such as film slippage or tearing, and make necessary adjustments if needed.

Step 10: Finalize and Cut the Film

Once the wrapping process is complete, carefully cut the stretch film from the roll using a sharp cutting tool. Make sure to leave a sufficient amount of film for securing the end to the pallet, ensuring proper load containment.

Conclusion:

By following these step-by-step instructions, you can easily load stretch film into the SMLPA200 Pallet Wrapping Machine, streamlining your packaging process and enhancing the efficiency of your operations. Mastering this process will result in consistently well-packaged pallets, reducing the risk of damage during transportation and optimizing your overall logistics flow. pallet wrapping machine

#Streamline #Packaging #Process #Load #Stretch #Film #SMLPA200 #Pallet #Wrapping #Machine