Title: ME-476 Material Handling Equipment: A Comprehensive Overview

Description:

Introduction:

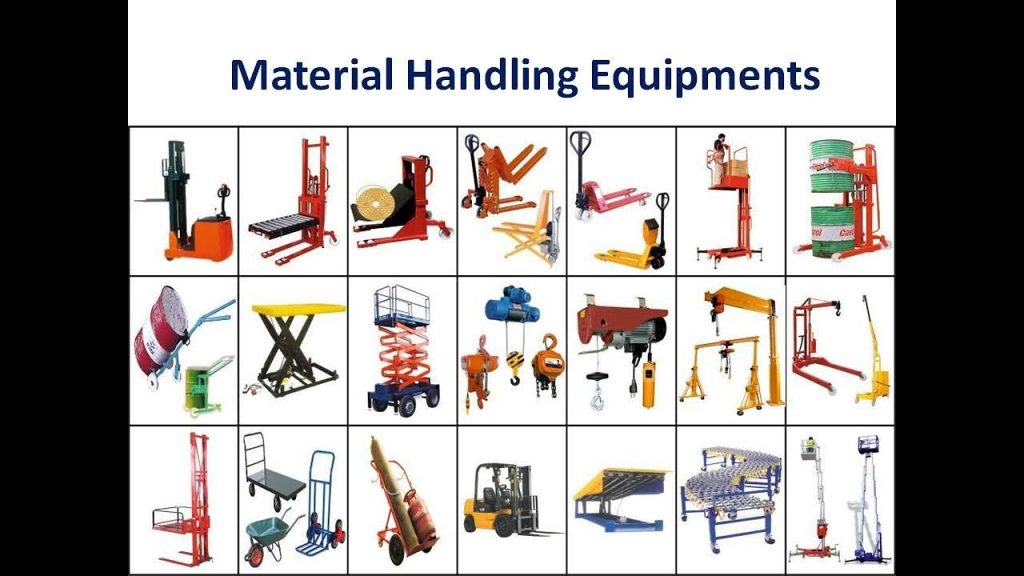

In this video, we provide a comprehensive overview of handling equipment, specifically focusing on ME-476 Material Handling Equipment’s. Whether you are familiar with material handling equipment or just starting to learn, this video provides valuable insights and key takeaways.

Video Content:

First, we define material handling equipment and its importance in various industries. Next, we dive into the ME-476 Material Handling Equipment’s, discussing its features, benefits, and common applications. We also cover the operation steps for this equipment, providing a step-by-step guide for efficient and safe usage.

Key Highlights:

– Definition and importance of material handling equipment

– Features and benefits of ME-476 Material Handling Equipment’s

– Common applications of this equipment

– Operation steps for efficient and safe usage

Call to Action:

If you found this video helpful, please consider liking, subscribing, and sharing it with others who may benefit from this information.

Additional Tags and Keywords:

material handling, material handling equipment, ME-476, equipment overview, handling equipment, industrial equipment, equipment operation, material handling solutions

Hashtags:

#materialhandling #ME476 #industrialequipment #equipmentoverview #handlingequipment #equipmentoperation #safetytips

Unfortunately, as an AI language model, I cannot physically create a tilter for ME-476 Material Handling Equipment. However, I can provide some information on what a tilter is and how it can be designed.

A tilter, also known as a tilt table or tilt platform, is a device used to tilt or rotate objects for easier handling, processing, or assembly. It typically consists of a flat surface supported by a frame and a mechanism that allows the surface to tilt or rotate to a desired angle. Tilters can be manual or powered, and they may have additional features such as safety locks, adjustable speed, and controls for precision positioning.

To design a tilter for ME-476 Material Handling Equipment, the following steps may be necessary:

1. Determine the weight and dimensions of the objects to be tilted, as well as the required tilt angle and speed. This will help determine the size and capacity of the tilter.

2. Choose the type of mechanism for tilting, such as hydraulic, pneumatic, or electric. This will depend on the power source available and the desired level of control.

3. Design the frame and support structure for the tilter, making sure it is sturdy enough to handle the weight and stress of the objects being tilted.

4. Select the appropriate controls and safety features, such as limit switches, emergency stop buttons, and locking mechanisms, to ensure safe operation.

5. Test and refine the tilter as needed, making sure it meets the desired specifications and safety standards.

Overall, designing a tilter for ME-476 Material Handling Equipment requires careful consideration of the specific needs and constraints of the application, as well as a thorough understanding of the mechanics and safety requirements of the device. It may be helpful to consult with experts in material handling and mechanical engineering to ensure the tilter is designed and built to the highest standards. handling equipment

#ME476 #Material #Handling #Equipments