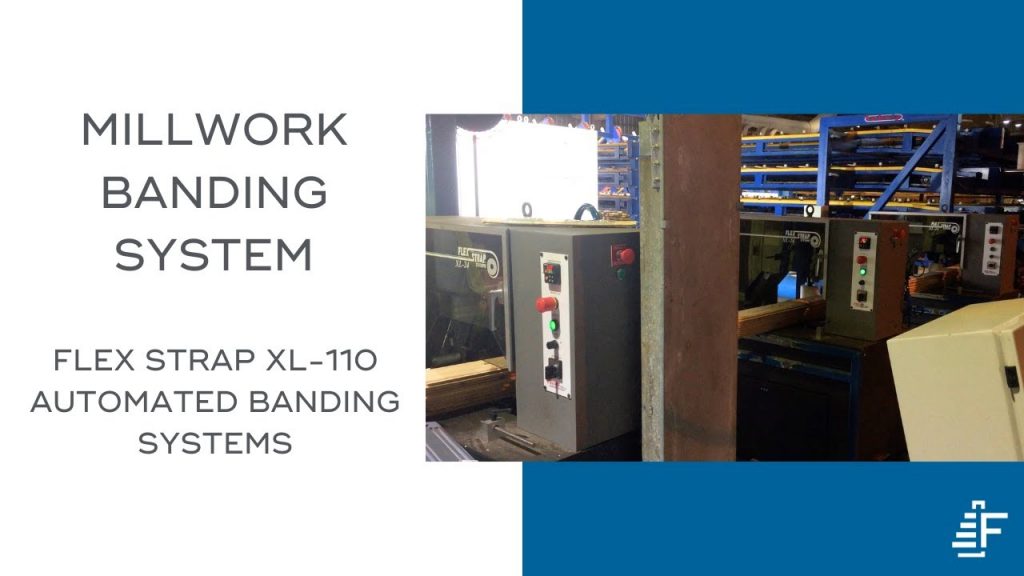

Title: Efficient Pallet Wrapping Machine: Securely Bundle and Protect Your Wood Millwork with Stretch Film

Description:

Introduction:

Discover the ultimate solution for securely bundling and protecting your valuable wood millwork pieces with our high-performance pallet wrapping machine. In this informative video, we will explore the benefits and ease of introducing stretch wrapping into your packaging process. Join us as we unveil the key features, operation steps, and important tips to efficiently utilize the stretch film banding lumber and strap.

Video Content:

Our comprehensive video provides a step-by-step guide on how to effectively bundle your wood millwork pieces using our pallet wrapping machine. With its advanced features and user-friendly design, this machine ensures optimal protection and stability during storage and transportation. Say goodbye to concerns about damage or shifting during handling!

Key Highlights:

1. Efficient Operation Steps: We will demonstrate the simple and intuitive operation process of our pallet wrapping machine, allowing you to quickly and effortlessly bundle your wood millwork pieces with stretch film. Streamline your packaging workflow and increase productivity with ease.

2. Enhanced Security: By utilizing stretch film banding lumber and strap, you can significantly enhance the security of your wood millwork bundles. The stretch film’s elasticity tightly holds the pieces together, preventing any movement or damage during transit.

3. Time-Saving Solution: Our pallet wrapping machine offers a time-saving solution for your packaging needs. With its automated functions, you can wrap multiple wood millwork pieces simultaneously, reducing labor costs and increasing efficiency.

Call to Action:

If you found this video helpful, don’t forget to like, subscribe, and share it with others in your industry. Stay updated with our latest videos by subscribing to our channel. For further information, visit our website and explore our range of packaging solutions designed to meet your specific needs.

Additional Tags & Keywords:

pallet wrapping machine, stretch film banding lumber, strap, bundle wood millwork, stretch wrapping, packaging process, secure packaging, efficient operation, enhanced security, time-saving solution, packaging solutions, productivity, storage, transportation, automated functions

Hashtags:

#PalletWrappingMachine #StretchFilmBandingLumber #SecurePackaging #WoodMillworkProtection #EfficientOperation #TimeSavingSolution #PackagingSolutions

Title: Efficient and Secure Stretch Film Banding Solution for Lumber Packaging

Introduction:

Stretch film banding is an essential packaging technique used in the lumber industry to secure and protect stacks of lumber during transportation and storage. This tilter aims to provide an efficient and secure solution for stretch film banding lumber, ensuring the utmost safety and convenience in the packaging process.

Purpose:

The purpose of this tilter is to streamline the stretch film banding process for lumber, reducing manual labor, improving efficiency, and ensuring the stability of packaged lumber, thereby preventing damage or accidents during transportation.

Features and Benefits:

1. Automated Tilt Function: The tilter is equipped with an automated tilt function that allows the user to adjust the angle of the lumber stack according to their requirements. This feature eliminates the need for manual handling, reducing the risk of injuries and improving overall efficiency.

2. Secure Stretch Film Application: The tilter incorporates a stretch film dispenser that ensures optimal tension and wrapping consistency. This helps to tightly secure the lumber stack, preventing any shifting or movement during transportation, and reducing the risk of damage.

3. Adjustable Banding Speed: The tilter offers adjustable banding speed settings, allowing the user to control the speed at which the stretch film is applied. This feature ensures that the stretch film is applied evenly and consistently, reducing waste and improving productivity.

4. Safety Measures: The tilter is equipped with safety features such as emergency stop buttons and sensors that detect any obstructions or malfunctions. These safety measures promote a safe working environment and prevent accidents during the packaging process.

5. User-Friendly Interface: The tilter is designed with a user-friendly interface, featuring intuitive controls and easy-to-understand instructions. This ensures that operators can quickly learn and operate the tilter efficiently, reducing training time and increasing productivity.

Conclusion:

The tilter for stretch film banding lumber offers a comprehensive solution to streamline the packaging process in the lumber industry. With its automated tilt function, secure stretch film application, adjustable banding speed, and safety measures, it provides an efficient and secure method for packaging lumber stacks, ensuring their safe transportation and storage. pallet wrapping machine

#Stretch #Film #Banding #Lumber