Title: Semi-Automatic Labeling Machine | Instruction Video & Overview of Round Bottle Labeling Machine

Description:

Introduction:

Welcome to our instructional video on the Semi-Automatic Labeling Machine. In this video, we provide a comprehensive overview of the machine’s structure, functions, and operation steps. Whether you are a beginner or an experienced user, this video will guide you through the process of labeling round bottles with ease.

Video Content:

1. Overview of the Semi-Automatic Labeling Machine:

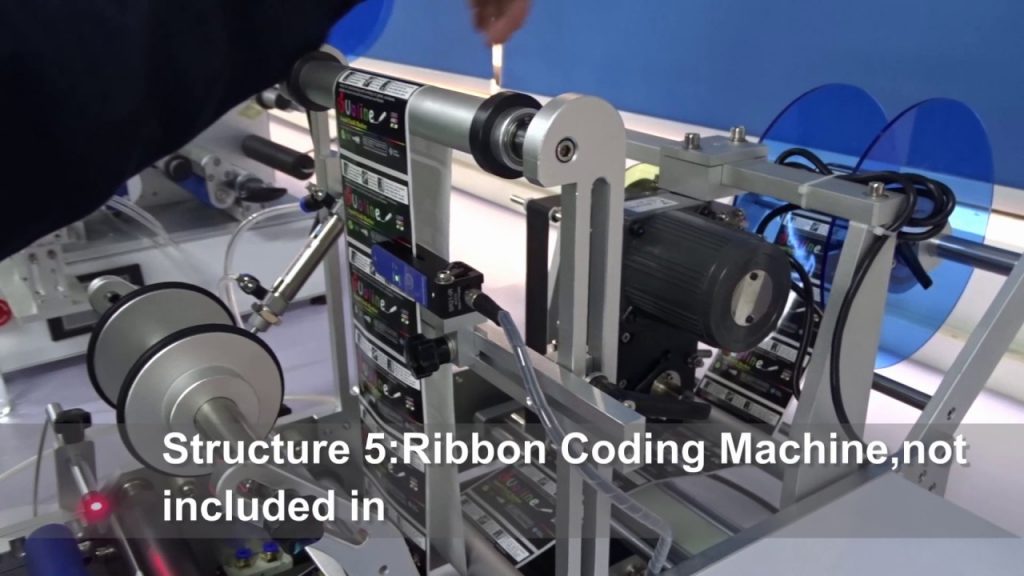

– We begin by introducing the various components and parts of the labeling machine, highlighting their functions and importance.

– From the label dispenser to the conveyor system, we cover all the essential elements that make this machine efficient and reliable.

2. Key Points and Highlights:

– Discover the key features and benefits of using our Semi-Automatic Labeling Machine, such as its versatility in handling round bottles of different sizes and materials.

– Learn about the machine’s capability to apply labels accurately and efficiently, ensuring a professional and aesthetically pleasing result every time.

3. Operation Steps:

– Follow our step-by-step guide as we demonstrate how to set up the labeling machine, load the labels and bottles, and adjust the settings for optimal labeling.

– Gain valuable insights into troubleshooting common issues and optimizing the machine’s performance for different labeling requirements.

Call to Action:

If you found this video helpful, give it a thumbs up and consider subscribing to our channel for more informative content on labeling machines and related industry insights. Don’t forget to share this video with your colleagues and friends who might benefit from it.

Additional Tags and Keywords:

Semi-Automatic Labeling Machine, Round Bottle Labeling Machine, Labeling Machine Structure, Labeling Machine Functions, Labeling Machine Operation, Labeling Machine Tutorial, Labeling Machine Tips, Labeling Machine Efficiency, Bottle Labeling, Round Bottle Labeling, Labeling Machine Demonstration, Labeling Machine Troubleshooting, Labeling Machine Setup.

Hashtags:

#SemiAutomaticLabelingMachine #RoundBottleLabeling #LabelingMachineTutorial #LabelingMachineTips #LabelingMachineDemo #LabelingMachineSetup #BottleLabeling #LabelingMachineEfficiency

Title: How to Operate a Semi-Automatic Round Bottle Labeling Machine

Introduction:

Welcome to our instructional video on how to operate a semi-automatic round bottle labeling machine. In this tutorial, we will guide you through the step-by-step process of using this efficient labeling machine to apply labels on round bottles accurately and efficiently. Let’s get started!

Step 1: Machine Setup

Begin by ensuring that the machine is placed on a stable surface and connected to a power source. Check that all the necessary parts and components, such as label rolls, are available and loaded correctly. Familiarize yourself with the machine’s control panel and settings.

Step 2: Adjusting the Machine

Before starting the labeling process, adjust the machine according to the bottle size and label dimensions. This includes setting the label position, bottle diameter, and label height using the machine’s adjustment knobs or digital controls. Make sure the machine is properly aligned and ready for operation.

Step 3: Loading Labels

Take the label roll and place it onto the label dispenser. Feed the leading edge of the label through the guide rollers and ensure it is properly aligned. Make sure the label roll is securely attached to prevent any movement during operation.

Step 4: Bottle Placement

Position the round bottles on the machine’s conveyor belt, ensuring they are evenly spaced and aligned. Adjust the bottle holder arms if necessary to accommodate different bottle sizes. Make sure the bottles are clean and dry before starting the labeling process.

Step 5: Label Application

Once the machine and bottles are prepared, activate the labeling process. Press the start button or activate the foot pedal to initiate the label application. The machine will automatically dispense and apply the labels onto the bottles as they pass through the labeling station. Ensure that the labels are applied accurately and without any wrinkles or air bubbles.

Step 6: Quality Control

Regularly monitor the labeling process to ensure the labels are being applied correctly. Check for any misalignment or defects and make necessary adjustments to the machine settings if required. It is essential to maintain high-quality labeling standards throughout the operation.

Step 7: Finishing Up

Once the labeling process is complete, remove the labeled bottles from the conveyor belt and inspect them for any issues. Clean the machine parts, remove any excess label waste, and properly store the label rolls for future use. Disconnect the machine from the power source and ensure it is safely stored.

Conclusion:

Congratulations! You have successfully learned how to operate a semi-automatic round bottle labeling machine. By following these steps, you can efficiently label round bottles with precision and accuracy. Remember to always refer to the machine’s user manual for specific instructions and safety guidelines. Thank you for watching!Labeling Machine

#Instruction #Video #Semi #automatic #Bottle #Labeling #Machine