Check out our website for more information on the best coil packing solutions in the industry.”

Title: Fully Automatic Production of Contact Plugs with Automatic Handling Machine

Introduction:

In today’s fast-paced manufacturing environment, efficiency and accuracy are key factors in ensuring successful production. The fully automatic production of contact plugs in a 4 cavity mold is a prime example of how technology can streamline the manufacturing process. By utilizing an automatic handling machine, this production method offers numerous benefits, including increased productivity, improved quality, and reduced labor costs. In this article, we will delve into the details of this innovative production technique and explore the advantages it brings to the table.

Section 1: The Importance of Automatic Handling Machines in Contact Plug Production

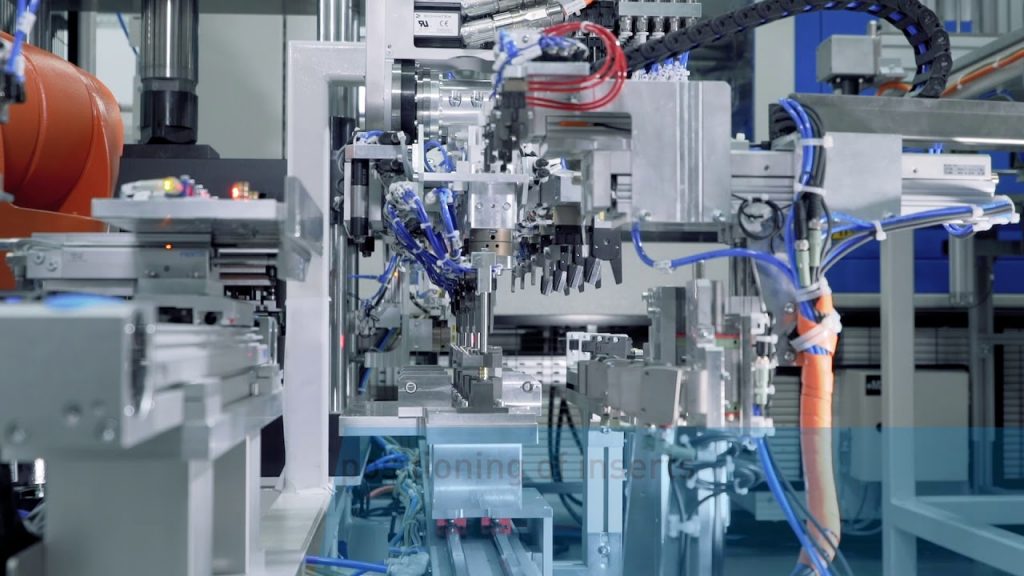

Automatic handling machines play a crucial role in the production of contact plugs. These machines are equipped with advanced technology that allows them to handle the assembly process with precision and efficiency. By automating the handling of components such as assembly plates, bushings, and pins, these machines eliminate the need for manual labor, resulting in significant time and cost savings.

Section 2: The Benefits of Fully Automatic Production

2.1 Increased Productivity

By incorporating a fully automatic production system, manufacturers can achieve higher production rates compared to manual assembly. The automatic handling machine works seamlessly with the 4 cavity mold, allowing for simultaneous production of multiple contact plugs. This leads to a significant increase in productivity and throughput.

2.2 Improved Quality

With automatic handling machines, the risk of human error is greatly minimized. These machines are programmed to perform each assembly step precisely, ensuring consistent quality throughout the production process. As a result, manufacturers can deliver contact plugs that meet the highest standards, free from defects or inconsistencies.

2.3 Reduced Labor Costs

One of the most significant advantages of fully automatic production is the reduction in labor costs. By eliminating the need for manual assembly, manufacturers can allocate their workforce to other tasks that require human expertise. This not only saves costs but also improves overall operational efficiency.

Section 3: Automatic Injection Molding of Contact Plugs with Automatic Handling 4×4 Inserts

The automatic injection molding process further enhances the efficiency of contact plug production. By integrating an automatic handling machine with a 4×4 insert system, manufacturers can achieve even higher production volumes. This process allows for the simultaneous injection of multiple contact plugs, maximizing output and reducing cycle times.

Section 4: The Role of Automatic Handling Machines in the Manufacturing Industry

Automatic handling machines have revolutionized the manufacturing industry in various sectors. Their versatility and efficiency make them invaluable assets in streamlining production processes. Whether it’s the production of contact plugs or other complex components, these machines offer a reliable and cost-effective solution.

Conclusion:

The fully automatic production of contact plugs in a 4 cavity mold, coupled with an automatic handling machine, is a game-changer for manufacturers in terms of efficiency and productivity. By embracing this innovative approach, manufacturers can optimize their production processes, reduce costs, and deliver high-quality products consistently. If you’re looking for a coil packing solution with leading-edge technology, be sure to explore our website for more information. Handling Machine

“Efficient Injection Molding of Contact Plugs: Streamlined Automation for 4 x 4 Inserts with Advanced Handling Machine”