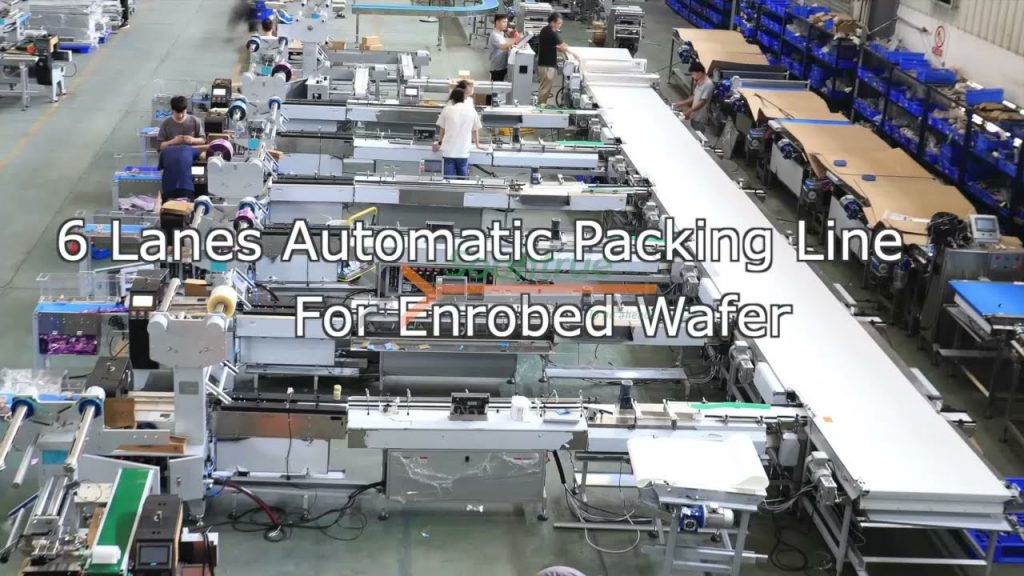

Title: 6 Lanes Automatic Packing Line For Enrobed Wafer – Efficient Packaging Solution | Soontrue Packing Machinery

Description:

Introduction:

Discover the cutting-edge 6 Lanes Automatic Packing Line for Enrobed Wafer offered by Soontrue Packing Machinery. This revolutionary packaging solution ensures efficient and precise packaging of enrobed wafers, optimizing productivity and minimizing manual labor. In this video, we provide a detailed overview of this automated packing line, highlighting its features, benefits, and operation steps.

Video Content:

Our video showcases the remarkable capabilities of the 6 Lanes Automatic Packing Line for Enrobed Wafer. With advanced technology and superior engineering, this packaging line offers seamless integration into your production process. It provides a high-speed packaging solution, ensuring the timely and accurate packaging of enrobed wafers.

Key Features:

– High Efficiency: The 6 lanes design enables simultaneous packaging of multiple products, significantly increasing packaging speed and overall efficiency.

– Precise Packaging: This automatic packing line ensures precise and consistent packaging, maintaining the integrity and quality of enrobed wafers.

– User-Friendly Interface: The intuitive control panel allows for easy operation and quick parameter adjustments, enhancing productivity and reducing downtime.

– Versatile Packaging Options: The line offers flexibility in packaging configurations, accommodating various sizes and shapes of enrobed wafers.

– Reliable Performance: Built with robust components and reliable mechanisms, this packing line guarantees long-lasting performance with minimal maintenance requirements.

Operation Steps:

1. Product Loading: Enrobed wafers are fed onto the conveyor belt, which transports them seamlessly to the packaging area.

2. Alignment and Orientation: The system aligns the wafers and ensures they are correctly positioned for packaging.

3. Packaging Material Handling: The packing line automatically dispenses the appropriate packaging material, precisely wrapping each wafer.

4. Sealing and Cutting: The system seals and cuts the packaging material, creating individual packs for each enrobed wafer.

5. Quality Control: Integrated sensors and inspection mechanisms ensure the packaging quality meets the highest standards.

6. Packaging Output: The finished packs are neatly stacked or collected for further processing, ready for distribution.

Call to Action:

If you are looking for an efficient and reliable packaging solution for enrobed wafers, the 6 Lanes Automatic Packing Line by Soontrue Packing Machinery is the ideal choice. Visit our official website for more information and to explore our extensive range of packaging machinery.

Additional Tags and Keywords:

#AutomaticPackingLine #EnrobedWaferPackaging #SoontruePackingMachinery #EfficientPackagingSolution #HighSpeedPackaging

Hashtags:

#AutomaticPackingLine #EnrobedWafer #PackagingSolution #SoontruePackingMachinery #EfficientPackaging #HighSpeedPackaging

Here is a sample tilter for a 6 Lanes Automatic Packing Line for Enrobed Wafer using Soontrue Packing Machinery:

1. Start by setting up the tilter machine according to the manufacturer’s instructions and ensure it is securely positioned within the packing line.

2. Ensure that the power supply is connected to the tilter and turn on the machine.

3. Adjust the speed and angle settings on the tilter machine based on the specific requirements of your enrobed wafer packing line. This may vary depending on the size and weight of the wafer products.

4. Prepare the enrobed wafer products to be tilted by placing them on a conveyor belt that leads to the tilter.

5. Activate the conveyor belt to move the enrobed wafer products towards the tilter machine. Ensure that the products are evenly spaced and aligned on the conveyor belt.

6. As the wafer products reach the tilter machine, the machine will automatically tilt them at the specified angle. The machine should have sensors or detectors to detect the presence of the products and initiate the tilting process.

7. Once tilted, the enrobed wafer products will be guided by the tilter machine onto another conveyor belt or packaging material for further processing.

8. Ensure that the tilted wafer products are properly aligned and positioned on the conveyor belt or packaging material before moving them to the next stage of the packing line.

9. Regularly monitor the tilter machine’s performance to ensure it is functioning properly. Check for any blockages, malfunctions, or irregularities that may affect the tilting process.

10. Follow the manufacturer’s recommended maintenance schedule to keep the tilter machine in optimal condition. This may include cleaning, lubricating, and replacing any worn-out parts.

Remember to always follow the safety guidelines provided by the manufacturer when operating the tilter machine. coil packing line

#Lanes #Automatic #Packing #Line #Enrobed #WaferSoontrue #Packing #Machinery