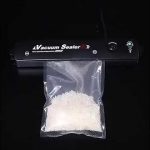

Title: Efficient Semi-Automatic Food Packing Machine | Cream Paste Filling with Heating and Stirring

Description:

Welcome to Blueland, the leading provider of packaging machinery solutions. In this video, we present our state-of-the-art Semi-Automatic Food Packing Machine, designed to streamline the packaging process and ensure efficiency in your production line. Additionally, we showcase our remarkable Semi-Automatic Filling Machine for Cream, which offers precise filling capabilities, and our innovative Cream Paste Filling Machine with Heating and Stirring, perfect for maintaining optimal consistency.

Our Semi-Automatic Food Packing Machine is meticulously engineered to meet the demands of modern food packaging operations. With its semi-automatic functionality, it strikes the ideal balance between automation and manual control. This machine is highly versatile and can efficiently handle various food products, ensuring accurate weighing, filling, and sealing processes. Its user-friendly interface allows for easy operation and adjustment, minimizing downtime and maximizing productivity.

The Semi-Automatic Filling Machine for Cream is a game-changer in the cosmetic and food industries. It provides exceptional accuracy and consistency when filling cream-based products, ensuring uniform distribution and professional packaging. Its heating and stirring capabilities further enhance the process, guaranteeing the perfect texture and quality of the final product. This machine is a valuable asset for businesses seeking to optimize their cream production and packaging.

Moreover, our Cream Paste Filling Machine with Heating and Stirring takes the art of cream-based product packaging to a whole new level. This advanced machine not only fills containers with precision but also incorporates heating and stirring functionalities to maintain the desired viscosity and consistency of the cream paste. Whether you’re packaging lotions, sauces, or other viscous substances, this machine ensures excellent results and customer satisfaction.

At Blueland, we are committed to delivering cutting-edge packaging machinery solutions that empower businesses to thrive in a competitive market. Our Semi-Automatic Food Packing Machine and specialized cream filling machines offer unmatched efficiency, reliability, and versatility. Join our satisfied customers by incorporating our innovative solutions into your production line today.

Don’t forget to like, subscribe, and share this video to stay updated with our latest packaging machinery solutions. For more information and to explore our full range of products, visit our website.

Additional Tags: food packing machine, cream filling machine, cream paste filling, heating and stirring, packaging machinery, semi-automatic machine, efficient packaging, precise filling, cream production, viscosity control, packaging solutions, Blueland

Hashtags: #FoodPackingMachine #CreamFilling #PackagingMachinery #EfficientPackaging #Blueland

Here is a sample tilter for a semi-automatic filling machine for cream:

Title: Semi-Automatic Cream Filling Machine Tilter

Introduction:

The semi-automatic cream filling machine tilter is a crucial component of the cream filling process. It ensures precise and efficient filling of cream into containers, optimizing production output and minimizing product wastage. This tilter is designed to streamline the cream filling process, providing ease of operation and consistent results. In this tilter, we will explore its features, benefits, and working mechanism.

1. Features:

– Sturdy Construction: The tilter is built with durable materials to withstand the demands of heavy-duty cream filling operations.

– Adjustable Angle: It allows for the adjustment of the tilter’s angle to accommodate various container sizes and shapes, ensuring accurate and efficient filling.

– Easy Operation: The tilter features a user-friendly interface, allowing operators to control the angle and speed of the tilter with ease.

– Safety Measures: The tilter is equipped with safety features such as emergency stop buttons and protective covers to ensure operator safety during operation.

2. Benefits:

– Increased Efficiency: The tilter enables faster and more efficient cream filling, reducing production time and maximizing output.

– Consistent Filling: By maintaining a precise angle and speed, the tilter ensures consistent filling of cream into containers, eliminating variations in product quantity.

– Reduced Product Wastage: The tilter’s accurate filling mechanism minimizes product wastage, optimizing resource utilization and reducing costs.

– Easy Integration: The tilter can be easily integrated into existing cream filling lines, enhancing overall productivity without extensive modifications.

3. Working Mechanism:

– The operator places the containers under the tilter’s filling nozzle.

– Using the control panel, the operator adjusts the desired filling angle and speed.

– Once the settings are confirmed, the tilter automatically starts the filling process.

– Cream is dispensed from the nozzle into the containers at the precise angle and speed, ensuring consistent filling.

– Once the containers are filled, the tilter stops automatically, and the operator can remove the filled containers for further processing or packaging.

Conclusion:

The semi-automatic cream filling machine tilter offers a reliable and efficient solution for cream filling operations. Its adjustable angle, easy operation, and safety features make it an essential component in cream filling lines. By utilizing this tilter, manufacturers can achieve higher productivity, consistent filling results, and reduced product wastage.Food Packing Machine

#Semi #automatic #filling #machine #Cream