Title: Enhance Efficiency with the Semi-Automatic Labeling Machine for Cosmetic Soft Tubes

Description:

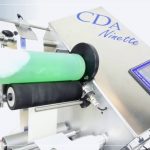

Welcome to our YouTube video showcasing the remarkable capabilities of the Semi-Automatic Labeling Machine for Cosmetic Soft Tubes. As a leading provider in the industry, we strive to offer high-quality labeling solutions that streamline the packaging process for cosmetic products.

Introduction:

In this video, we present the Semi-Automatic Labeling Machine designed specifically for labeling cosmetic soft tubes. Our state-of-the-art machine revolutionizes the labeling process, ensuring accuracy and efficiency while maintaining the integrity of your products.

Video Content:

1. Key Highlights:

– Experience seamless and precise label application with our advanced machine.

– Increase productivity by reducing labeling time and minimizing errors.

– Preserve the aesthetics of your cosmetic soft tubes with accurate label placement.

– Enjoy the flexibility of labeling various tube sizes and shapes effortlessly.

2. Operation Steps:

– Step 1: Prepare your cosmetic soft tubes for labeling.

– Step 2: Adjust the machine settings according to your label size and tube specifications.

– Step 3: Load the labels into the machine and ensure proper alignment.

– Step 4: Activate the machine and witness the automatic labeling process in action.

– Step 5: Inspect the labeled tubes for perfection and make necessary adjustments if required.

Call to Action:

If you want to optimize your labeling process and enhance productivity, the Semi-Automatic Labeling Machine for Cosmetic Soft Tubes is the perfect solution. Don’t forget to like, subscribe, and share this video to stay updated with the latest labeling technologies in the industry.

Additional Tags and Keywords:

labeling machine, semi-automatic machine, cosmetic soft tubes, labeling solution, packaging process, accuracy, efficiency, label placement, productivity, tube sizes, tube shapes, advanced machine, label application, labeling time, minimize errors, aesthetic preservation, flexible labeling, tube specifications, automatic labeling process, optimize labeling process, enhance productivity, latest labeling technologies.

Hashtags:

#LabelingMachine #CosmeticSoftTubes #PackagingProcess #Efficiency #Productivity #AutomatedLabeling #LabelingSolution #LabelApplication #TubeLabeling #StreamlinedProcess

Here’s a sample tilter for a semi-automatic labeling machine for cosmetic soft tubes:

Title: Semi-Automatic Labeling Machine for Cosmetic Soft Tube Tilter

Introduction:

The semi-automatic labeling machine for cosmetic soft tubes is a crucial component in the cosmetic industry, ensuring accurate and efficient labeling of soft tubes. The purpose of this tilter is to describe the key features and benefits of this labeling machine, highlighting its importance in the cosmetic industry.

1. Efficient Tube Orientation:

The tilter is equipped with advanced technology that allows for precise and efficient tube orientation. It ensures that the tubes are correctly positioned, enabling accurate labeling, eliminating errors, and reducing wastage.

2. Adjustable Label Placement:

The labeling machine’s tilter offers adjustable label placement options, allowing for flexibility in labeling different sizes and shapes of cosmetic soft tubes. It ensures that the labels are precisely aligned, improving the overall packaging aesthetics and brand image.

3. Ease of Operation:

The tilter is designed to be user-friendly, making it easy for operators to handle and operate the machine. Its intuitive controls and ergonomic design facilitate quick set-up and effortless tube loading, reducing downtime and increasing productivity.

4. High-Speed Labeling:

With its efficient tilter mechanism, the labeling machine can achieve high-speed labeling of cosmetic soft tubes. This feature enables manufacturers to optimize their production processes, meet demanding deadlines, and enhance overall efficiency.

5. Versatility and Compatibility:

The tilter is compatible with a wide range of cosmetic soft tubes, accommodating varying sizes, shapes, and materials. This versatility ensures that the labeling machine can be utilized for different product lines, providing flexibility for cosmetic manufacturers.

6. Robust Construction and Durability:

The tilter is constructed using high-quality materials, ensuring its durability and longevity. It can withstand the demanding nature of the cosmetic industry, providing reliable and uninterrupted performance for an extended period.

7. Accurate Label Placement:

The tilter ensures precise label placement on the cosmetic soft tubes, aligning the labels with precision. This accuracy enhances the overall product presentation, contributing to the brand’s credibility and customer satisfaction.

Conclusion:

The tilter for the semi-automatic labeling machine plays a vital role in the cosmetic industry, providing efficient, accurate, and high-speed labeling of soft tubes. Its adjustable label placement, ease of operation, compatibility, and robust construction make it an essential component for cosmetic manufacturers, enhancing their productivity and product presentation. With the tilter’s capabilities, manufacturers can streamline their labeling processes, maintain a competitive edge, and meet the ever-growing demands of the cosmetic market.Labeling Machine

#Semi #Automatic #Labeling #Machine #Cosmetic #Soft #Tube